Low-density heat-resistant iron-based alloy and preparation method thereof

An iron-based alloy and low-density technology, which is applied in metal processing equipment, coating, transportation and packaging, etc., can solve the problem that it cannot meet the requirements of high power density engine cylinder head materials, and is not suitable for high power density diesel engine cylinder head materials. Working conditions, performance degradation and other problems, to achieve the effect of small powder particle size, improve mechanical properties and thermophysical properties, and reduce density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

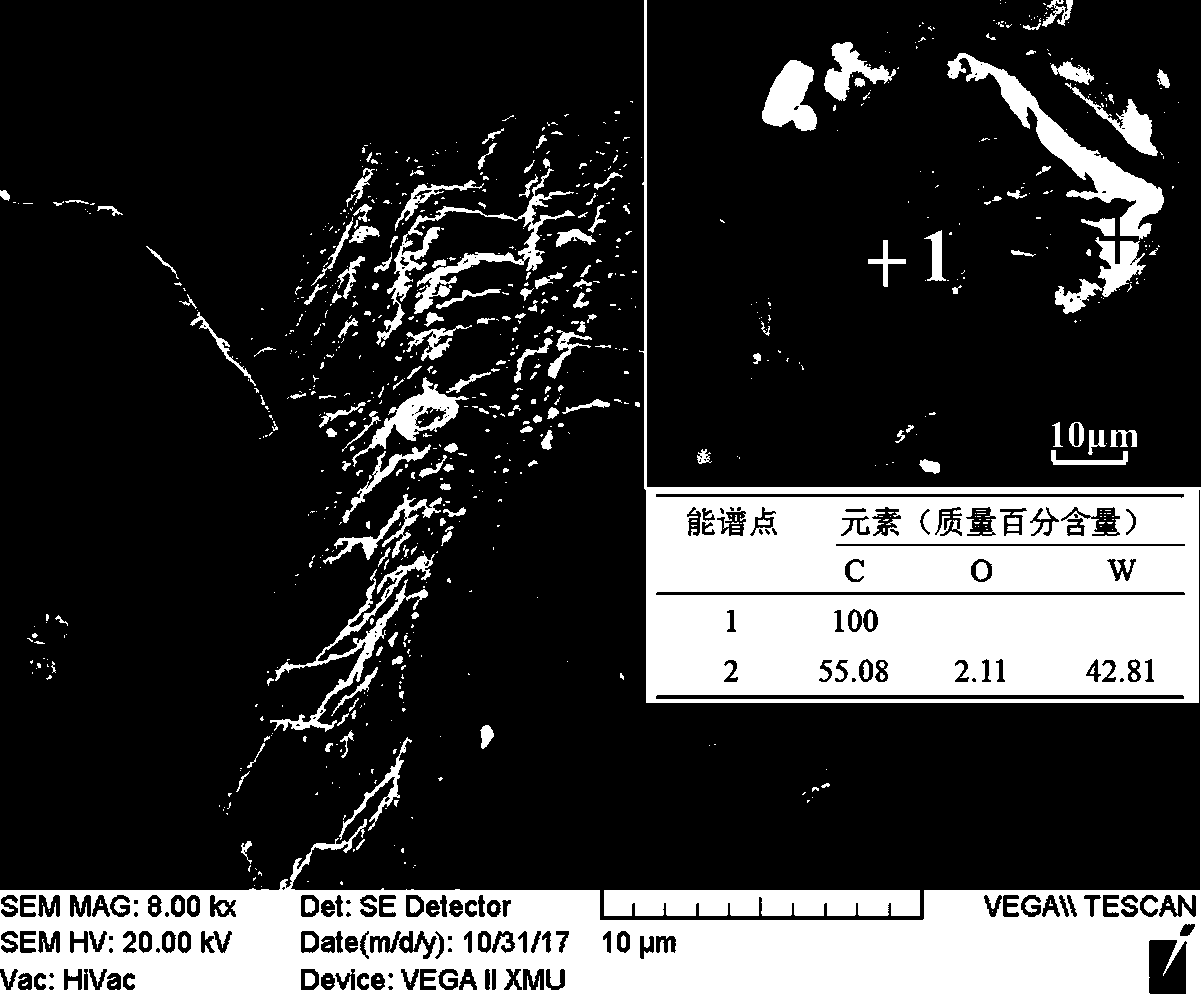

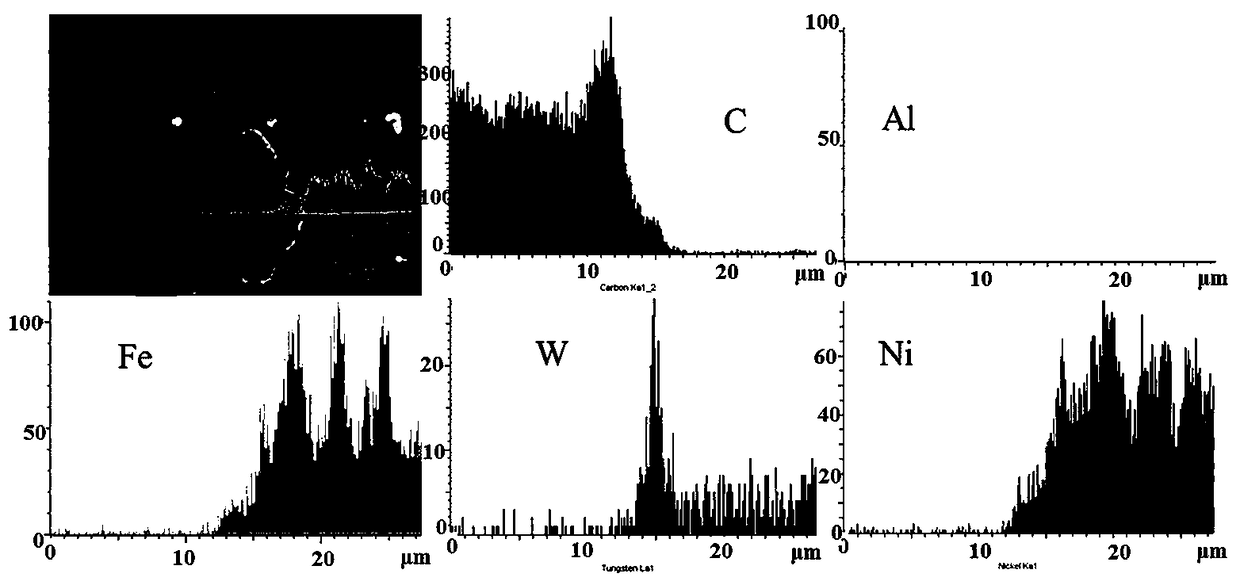

[0033] The invention relates to a low-density heat-resistant iron-based alloy and a preparation method thereof, in particular to a preparation method of a low-density heat-resistant NiAl / diamond reinforced Fe-based alloy. In the process of using Ni powder and Al powder mechanical alloy, a reaction occurs to generate nanometers. For NiAl powder particles with B2 ordered structure, the diamond is pretreated by a suitable process to form a uniform tungsten coating on the surface, and then NiAl powder and pretreated diamond powder are filled into the ball mill jar, and the The Fe powder is continuously mixed uniformly to obtain fine and uniform NiAl / diamond reinforced Fe-based alloy composite powder, and then a bulk composite material is obtained by hot pressing sintering to obtain a low-density heat-resistant NiAl / diamond reinforced Fe-based material. Include the following steps:

[0034] Step 1: According to the mass ratio of material: grinding ball = 1:10, the raw material powd...

Embodiment 1

[0043] Put Ni powder (20.55g) and Al powder (9.45g) into the zirconia ball mill according to the atomic ratio of raw materials 1:1, add 300g of zirconia grinding balls with a diameter of 10mm, and seal with O type before ball milling After ring sealing, vacuum the ball mill tank and fill it with argon gas, carry out ball milling at a speed of 250r / min, run / stop interval time of 30min, and carry out mixed ball milling under the condition of a total of 70h, to obtain fine and uniform nano-NiAl powder with B2 structure. .

[0044] According to the mass ratio of 75%: 20%: 5%, the synthetic diamond powder (75.00g), copper powder (20.00g) and tungsten powder (5.00g) were mixed and pretreated according to the following process: pickling (hydrochloric acid concentration 10 % (mass percentage), cleaning at 60°C for 30 minutes) → ultrasonic cleaning in absolute ethanol for 20 minutes → ultrasonic cleaning in acetone for 20 minutes → ultrasonic cleaning in absolute ethanol for 20 minutes...

Embodiment 2

[0046] According to the mass fraction of raw materials: 50.00% Fe powder (50.00g) and 50.00% NiAl (50.00g) powder obtained in Example 1 were put into a stainless steel ball mill. Mixing in a ball mill with a rotational speed of 100 r / min for 5 h to obtain the final alloy powder.

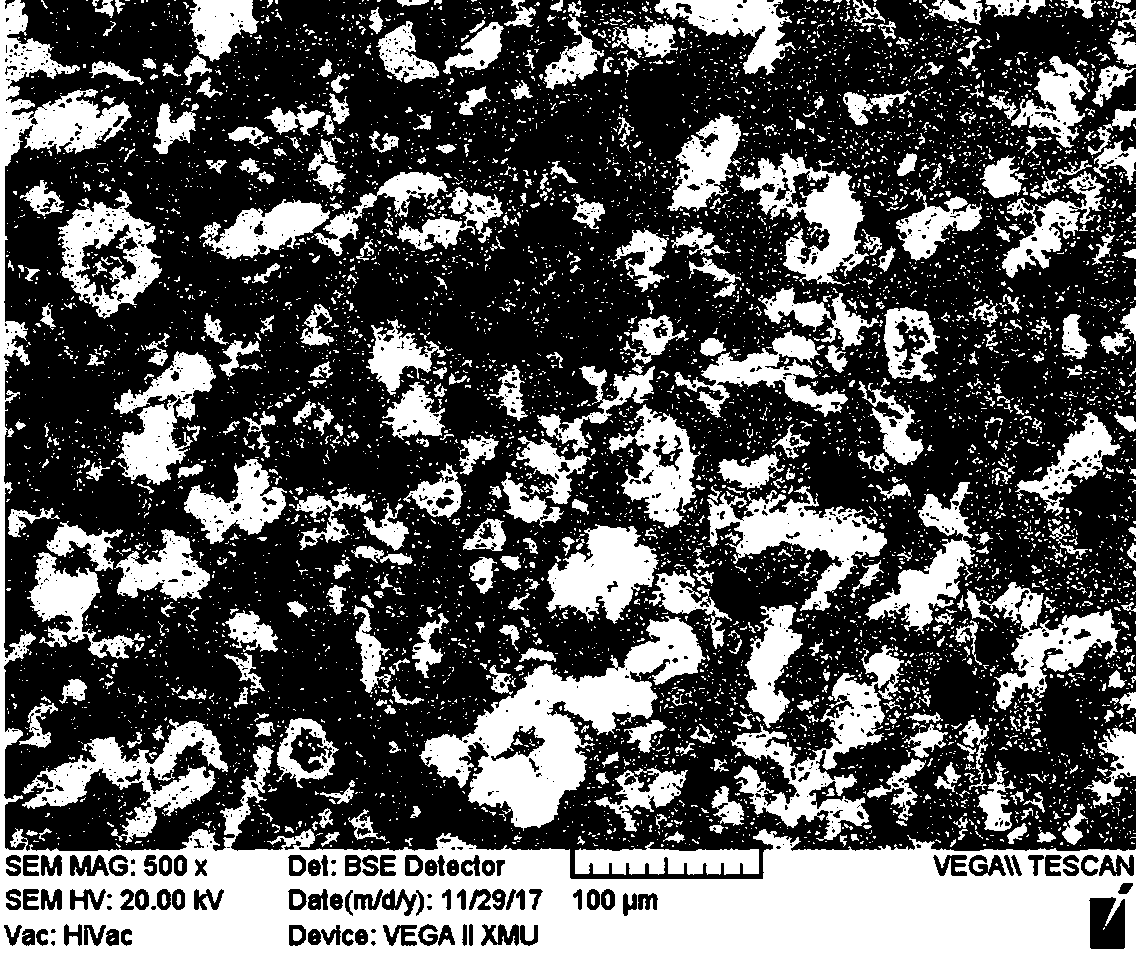

[0047] Weigh 30 g of the mixture powder prepared in Example 2, put it into a high-strength graphite mold, and sinter it in a hot-pressing sintering furnace (ZT-40-20Y) produced by Shanghai Chenhua Electric Furnace Co., Ltd. The main sintering process parameters are: the degree of vacuum is 6.67×10 -3 Pa, hot-pressing sintering was heated to 1050°C at a heating rate of 10°C / min and held for 60 minutes, and then cooled to room temperature with the furnace to finally obtain a B2-structured nano-NiAl phase reinforced iron-based alloy sintered body with a mass fraction of 50%.

[0048] The sintered body was mechanically cut into a certain size. According to the specific operation of the experimental poli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com