Gold leaching method adopting ferrous ions and magnesium thiosulfate

A technology of magnesium thiosulfate and ferrous ions, applied in the field of leaching gold from magnesium thiosulfate, using ferrous ions, can solve the problems of unfriendly environment, difficult recovery of gold in leaching solution, high consumption of thiosulfate, etc. Competitive adsorption, reduced consumption, and the effect of solving high consumption of thiosulfate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Preparation of magnesium thiosulfate: Add ammonium thiosulfate to magnesium hydroxide in a molar ratio of 1:1 into a beaker, heat to 45°C and keep constant temperature, and remove NH in the solution 3 . After a certain period of time, use a wet red litmus test to test, if the test paper does not turn blue, it means that NH 3 Has been drained to obtain magnesium thiosulfate solution.

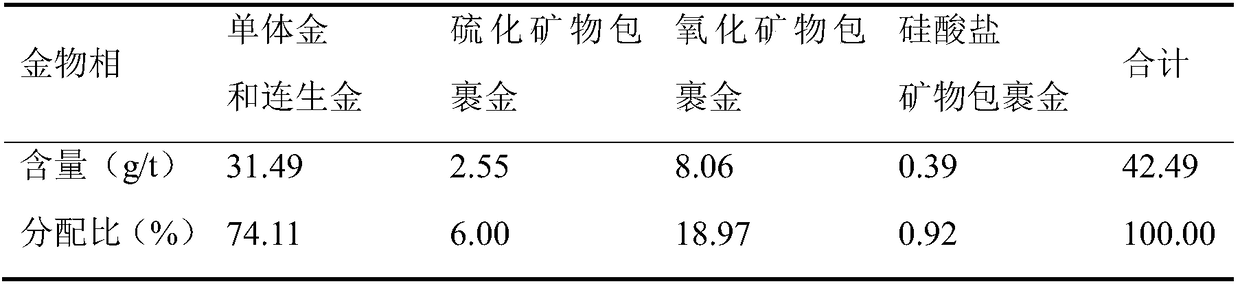

[0030] Raw material condition 1: A flotation gold concentrate, in which the grade of Au is 42.49g / t, and the mass contents of Cu, Fe, Pb, S, As, Sb, and C are respectively 0.20%, 16.93%, 0.19%, and 14.25% , 5.40%, 0.67%, 0.80%. Its mineral composition is mainly pyrite and quartz. Table 1 shows the chemical phase analysis results of gold in the flotation gold concentrate.

[0031] Table 1 Chemical phase analysis results of gold in flotation gold concentrate

[0032]

Embodiment 1

[0036] Using pulp with the same particle size and mass concentration as Comparative Example 1, first add ferrous sulfate to the pulp to a concentration of 0.01mol / L, and then adjust the pH value of the pulp to 8.0 with sodium hydroxide. Then, add magnesium thiosulfate to a concentration of 0.3mol / L, adjust the pH value of the pulp to 10.0 with sodium hydroxide again, and other leaching conditions are the same as in Comparative Example 1, the leaching rate of gold is 72.25%, and the consumption of magnesium thiosulfate The amount is 23.28kg / t raw material. The recovery conditions of gold in the leaching solution are the same as those in Comparative Example 1, but the desorption of the gold-loaded resin adopts a one-stage process, and the recovery rate of gold is 99.2%.

Embodiment 2

[0038] Using the pulp with the same particle size and mass concentration as in Comparative Example 1, first add ferrous sulfate to a concentration of 0.03mol / L, then use sodium hydroxide to adjust the pH value of the pulp to 8.0, and then add magnesium thiosulfate to a concentration of 0.5mol / L, adjust the pH value of the pulp to 10.0 with sodium hydroxide again, and other leaching conditions are the same as those in Comparative Example 1, the gold leaching rate is 73.32%, and the consumption of magnesium thiosulfate is 25.58kg / t raw material. The recovery conditions of gold in the leaching solution are the same as in Implementation 1, and the recovery rate of gold is 98.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com