Method for preparing hafnium oxide based ferroelectric film by adopting reaction magnetron sputtering

A technology of reactive magnetron sputtering and hafnium dioxide, which is applied in sputtering plating, ion implantation plating, coating, etc., can solve the problems of easy cracking, high cost of ceramic targets, and high cooling requirements, and achieve compactness Good, flexible power supply selection, good film uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

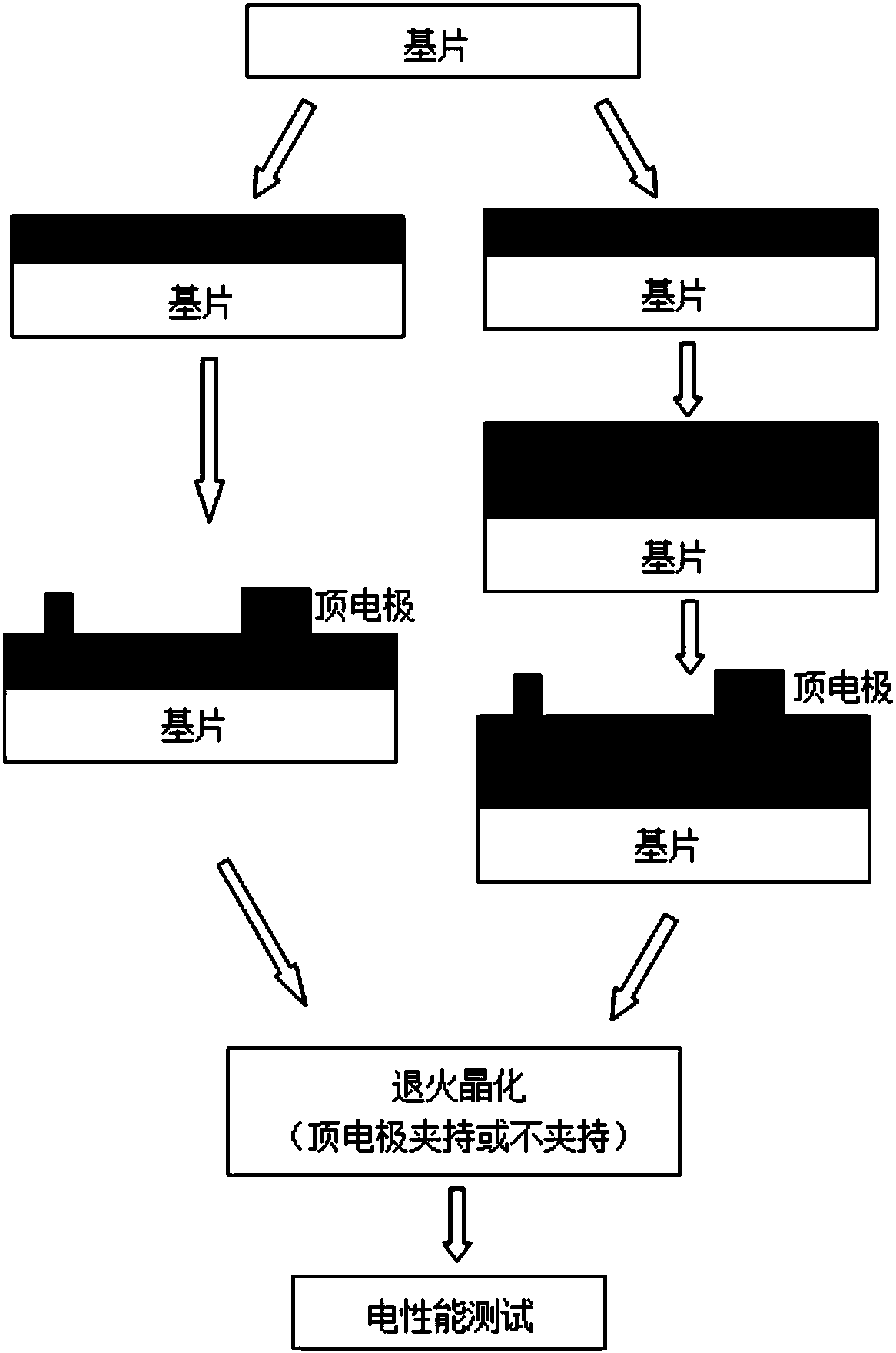

Method used

Image

Examples

Embodiment example 1

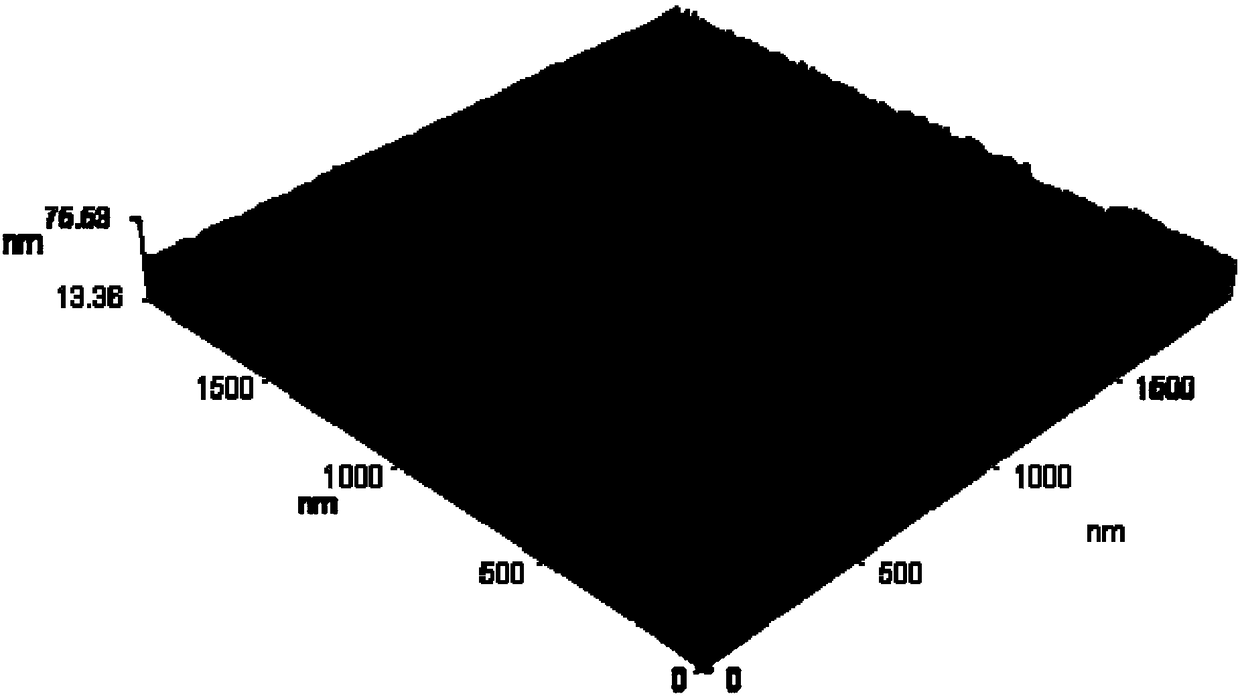

[0025] In this embodiment, a p-Si substrate is selected as the substrate, and the standard RCA cleaning process in the semiconductor industry is used for cleaning. The hafnium target is a face-to-face planar magnetron target with a purity of 99.9%, which is placed perpendicular to the sample stage. The yttrium target is a cylindrical target with a purity of 99.9%, which is placed obliquely above the planar magnetron target. The target base distance is 90mm. Reactive magnetron sputtering, background vacuum up to 5x10 -4 Pa, high-purity argon (99.99%) as the working gas, high-purity oxygen (99.99%) as the reaction gas, Ar:O 2 =10:10sccm, working pressure 0.3Pa, Hf target sputtering power 50W, Y target sputtering power 30W, substrate temperature is room temperature, pre-sputtering time 5min, sputtering time 30min, the Y doping amount obtained is 1mol%, HfYO with a film thickness of 10 nm 2 Amorphous thin film. It is annealed at N 2 Under the atmosphere, the temperature is 600...

Embodiment example 2

[0027] In this embodiment, a p-Si substrate is selected as the substrate, and the standard RCA cleaning process in the semiconductor industry is used for cleaning. The hafnium target is a face-to-face planar magnetron target with a purity of 99.9%, which is placed perpendicular to the sample stage. The silicon target is a cylindrical target with a purity of 99.9%, which is placed obliquely above the planar magnetron target. The target base distance is 120mm. Reactive magnetron sputtering, background vacuum up to 5x10 -4 Pa, high-purity argon (99.99%) as the working gas, high-purity oxygen (99.99%) as the reaction gas, Ar:O 2 =20:20sccm, working pressure 0.5Pa, Hf target sputtering power 80W, Si target sputtering power 50W, substrate temperature 200°C, pre-sputtering time 5min, sputtering time 60min, the Si doping amount is 4mol% , with a film thickness of 20 nm in HfSiO 2 Amorphous thin film. It is annealed at N 2 Under the atmosphere, the temperature is 700°C, the holding...

Embodiment example 3

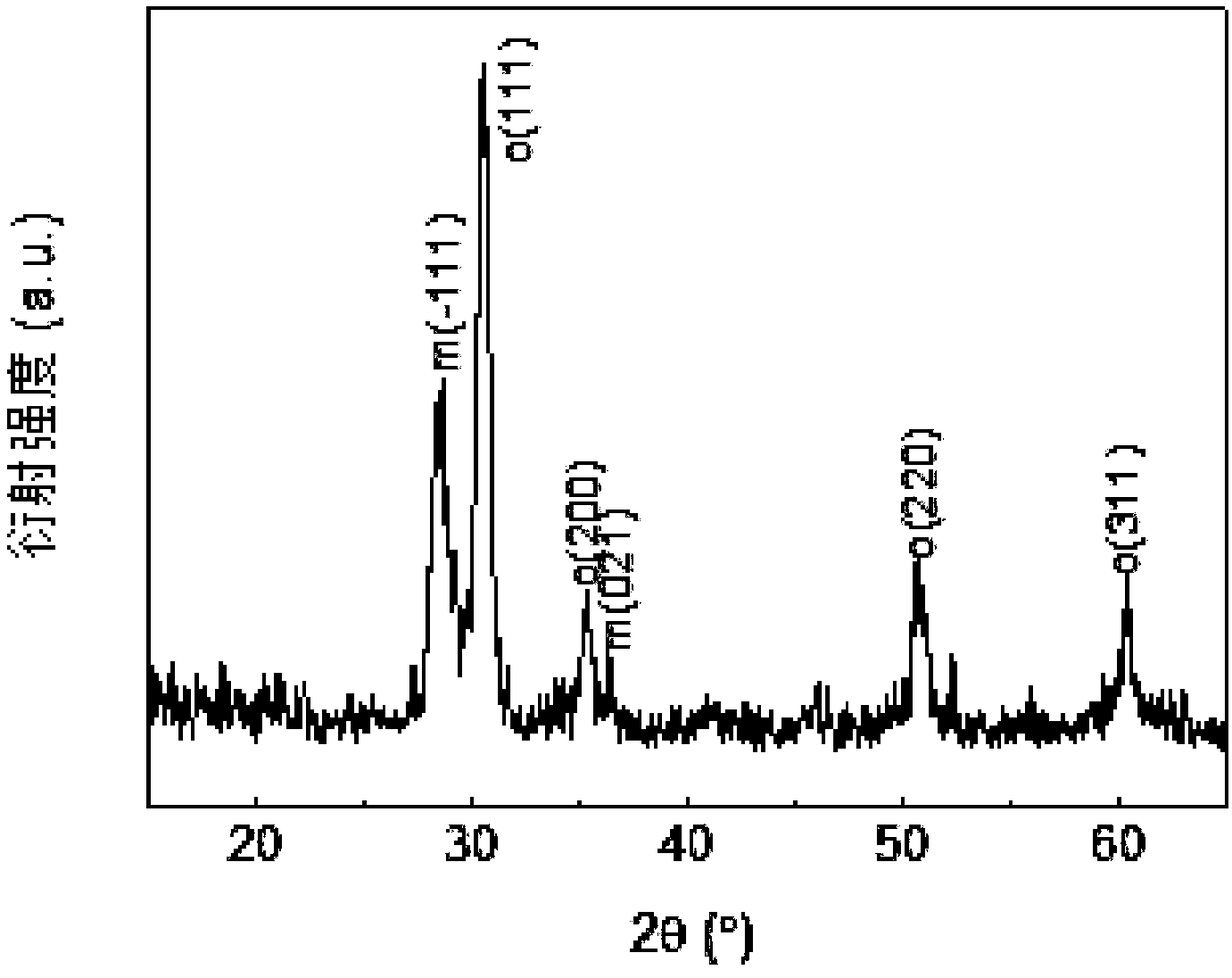

[0029] In this embodiment, a p-Si substrate is selected as the substrate, and the standard RCA cleaning process in the semiconductor industry is used for cleaning. The hafnium target is a face-to-face planar magnetron target with a purity of 99.9%, which is placed perpendicular to the sample stage. The zirconium target is a cylindrical target with a purity of 99.9%, which is placed obliquely above the planar magnetron target. The target base distance is 160mm. Reactive magnetron sputtering, background vacuum up to 5x10 -4 Pa, high-purity argon (99.99%) as the working gas, high-purity oxygen (99.99%) as the reaction gas, Ar:O 2 =40:40sccm, working pressure 0.8Pa, Hf target sputtering power 100W, Zr target sputtering power 120W, substrate temperature 300°C, pre-sputtering time 10min, sputtering time 90min, doping amount 50mol%, thickness 30nm HfZrO 2 Amorphous thin film. It is annealed at N 2 Under the atmosphere, the temperature is 800°C, the holding time is 40s, and the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com