Preparation and application of pynamic polymer containing composite dynamic covalent bonds

A dynamic covalent bond and polymer technology, applied in the field of dynamic polymer materials and polymer materials, can solve problems such as difficult comprehensive performance and limited dynamic performance of dynamic covalent bonds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

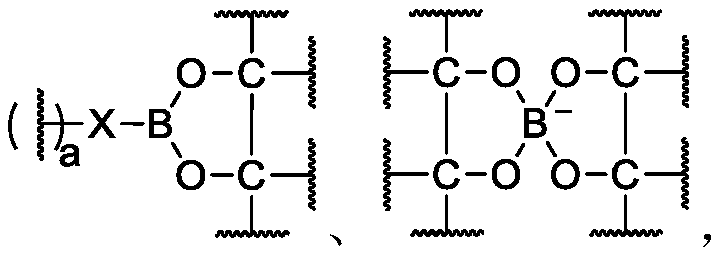

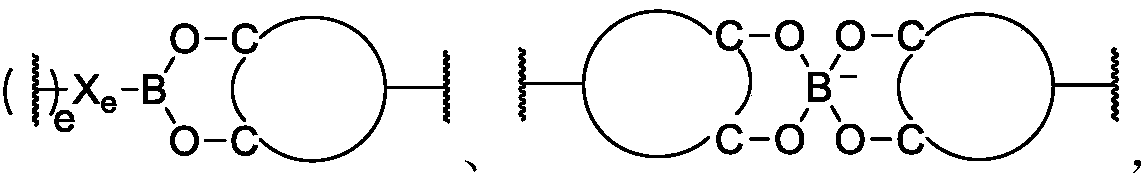

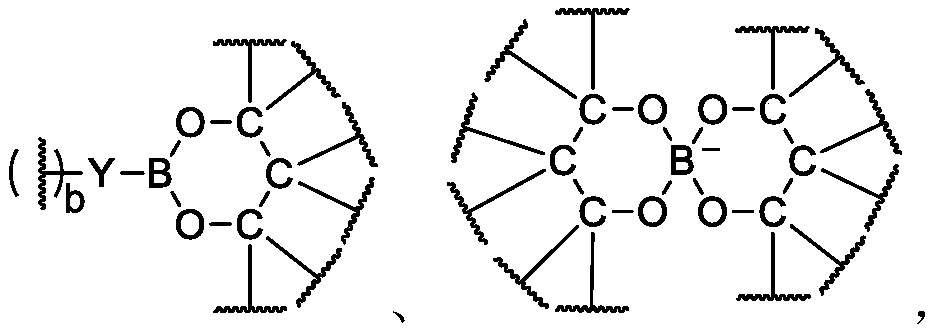

[0466] The invention provides a method for preparing a dynamic polymer containing combined dynamic covalent bonds. The dynamic polymer has a linear or cyclic structure, and it is preferably prepared by at least one of the following methods (but this The invention is not limited thereto):

[0467] The first one is obtained by at least the following components participating in the reaction to generate a dynamic covalent bond: at least one inorganic boron compound (I), at least two hydroxyl-containing compounds (selected from compound (II) to compound (VII), the same below) ); wherein, both the inorganic boron compound (I) and the hydroxyl-containing compound contain at most two functional groups;

[0468] The second type is obtained by at least the following components participating in the reaction to generate dynamic covalent bonds and ordinary covalent bonds: at least one inorganic boron compound (I), at least two hydroxyl-containing compounds; or at least one inorganic boron ...

Embodiment 1

[0571] Add 25g boric acid, 61g 1,1,3,3,5,5,7,7-octamethyl-1,7-tetrasiloxanediol, 32g 3,3'-oxybis (Propane-1,2-diol), 150mL toluene solvent, 2mL deionized water, after heating the reaction solution to boiling, add 2.5mL triethylamine, and continue to stir and react for 2h under boiling conditions. Then add 2.2g sodium dodecylbenzenesulfonate, 0.65g (2-amino-4(18)-pyrimidinone and 1,6-hexamethylene diisocyanate reacted at 100°C), 0.9g bentonite , 0.6g stearic acid, 0.5g oleic acid, then add 2.2g graphene, 0.5g organobentonite, 0.5g polydimethylsiloxane, 0.3g dibutyltin dilaurate, 56mg light stabilizer 770, After ultrasonic dispersion for 40 minutes, continue heating and stirring to mix evenly to obtain a liquid with a certain viscosity. Pour a solution sample with a certain viscosity into a suitable mold, dry the sample in an oven at 80°C for 24 hours to remove the solvent, and then cool it to room temperature for 30 minutes to finally obtain a film-like polymer sample. It was...

Embodiment 2

[0573] In No. 1 reactor, add 25.9 mL of polyol compound (with 4-hydroxystyrene and formaldehyde as raw materials, reflux it with zinc nitrate hexahydrate for 24 hours to synthesize 2-(hydroxymethyl)-4-vinylphenol, and then Using methanol as a solvent and triethylamine as a catalyst, it was prepared by thiol-alkene click addition reaction with pentaerythritol tetramercaptoacetate), 24.5mL of hydroxyl-terminated methylphenyl silicone oil (molecular weight is about 12,000), 20mL of deionized water, 0.5g of carbon nanotubes, 0.2mg of BHT antioxidant, after ultrasonic dispersion for 1 hour, heated to 90°C under stirring; then added 2.57g of metaboric acid, 1.5mL of triethylamine, continued at 90°C After reacting for 60-90 minutes, pour it into a suitable mold, and place the sample in a vacuum oven at 80°C for 24 hours for further reaction, then cool to room temperature and leave it for 30 minutes to finally obtain a block of hard polymer material, polymerized The surface of the obj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com