Recovery system and method of single nickel salt coloring and moderate temperature hole sealing agents in aluminum processing

A recycling system, aluminum processing technology, applied in chemical instruments and methods, nickel carbonate, water/sludge/sewage treatment, etc., can solve problems such as waste of useful resources, high disposal costs, problems in waste water and slag treatment, and reduce The effect of environmental cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

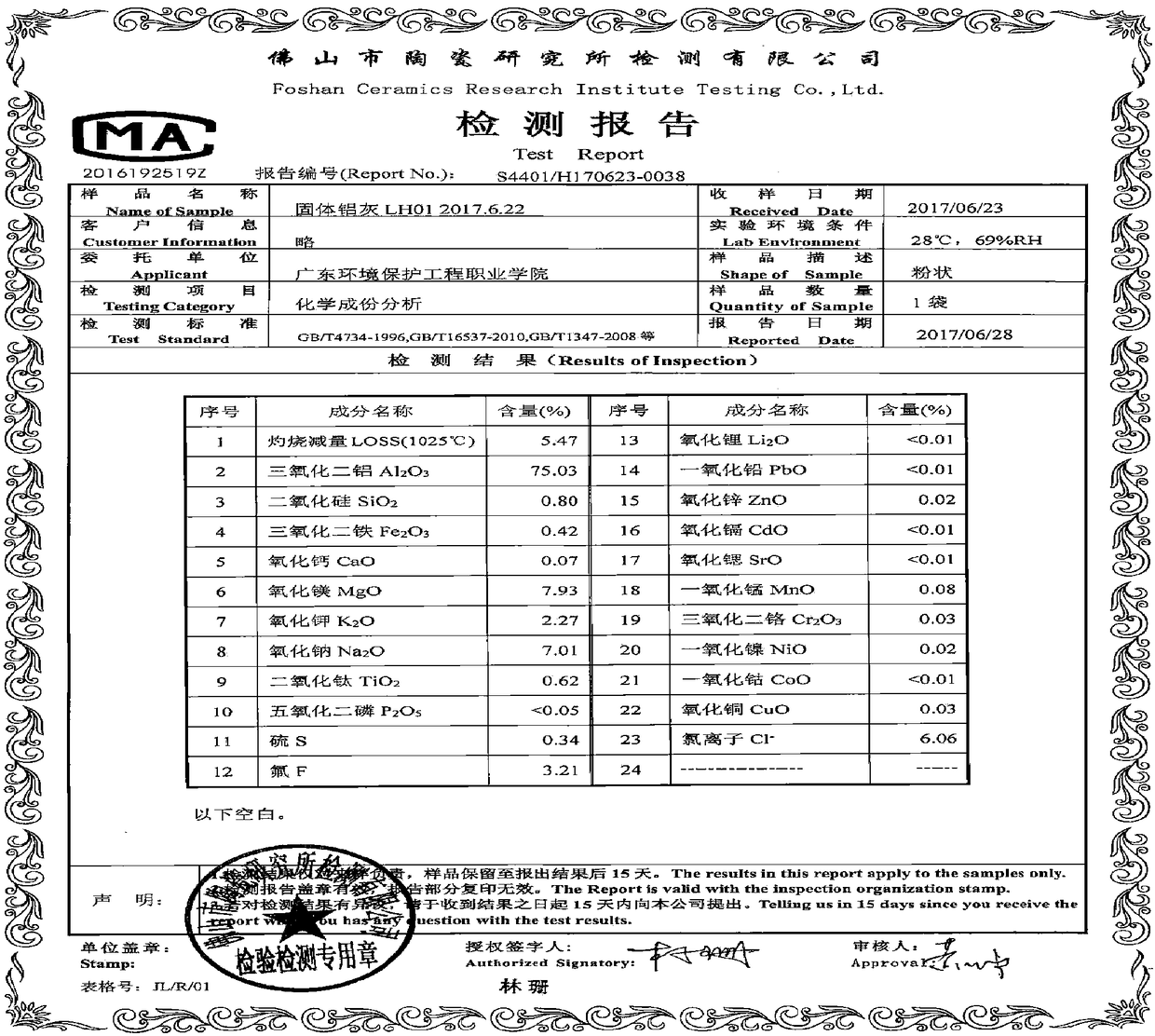

[0233] Embodiment 1 (operation of intercepting nickel-containing waste water)

[0234] Open the 1# valve and 5# valve, the water enters from the 1# valve, and flows through the 2# valve, 3# valve, 4# valve into the 14# flowing water washing tank, and then flows out from the 5# valve, only one cleaning water returns Flow in series; after the aluminum alloy with an oxide film thickness of 15 microns is colored in 13# single nickel salt coloring tank, trickle for 30s; enter 14# flowing water washing tank, 15# flowing water washing tank, wash for 60s, trickle for 30s; enter 16 #Medium temperature sealing tank, sealing for 15min, trickle for 30s; enter 17# flow washing tank, 18# flow washing tank, wash for 60s, trickle for 30s, complete nickel-containing wastewater interception operation;

Embodiment 2

[0235] Embodiment 2 (collect the operation of nickel-containing waste water)

[0236] Open the 6# valve or 7# valve, and flow the wastewater flowing out of the 14# flowing washing tank into the nickel-containing wastewater collection pool A or B to complete the nickel-containing wastewater collection operation;

Embodiment 3

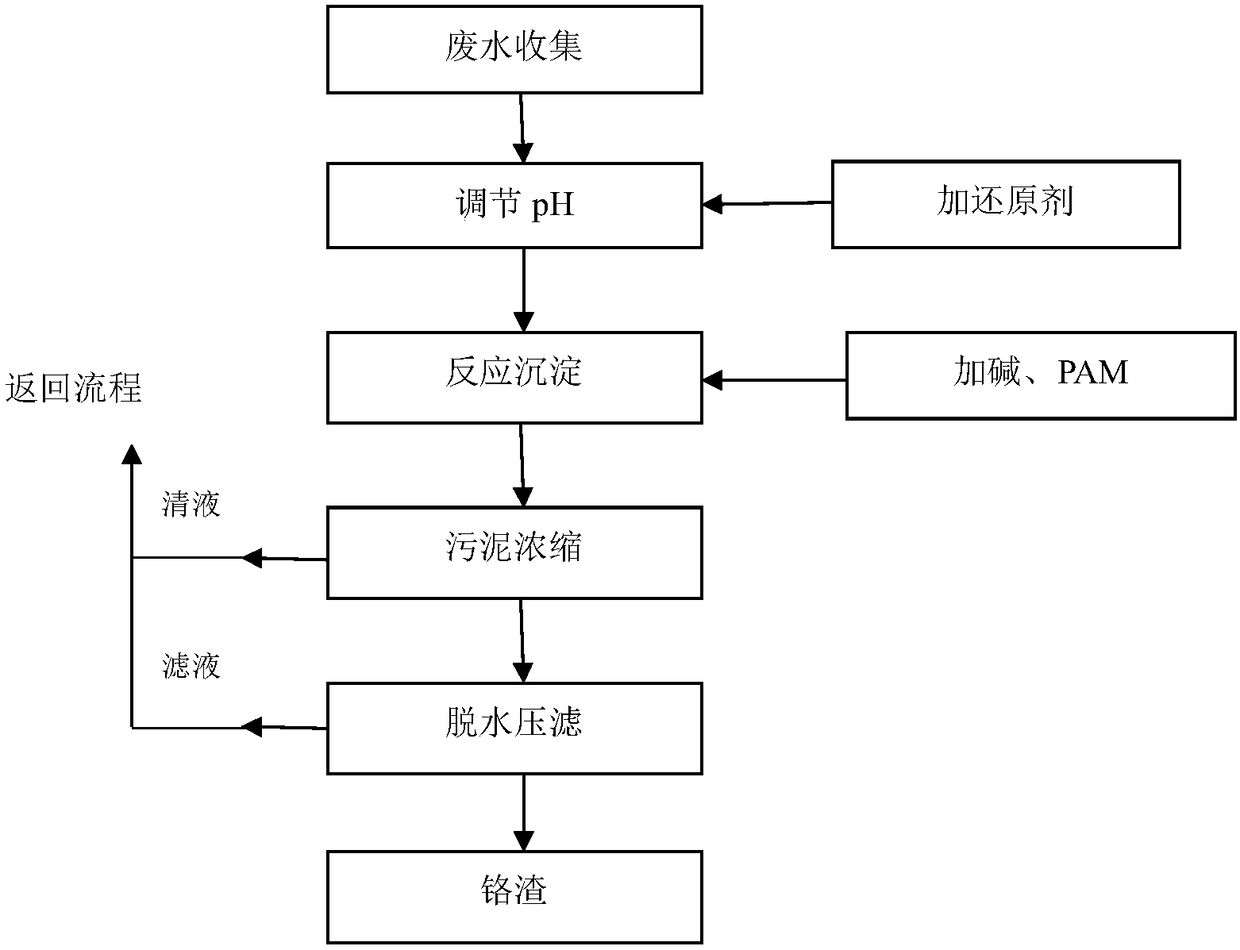

[0237] Embodiment 3 (recover the operation of basic nickel carbonate)

[0238] Open the 8# valve or 9# valve, turn on the No. 1 pump, and open the 10# valve, close the 11# valve, pump the wastewater in the nickel-containing wastewater collection pool A or B into the recovery tank; turn on the 1# electric agitator, and slowly add Sodium carbonate while detecting the pH value, until the pH value is 9.0, stop adding sodium carbonate, continue to stir for 30min, reclaim Ni 2+ , the reaction generates basic nickel carbonate; open the 11# valve, turn on the centrifuge, separate the solid and liquid of the nickel-containing wastewater, recover the solid basic nickel carbonate, and the liquid nickel-containing wastewater flows into the secondary crystallization tank for standby; complete the recovery of basic nickel carbonate operate;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com