A method for extracting and recovering titanium from acid solution

An acid solution and titanium recovery technology, applied in the field of mineral processing engineering, can solve problems such as difficult stripping of titanium, and achieve the effects of complete separation, simple process flow and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

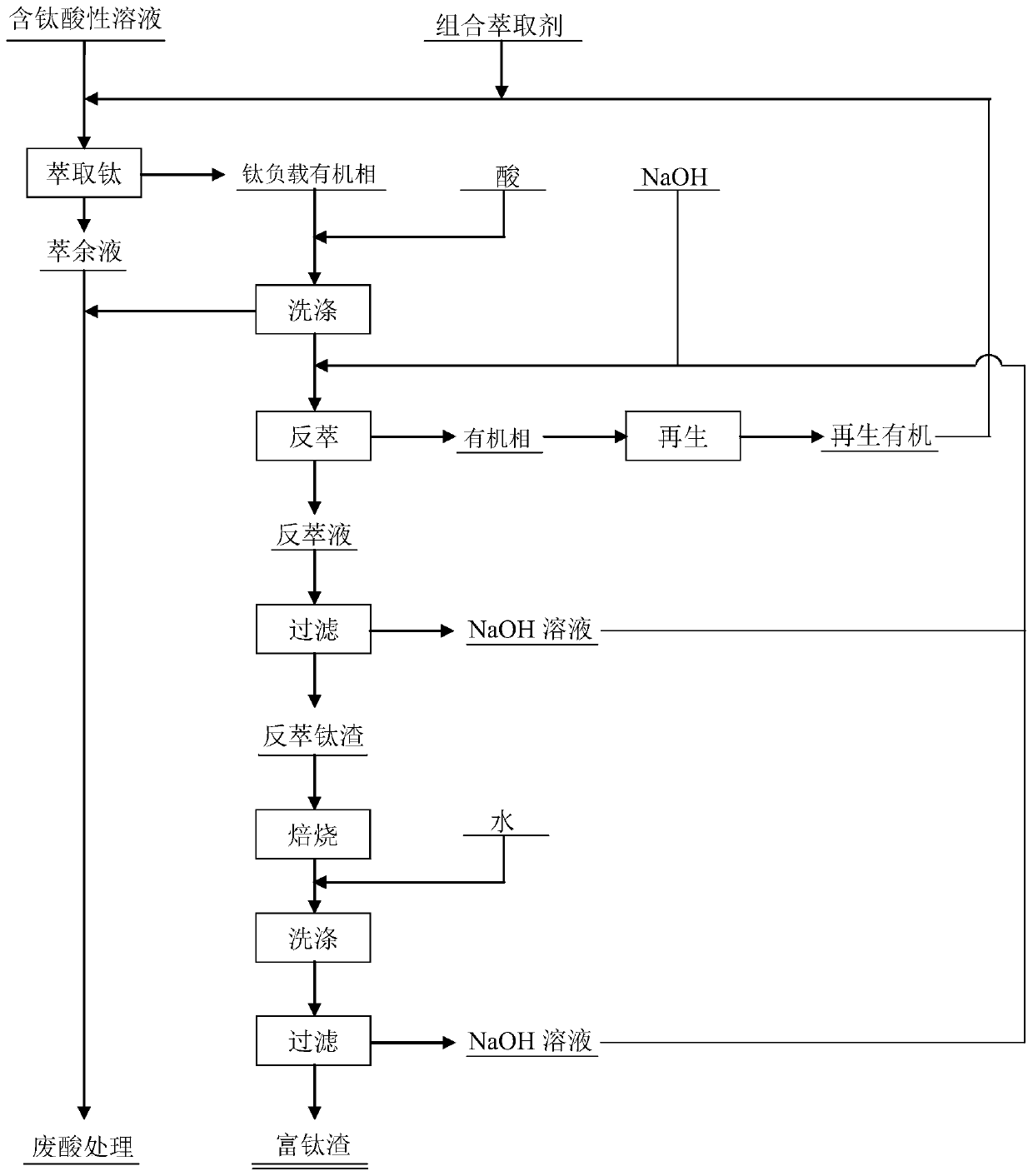

Embodiment 1

[0032] A scandium-rich anatase in Guizhou containing TiO 2 5.00%, including Sc 2 o 3 120 g / t. Titanium is mainly produced in the form of fine-grained anatase wrapped in silicate and quartz, and the particle size is extremely fine. Secondly, it occurs in limonite in the form of isomorphism, which is an extremely difficult ore. Scandium element mainly occurs in clay minerals such as kaolinite and sericite, and secondarily occurs in limonite and anatase. The ore is leached with sulfuric acid in two stages. 2 SO 4 Content 423.9 g / L, containing TiO 2 10.02g / L, Sc 2 o 3 15.92 mg / L, TFe 29.91g / L. Such as figure 1 As shown, titanium is extracted and extracted from the leaching solution. In terms of volume percentage, 15% combined extractant (P204:N1923=2.5:1), 5% 2-octanol, 80% 260 # Kerosene, compared with O / A=2:1, three-stage countercurrent extraction of titanium, the extraction temperature is 10°C, the extraction time is 30min, titanium is selectively extracted from the s...

Embodiment 2

[0034] A titanium dioxide factory in Sichuan has an annual output of 100,000 tons of titanium dioxide and 900,000 tons of titanium dioxide waste acid, which contains TiO 2 7.48 g / L, TFe 31 g / L, H 2 SO 4 386g / L. Such as figure 1 As shown, the extraction and separation of titanium from the titanium dioxide waste acid, by volume percentage, using 20% combined extractant (P507:N235=3:1), 5% 2-octanol, 75% 260 #Kerosene, compared with O / A=1:1, four-stage cross-flow extraction of titanium, the extraction temperature is 20°C, the extraction time is 18min, titanium is selectively extracted from the solution containing titanic acid, and iron, aluminum, Magnesium and other impurity ions are separated to obtain the titanium-loaded organic phase and the titanium raffinate. The titanium-loaded organic phase is washed in two-stage countercurrent with O / A=3:1, 2 mol / L sulfuric acid solution, and then 2 mol / L NaOH solution, compared with O / A=3:1, one-stage stripping of titanium, the ...

Embodiment 3

[0036] Smelting slag of a vanadium-titanium magnetite in Sichuan, containing TiO 2 is 18.00%, and the HCl content of the leachate obtained by hydrochloric acid leaching is 400 g / L, containing TiO 2 16.18g / L, TFe 18.43g / L. Extraction and separation of scandium and titanium from the leachate, by volume percentage, using 20% combined extractant (P204:N1923=3:1), 5% isoamyl alcohol, 75% 260 # Kerosene, compared to O / A=2:1, three-stage countercurrent extraction of titanium, the extraction temperature is 30 ° C, the extraction time is 5 minutes, titanium is selectively extracted from the solution containing titanic acid, and iron, aluminum, and magnesium in the acid solution Separation of impurity ions, etc., to obtain titanium-loaded organic phase and titanium raffinate, using O / A=2:1, 3mol / L hydrochloric acid solution for three-stage countercurrent washing of titanium-loaded organic phase, and then using 3 mol / L NaOH solution, compared to O / A=2:1, one-stage back-extraction of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com