Clearing device for removing PTFE seal tape on angle valve

A technology of removing device and raw material belt, which is applied in the direction of using tools for cleaning, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of low cleaning efficiency, manual removal by manpower, time-consuming and laborious, and save labor costs. , high cleaning efficiency, simple setting and operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, so that those skilled in the art can implement it with reference to the description.

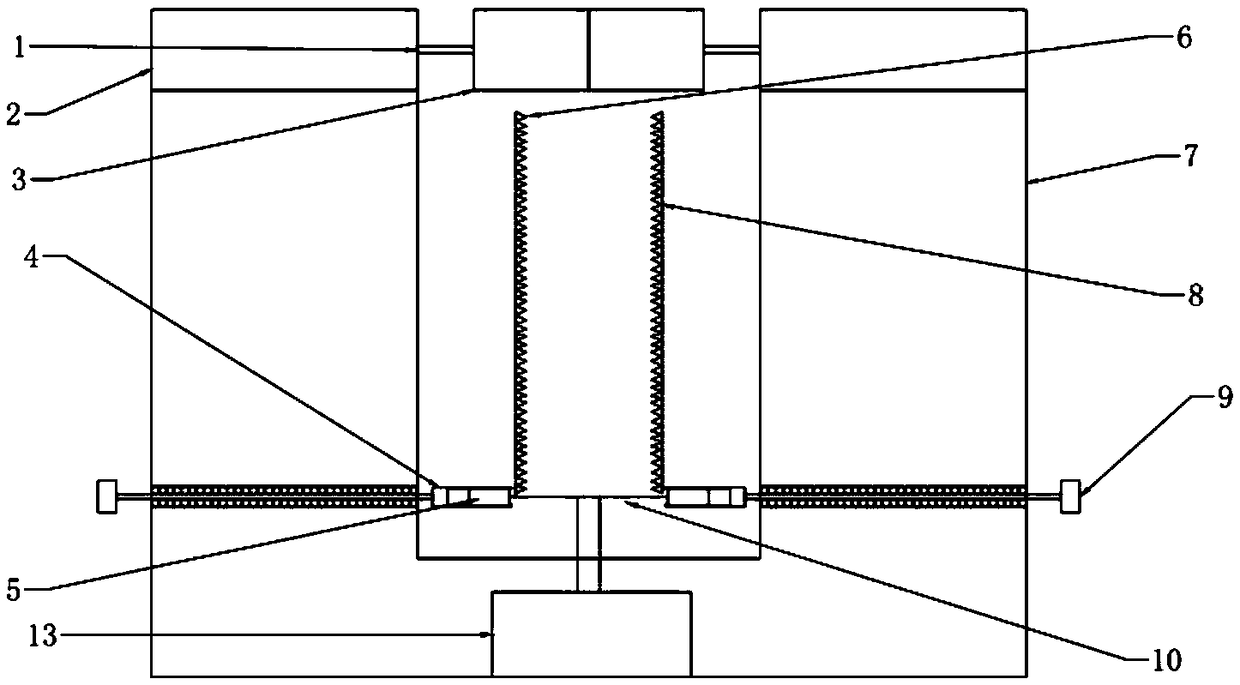

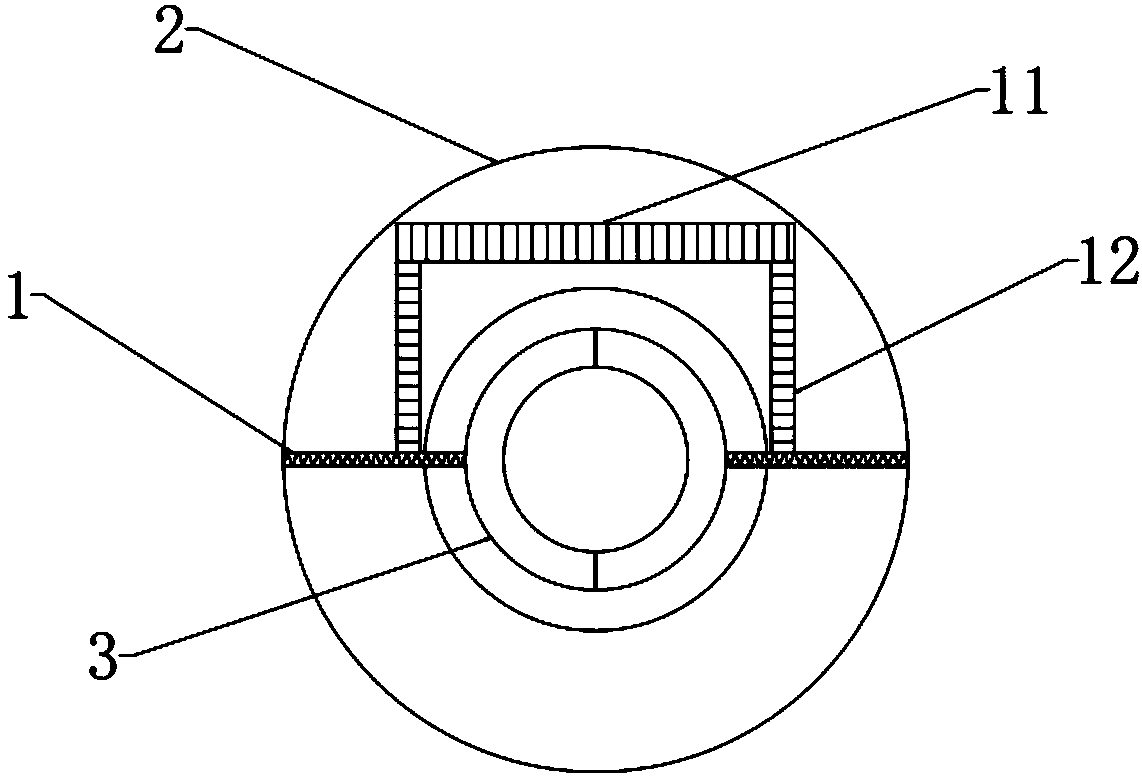

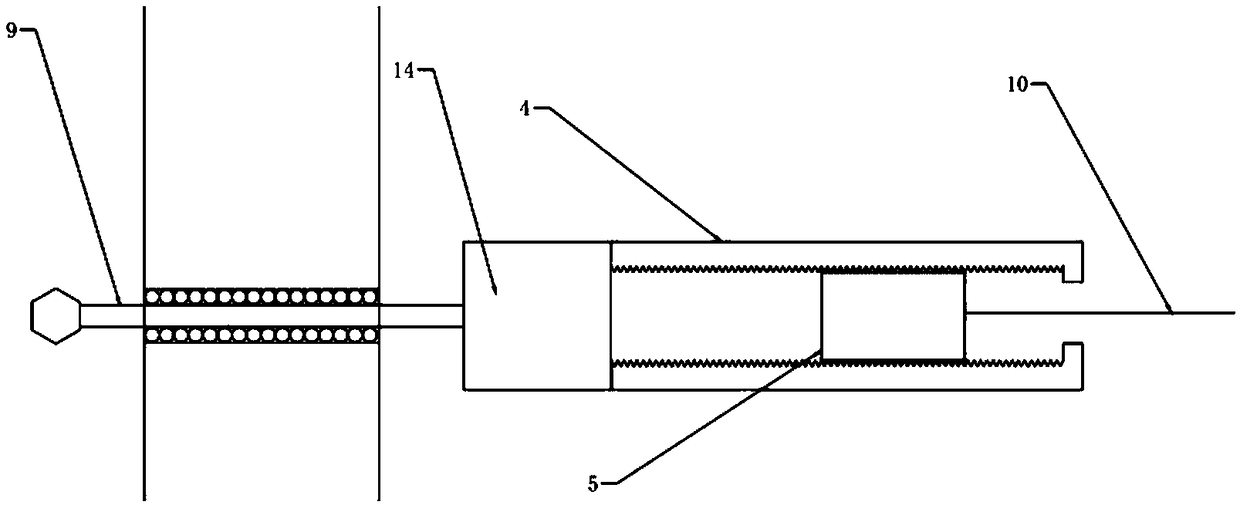

[0026] Such as Figure 1~3 As shown, the invention provides a kind of clearing device for removing the raw material belt on the angle valve, comprising:

[0027] Clean bucket 7, its top is open, the bottom is closed, is provided with motor 13 in clean bucket 7, and the output shaft of motor 13 is arranged vertically upwards, and the thickness of the barrel wall of clean bucket 7 is at least 10cm, and the cylinder wall of clean bucket 7 is vertical Four first through holes are arranged in its axial direction, and the four first through holes are on the same horizontal plane. A bearing with the same length as the first through hole is arranged in each first through hole. The ring is fixedly sleeved with a hexagonal positioning cylinder along its axial direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com