Dual-phase in-situ nano-enhanced ti-based composite material and preparing method thereof

A titanium-based composite material, nano-reinforced technology, applied in the direction of additive processing, additive manufacturing, process efficiency improvement, etc., can solve the problems of easy pollution, reduced wettability, large energy consumption, etc., to achieve enhanced dislocation strengthening effect, enhanced fine-grain strengthening effect, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

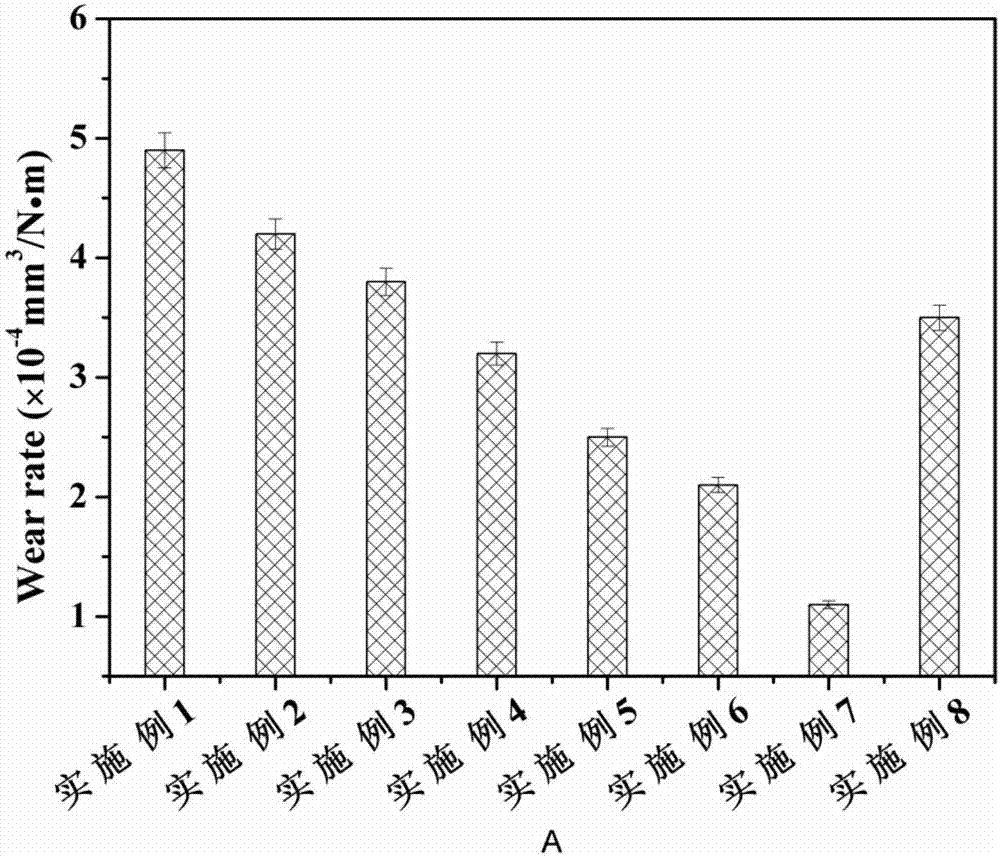

Examples

Embodiment 1

[0026] Step (1): According to the mass ratio of spherical AlSi12 alloy powder and pure titanium powder dedicated to laser 3D printing to 1:99, weigh them respectively, wherein the particle size of the spherical pure titanium powder is 15-53 μm, the purity is 99.7%, and the particle size of the spherical AlSi12 alloy powder is The diameter is 10-30 μm, and the purity is 99.7%. Under the protection environment of high-purity argon gas with a purity of 99.99%, the high-energy ball milling process is used at a speed of 200rpm. Forward rotation ball milling for 10 minutes, intermittent air cooling for 5 minutes, followed by reverse ball milling for 10 minutes, 5 cycles of alternating cycles, ball milling and mixing the spherical powder and then drying to obtain a uniformly mixed composite material forming powder;

[0027]Step (2): Place the uniformly mixed dry pure titanium-AlSi12 alloy composite material forming powder in the step (1) in the powder cylinder of the laser selective m...

Embodiment 2

[0029] Different from Example 1, in this example, the titanium alloy is set as Ti in step (1) 6 Al 4 V, the mass ratio of spherical AlSi12 alloy powder to pure titanium powder is set to 1:54, the ball mill speed is set to 300rpm, and the energy density in step (2) is set to 200J / m 3 , other parameters are the same as in Example 1.

Embodiment 3

[0031] Different from embodiment 2, in this embodiment, the titanium alloy is set as Ti in step (1) 2 Al 1.5 Mn alloy, ball mill speed is set to 200rpm, the laser body energy density is set to 120J / m in step (2) 3 . Other parameters are identical with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com