High-voltage DC cable material containing high-dispersion fullerene and preparation method of high-voltage DC cable material

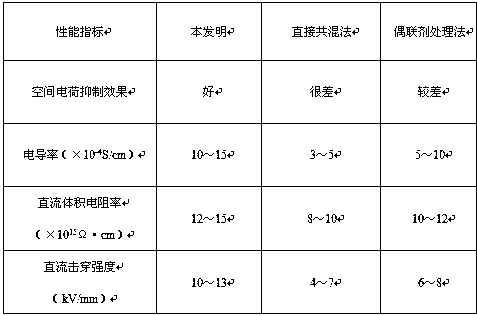

A high-voltage direct current, fullerene technology, applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of affecting the mechanical and electrical properties of cables, weak space charge suppression ability, and inability to effectively disperse, etc., to achieve Improving DC volume resistivity and DC breakdown strength, inhibiting the accumulation of space charges, and facilitating industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

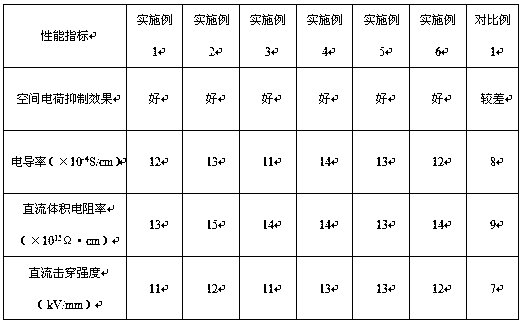

Embodiment 1

[0039] The parts by weight of the raw material components of the high-voltage DC cable material are:

[0040]4 parts of fullerene doped with aluminum foam, 2 parts of polyvinyl chloride powder, 76 parts of thermoplastic polyurethane elastomer, 10 parts of calcium carbonate, 3 parts of flame retardant, 4 parts of plasticizer, 1 part of anti-aging agent; thermoplastic polyurethane elastomer The body is polyester type, the hard segment content is 70%, and the isocyanate index is 0.9; the flame retardant is disodium hydrogen phosphate; the plasticizer is diethyl phthalate; the anti-aging agent is N-phenyl-α-aniline ;

[0041] The preparation process of high voltage DC cable material is as follows:

[0042] (1) Mix acetylene carbon black and foamed aluminum evenly, spread it on the ceramic sheet in the reaction chamber, evacuate the reaction chamber, slowly inject argon gas, turn on the microwave generator, cool to room temperature after 60 minutes of reaction, and stop the introd...

Embodiment 2

[0047] The parts by weight of the raw material components of the high-voltage DC cable material are:

[0048] 3 parts of fullerene doped with aluminum foam, 2 parts of polyvinyl chloride powder, 81 parts of thermoplastic polyurethane elastomer, 8 parts of calcium carbonate, 2 parts of flame retardant, 3 parts of plasticizer, 1 part of anti-aging agent; thermoplastic polyurethane elastomer The body is polyester type, the hard segment content is 60%, and the isocyanate index is 0.85; the flame retardant is lithium phosphate; the plasticizer is dioctyl terephthalate; the anti-aging agent is N-phenyl-β-naphthylamine;

[0049] The preparation process of high voltage DC cable material is as follows:

[0050] (1) Mix acetylene carbon black and foamed aluminum evenly, spread it on the ceramic sheet in the reaction chamber, evacuate the reaction chamber, slowly inject argon gas, turn on the microwave generator, cool to room temperature after reacting for 50 minutes, and stop feeding A...

Embodiment 3

[0055] The parts by weight of the raw material components of the high-voltage DC cable material are:

[0056] 5 parts of fullerene doped with aluminum foam, 3 parts of polyvinyl chloride powder, 69 parts of thermoplastic polyurethane elastomer, 13 parts of calcium carbonate, 4 parts of flame retardant, 5 parts of plasticizer, 1 part of anti-aging agent; thermoplastic polyurethane elastomer The body is polyester type, the hard segment content is 80%, and the isocyanate index is 1; the flame retardant is magnesium phosphate; the plasticizer is dioctyl adipate; the antiaging agent is p-phenylenediamine;

[0057] The preparation process of high voltage DC cable material is as follows:

[0058] (1) Mix acetylene carbon black and foamed aluminum evenly, spread it on the ceramic sheet in the reaction chamber, evacuate the reaction chamber, slowly inject argon gas, turn on the microwave generator, cool to room temperature after 570 minutes of reaction, and stop the introduction argon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com