A high and low temperature resistant ppr pipe with aluminum metal effect

A technology of high and low temperature resistance, aluminum metal, applied in the field of PPR pipe preparation, can solve the problems of single visual effect, poor heat resistance, poor low temperature toughness of PPR pipes, etc., achieve low heat resistance temperature, ensure molding stability, aluminum Consistent effects with metal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

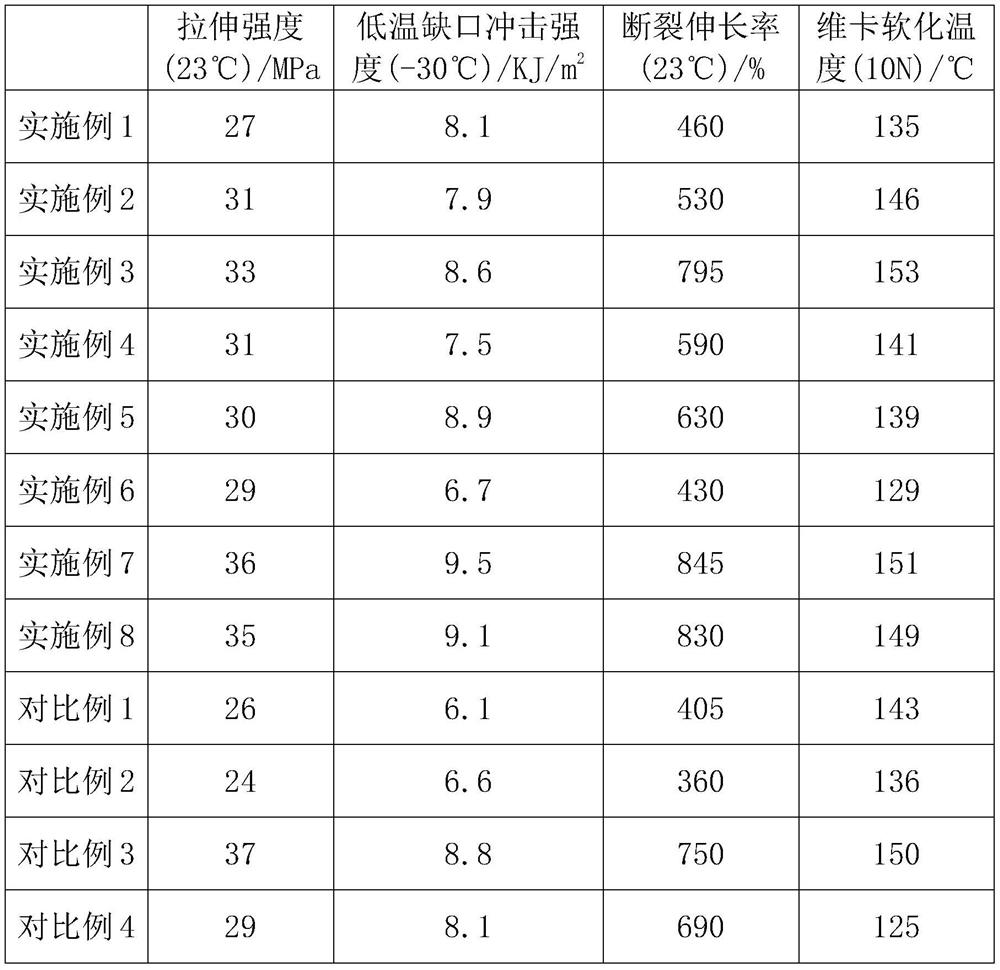

Examples

Embodiment 1

[0034] This embodiment provides a high and low temperature resistant PPR pipe with aluminum metal effect, which contains the following components by weight: 100 parts of PPR, 15 parts of 400 mesh aluminum powder, 8 parts of dispersant, soft core and hard shell type core-shell copolymer 3 parts, 100 mesh styrene-butadiene rubber 10 parts, carbon fiber 5 parts, acicular wollastonite fiber 8 parts, coupling agent 2 parts, antioxidant 1.5 parts.

[0035] In this embodiment, the dispersant is dodecanoic acid, the soft-core hard-shell core-shell copolymer is methyl methacrylate-butyl acrylate core-shell copolymer, and the carbon fibers are polyacrylonitrile-based Carbon fiber, the average aspect ratio of the polyacrylonitrile-based carbon fiber is 100, the average aspect ratio of the acicular wollastonite fiber is 15, and the coupling agent is γ-(2,3-glycidyloxypropoxy ) propyltrimethoxysilane, and the antioxidant is β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate and thi...

Embodiment 2

[0044] This embodiment provides a high and low temperature resistant PPR pipe with aluminum metal effect, which contains the following components by weight: 100 parts of PPR, 10 parts of 800 mesh aluminum powder, 10 parts of dispersant, soft core and hard shell type core-shell copolymer 5 parts of compound, 5 parts of styrene-butadiene rubber, 8 parts of carbon fiber, 3 parts of acicular wollastonite fiber, 1 part of coupling agent, and 2 parts of antioxidant.

[0045] In this embodiment, the dispersant is palmitic acid, the soft-core hard-shell core-shell copolymer is methyl methacrylate-butadiene-styrene core-shell copolymer, and the carbon fiber is pitch-based Carbon fiber, the average aspect ratio of the pitch-based carbon fiber is 130, the average aspect ratio of the acicular wollastonite fiber is 18, the coupling agent is γ-mercaptopropyltrimethoxysilane, the anti The oxygen agent is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol and pentaerythr...

Embodiment 3

[0054] This embodiment provides a high and low temperature resistant PPR pipe with aluminum metal effect, which contains the following components by weight: 100 parts of PPR, 20 parts of 500 mesh aluminum powder, 15 parts of dispersant, soft core and hard shell type core-shell copolymer 8 parts of compound, 8 parts of styrene-butadiene rubber, 10 parts of carbon fiber, 5 parts of acicular wollastonite fiber, 1.5 parts of coupling agent, and 2 parts of antioxidant.

[0055] In this embodiment, the dispersant is stearic acid, the soft-core hard-shell core-shell copolymer is methyl methacrylate-butyl acrylate core-shell copolymer, and the carbon fiber is viscose-based carbon fiber, The average aspect ratio of the viscose-based carbon fiber is 150, the average aspect ratio of the acicular wollastonite fiber is 20, and the coupling agent is tris(dioctylpyrophosphoryloxy)isotitanate Propyl ester, and the antioxidant is 4,6-tris(3,5-di-tert-butyl-4-hydroxybenzyl)benzene and dioctadec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com