Welding method of nickel-based material pipeline

A welding method and pipeline technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., to achieve good weld formation, avoid embrittlement, and improve welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0109] Embodiment 1, a welding method of a nickel-based material pipeline of the present invention, comprising:

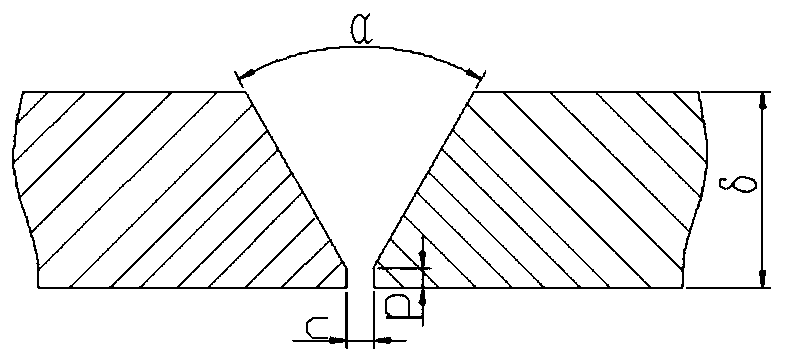

[0110] Step 1. Cold cut the pipe and process the bevel, then polish and clean both sides of the bevel with solvent;

[0111] Step 2. Place the welding workpiece on the modified tooling;

[0112] Step 3, replace the air in the pipeline with argon, and perform tack welding;

[0113] Step 4. When welding, argon tungsten arc welding is used for bottom welding, and manual arc welding is used for filling and covering.

[0114] In another embodiment, in the fourth step, when welding, ERNiCr-3 is used as the welding wire, ENiCrFe-1 is used as the welding rod, and the baking temperature of the welding rod is 200°C.

[0115] In the first step, the slope deviation of the groove is not greater than 1% of the outer diameter of the pipe.

[0116] In another embodiment, the solvent includes acetone or alcohol.

[0117] In another embodiment, the direct current connection meth...

Embodiment 2

[0128] Step 1. Cold cut the pipe and process the bevel, then polish and clean both sides of the bevel with solvent;

[0129] Step 2. Place the welding workpiece on the modified tooling;

[0130] Step 3, replace the air in the pipeline with argon, and perform tack welding;

[0131] Step 4. When welding, argon tungsten arc welding is used for bottom welding, and manual arc welding is used for filling and covering.

[0132] In another embodiment, in the step 4, during welding, ERNiCr-3 is used as welding wire, and ENiCrFe-1 is used as welding rod;

[0133] Rod baking temperature 250°C

[0134] In the first step, the slope deviation of the groove is not greater than 1% of the outer diameter of the pipe.

[0135] The solvent includes acetone or alcohol.

[0136] The bottom welding adopts the direct current connection method, selects the tungsten electrode of Φ2.4mm, the protruding length of the tungsten electrode is 5mm, and the diameter of the nozzle is 12mm.

[0137] The con...

Embodiment 3

[0147] Step 1. Cold cut the pipe and process the bevel, then polish and clean both sides of the bevel with solvent;

[0148] Step 2. Place the welding workpiece on the modified tooling;

[0149] Step 3, replace the air in the pipeline with argon, and perform tack welding;

[0150] Step 4. When welding, argon tungsten arc welding is used for bottom welding, and manual arc welding is used for filling and covering.

[0151] In another embodiment, in the step 4, during welding, ERNiCr-3 is used as welding wire, and ENiCrFe-1 is used as welding rod;

[0152] Rod baking temperature is 225°C

[0153] In the first step, the slope deviation of the groove is not greater than 1% of the outer diameter of the pipe.

[0154] The solvent includes acetone or alcohol.

[0155] The bottom welding adopts the direct current connection method, selects the tungsten electrode of Φ2.4mm, the protruding length of the tungsten electrode is 4mm, and the diameter of the nozzle is 12mm.

[0156] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com