Method for improving charge accumulation in GaN HEMT (High Electron Mobility Transistor) surface electron beam direct writing

A technology of charge accumulation and electron beam, applied in the direction of circuits, electrical components, semiconductor devices, etc., to achieve good adhesion, improve charge accumulation, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

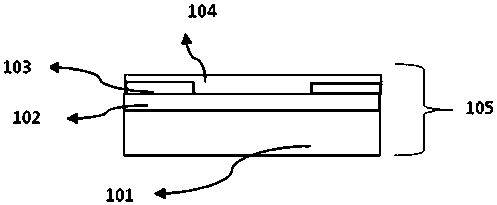

[0028] (1) Preparation of components: On the GaN HEMT epitaxial material, use photolithography to obtain source and drain patterns; prepare source and drain metal systems by electron beam evaporation, stripping and alloying; use enhanced plasma chemical vapor deposition or coupled inductance chemistry A layer of protective dielectric SiN is prepared by vapor deposition method, and the thickness of the SiN is 40nm~200nm; the resistance metal and the capacitor bottom electrode metal are sequentially prepared by ultraviolet lithography, evaporation and sputtering processes;

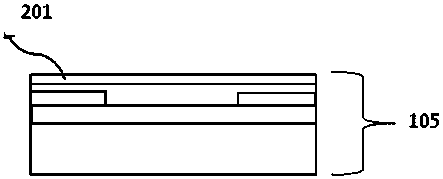

[0029] (2) Preparation of nano-thin metal germanium: nano-thin metal germanium is prepared by electron beam evaporation process or sputtering process, with a thickness of 0~10nm;

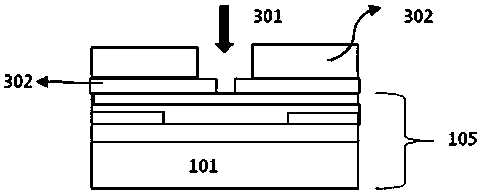

[0030] (3) Electron beam direct writing grid: the preparation of the grid adopts the electron beam direct writing process. The prepared grid is a T-shaped grid or a Y-shaped grid. The grid metal is coated with no less than 2 layers...

Embodiment 1

[0042] A method for improving the charge accumulation of GaN HEMT surface electron beam direct writing, comprising the following steps:

[0043] 1) On the HEMT epitaxial material of the GaN substrate, the source-drain pattern is obtained by photolithography, and then the source-drain metal system is prepared by electron beam evaporation, stripping and alloying, and then a layer of protective dielectric SiN is grown. SiN can be enhanced Prepared by plasma chemical vapor deposition, the thickness is 40nm. Then, resistive metal and capacitor lower electrode metal are sequentially prepared by ultraviolet lithography, evaporation or sputtering and other processes;

[0044] 2) A layer of 5nm-thick metal germanium was prepared by electron beam evaporation process. Then apply electron beam glue, bake, and direct write. Among them, the preparation of GaN small gate length adopts the method of electron beam one-time forming, which needs to apply multiple layers of glue and direct write...

Embodiment 2

[0050] 1) On the HEMT epitaxial material of the GaN substrate, the source-drain pattern is obtained by photolithography, and then the source-drain metal system is prepared by electron beam evaporation, stripping and alloying processes, and then a layer of protective dielectric SiN is grown. SiN can use coupled inductors Prepared by chemical vapor deposition method, the thickness is 200nm. Then, resistive metal and capacitor lower electrode metal are sequentially prepared by ultraviolet lithography, evaporation or sputtering and other processes;

[0051] 2) Prepare a layer of 10nm-thick metal germanium by electron beam sputtering process. Then apply electron beam glue, bake, and direct write. The preparation of GaN small gate length generally adopts the method of electron beam one-time forming, which needs to apply multiple layers of glue and direct write multiple times. Both have the function of eliminating charge accumulation;

[0052] 3) The developed sample is corroded an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com