A kind of preparation method of isocyanate-based polyimide rigid foam

An ester-based polyimide and rigid foam technology is applied in the fields of polymer foam materials and high-performance materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

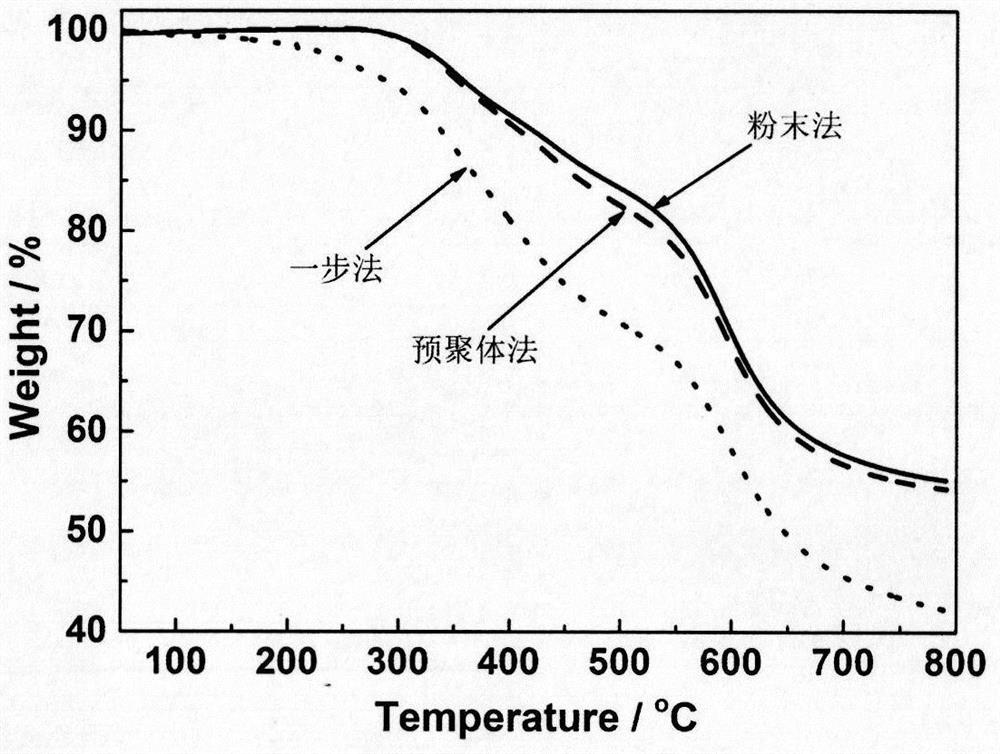

Method used

Image

Examples

Embodiment 1

[0025] Add 100g of pyromellitic anhydride (PMDA) and 25g of methanol into 100g of N,N-dimethylformamide (DMF) and react until clarification at a certain temperature, and then gradually increase the temperature. During the temperature rise to 80°C, add 130g polyphenyl polymethylene polyisocyanate (PAPI), then add 2g stannous octoate catalyst, react at 80-95°C for 3-7 hours to obtain prepolymer solution and cool to room temperature, add 40g PAPI and Stir 2g of triethylamine (TEA) evenly, then add 30g of foam stabilizer AK-8805 and 15g of deionized water, stir at a high speed of 1000-2000r / min for 10-20s and freely foam to obtain a foam intermediate, and finally The foam intermediate is placed in a vacuum drying oven and treated at a high temperature of 160-220°C for 4-6 hours, so that the foam intermediate is fully imidized to obtain a polyimide rigid foam.

Embodiment 2

[0027] Add 100g PMDA and 25g methanol into 100g DMF and react at a certain temperature until clarification, and then gradually increase the temperature. When the temperature rises to 80°C, add 130g PAPI, and then add 2g dibutyltin dilaurate (DBTDL) catalyst, React at 80-95°C for 3-7 hours to obtain a prepolymer solution and cool it down to room temperature, add 40g of PAPI and 2g of triethanolamine (TEOA) and stir evenly, then add 30g of foam stabilizer AK-8805 and 15g of deionized The water is stirred at a high speed of 1000-2000r / min for 10-20s and foamed freely to obtain a foam intermediate, and finally the foam intermediate is placed in a vacuum drying oven at a high temperature of 160-220°C for 4-6 hours, so that The foam intermediate is fully imidized to obtain polyimide rigid foam.

Embodiment 3

[0029] 100g PMDA and 25g methyl alcohol are added in 100g DMF and react to clarification at a certain temperature, then gradually heat up, in the process that temperature rises to 80 ℃, add 130g PAPI, then add catalyst dibutyltin dilaurate (content is 0.74wt %), reacted at 80-95°C for 3-7 hours to obtain a prepolymer solution and cooled to room temperature, then added 40g of PAPI and triethanolamine (0.74wt%) and stirred evenly, then added 30g of foam stabilizer AK- 8805 and 15g of deionized water are stirred at a high speed of 1000-2000r / min for 10-20s and foamed freely to obtain a foam intermediate, and finally the foam intermediate is placed in a vacuum drying oven at 160-220°C for high temperature treatment4 ~6 hours, the foam intermediate is fully imidized, and the scanning electron microscope photo of the polyimide rigid foam is as follows figure 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com