Preparation method of MOF derived different-structure nanoreactor

A technology of nano-reactors and structure regulators, applied in chemical instruments and methods, preparation of organic compounds, preparation of ethers, etc., can solve the problem of poor dispersion of active catalytic centers, affecting catalytic activity of catalytic materials, low catalytic reaction efficiency, etc. problems, to achieve the effect of reliable and easy synthesis process, reliable preparation method and structure regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

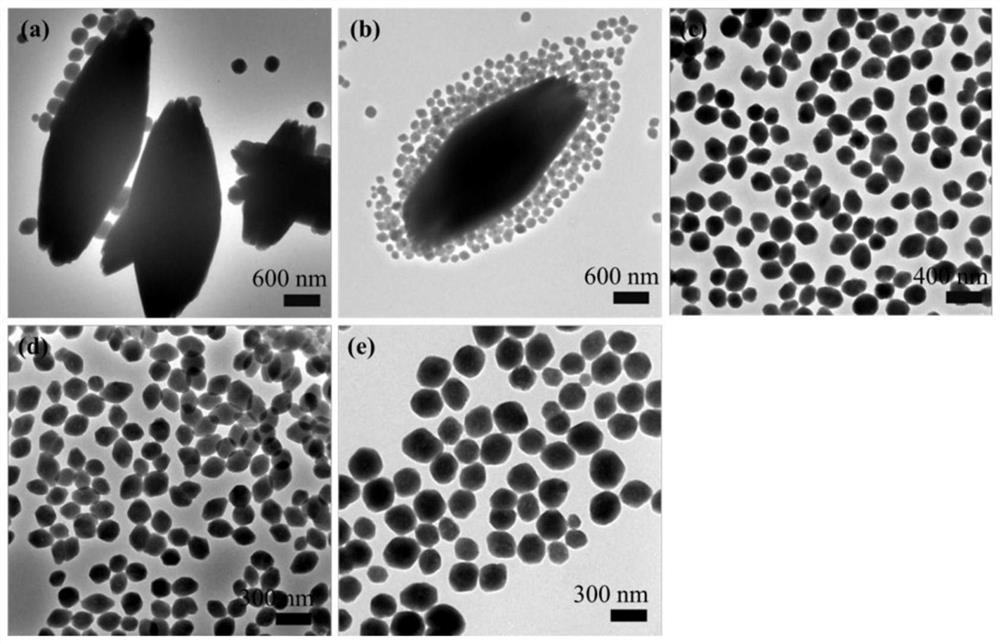

Image

Examples

preparation example Construction

[0047] 6) Preparation of different structural type nanoenen reactors: The above-described different structural type nanogenator precursor is calcined in air, and by using a step-by-step ultrasonic or equivalent impregnation method on the reactor carrier. After the calcination, the nano-reactor catalytic material of the corresponding structural type is reduced.

[0048] Application of nano-reactor catalytic material prepared by the above method in the field of catalytic.

[0049] Catalyst Co 2 Hydrocatalytic performance evaluation:

[0050] Nano reactor catalyst and industrial catalyst (ind.cat) will be prepared for in situ H. 2 Restore is activated, followed by the reaction mixture for CO 2 Hydrogen-catalyzed performance evaluation, where the activation process is: at normal pressure of 300 ° C hydrogen conditions at a hydrogen gas conditions of 2 ° C / min, the reaction conditions are: hydrogen flow is 30 ~ 60 ml / min, h 2 Co 2 Volume ratio = 3 / 1, vacancy is 9000 ~ 18000mlg -1 h...

Embodiment 1

[0052] Preparation of Core @ m-shell nuclear housing nano reactor:

[0053] Preparation of 1 mil-96 nucleus: 0.69 g of aluminum nitrate, 0.24 g of ketzene trimethyl and 2.1 g of PVP and 46 mL of ethanol acetone mixed solution (volume ratio of 1: 1), 10 ml ultrapure water, form a uniform mixed solution ;

[0054] The acid medium (nitric acid is added to the mixed solution, and the concentration of 1 mol / L) is mixed and uniformly transferred to a reaction kettle 150 ° C crystallization time of 42 h, centrifuged, ethanol washing 2 times after 80 ° C oven 12h Dry, get the morphology, MIL-96 in size.

[0055] 2MIL-96 @ msio 2 Preparation: MIL-96, which is called 50 mg height dispersion and particle diameter as reactor, and dispersed its ultrasonic dispersion in a mixed solution containing 131 mg of CTAb ethanol and water to obtain a solution of MOFS material, ethanol and water. The ratio was 0.85: 1, and the ethanol solution containing orthodoxate (TEOS) was mixed with the above alum...

Embodiment 2

[0060] Double-shell Hollow Mesoporous-shaped nano reactor preparation:

[0061] The preparation of 1 mil-96 nucleus was weighed 0.69 g of aluminum nitrate, 0.24 g of a phenylene trimethylene acid and 2.1 g of PVP and 46 mL of ethanol acetone mixed solution (volume ratio of 1: 1), 10 ml of water agitated to form a mixed solution;

[0062] The acid medium (nitric acid is added to the mixed solution, and the concentration of 1 mol / L of the mixed solution is mixed) and then transferred to the reaction kettle 150 ° C crystallization time of 42 h, centrifugation, ethanol washing 2 to 3 times after 80 ° C The oven is dried 12h.

[0063] 2MIL-96 @ msio 2 The preparation of 50 mg height dispersed and particle size uniform MIL-96 as the reactor intematic, dispersed its ultrasonic dispersion in a mixed solution containing 131 mg of CTAb ethanol and water to obtain a solution, ethanol and water volume ratio of MOFS material, ethanol and water volume ratio In 0.67: 1, the ethanol solution co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com