Novel sheet stacked spherical structure rare earth oxysulfide and preparation method and application thereof

A rare earth sulfur oxide, a new type of technology, applied in the preparation/processing of rare earth metal compounds, rare earth metal sulfides, chemical instruments and methods, etc., can solve the problems of uneven product size, irregular morphology, and environmental pollution, etc. To achieve the effect of simple preparation method, high yield and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

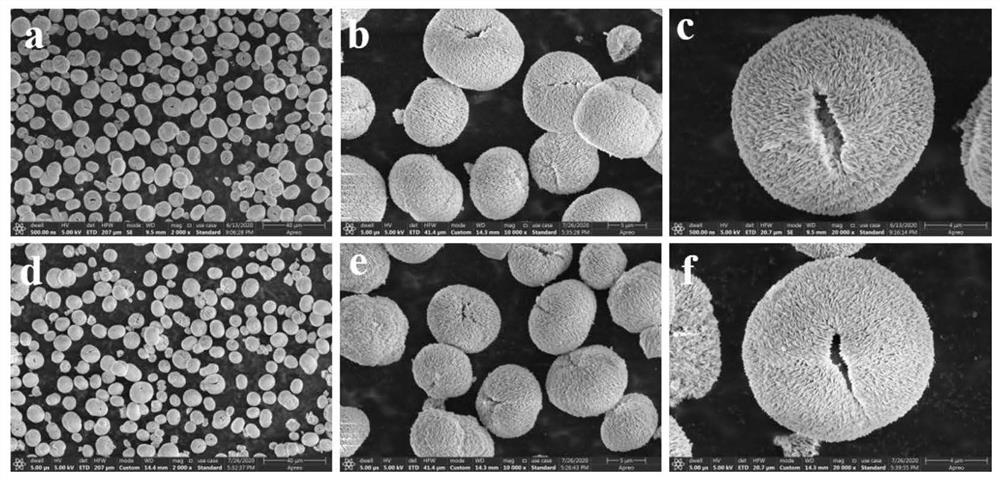

[0049] Weigh 1mmol of rare earth gadolinium nitrate (0.451g), 1.2mmol of ammonium persulfate (0.274g) in a 25mL glass bottle, add 8mL of ethanol and 8mL of water, stir well in the hydrothermal reaction kettle, and then raise the temperature of the reaction kettle to 110°C , keep 3h. Take out the reaction kettle and cool it to room temperature, wash with ethanol / water mixed solvent with a volume ratio of 1:1, suction, filter and dry to obtain a composite phase rare earth gadolinium oxysulfide. Then at 5% H 2 / 95%N 2 Calcined at 850°C for 2 hours under a mixed atmosphere to obtain a single-phase rare earth gadolinium oxysulfide (Gd 2 o 2 S).

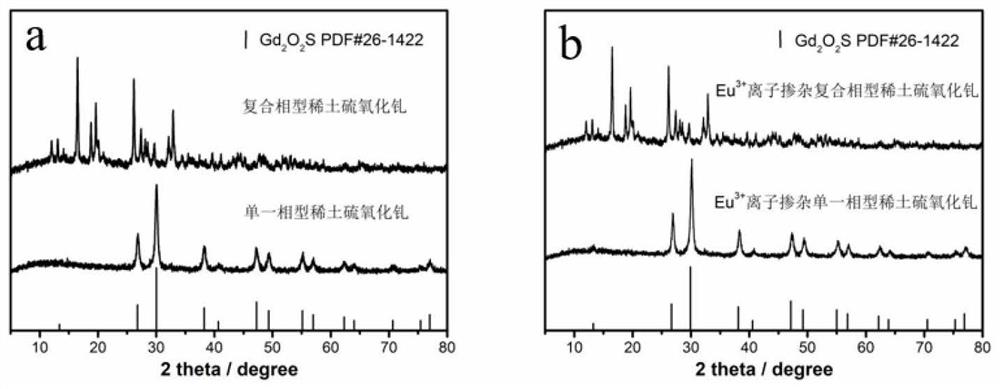

[0050] figure 1 Middle (a) is the xrd characterization figure of composite phase type and single phase type rare earth gadolinium oxysulfide prepared in this embodiment, as can be seen from the results in the figure, rare earth sulfur oxide can be realized from composite phase type to The transformation of the crystalline phase of a ...

Embodiment 2

[0053] Take by weighing the mixture of 1mmol rare earth gadolinium nitrate (0.406g) and europium nitrate (0.045g) (control Eu 3+ The molar weight of ions accounts for 10% of the total molar weight of rare earth ions), 1.5mmol (0.342g) of ammonium persulfate is placed in a 25mL glass bottle, 8mL of ethanol and 8mL of water are added, in a hydrothermal reactor, stir well, and then the reaction The kettle was heated to 110°C and kept for 3h. Take out the reactor and cool it to room temperature, wash with ethanol / water mixed solvent with a volume ratio of 1:1, filter and dry to obtain Eu 3+ Ion-doped complex-phase rare earth gadolinium oxysulfide. Then at 5% H 2 / 95%N 2 Calcined at 850°C for 2h under a mixed atmosphere to obtain single-phase Eu 3+ Ion-doped rare earth gadolinium oxysulfide (Gd 2 o 2 S:Eu 3+ ).

[0054] figure 1 (b) is Eu 3+ The xrd characterization diagrams of the ion-doped complex-phase and single-phase rare earth gadolinium oxysulfide, as can be seen f...

Embodiment 3

[0059] Weigh the mixture of 1mmol rare earth yttrium nitrate (0.364g) and europium nitrate (0.023g) (control Eu 3+ The molar weight of ions accounts for 5% of the total molar weight of rare earth ions), 1.5mmol (0.342g) of ammonium persulfate is placed in a 25mL glass bottle, 8mL of ethanol and 8mL of water are added, in a hydrothermal reactor, stir well, and then the reaction The kettle was heated to 110°C and kept for 3h. Take out the reactor and cool it to room temperature, wash with ethanol / water mixed solvent with a volume ratio of 1:1, filter and dry to obtain Eu 3+ Ion-doped complex-phase rare earth yttrium oxysulfide. Then at 5% H 2 / 95%N 2 Calcined at 850°C for 2h under a mixed atmosphere to obtain single-phase Eu 3+ Ion-doped rare earth yttrium oxysulfide (Y 2 o 2 S:Eu 3+ ).

[0060] Figure 4 (a) is Eu 3+ The xrd characterization diagrams of ion-doped composite-phase and single-phase rare earth yttrium oxysulfide, as can be seen from the results in the fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com