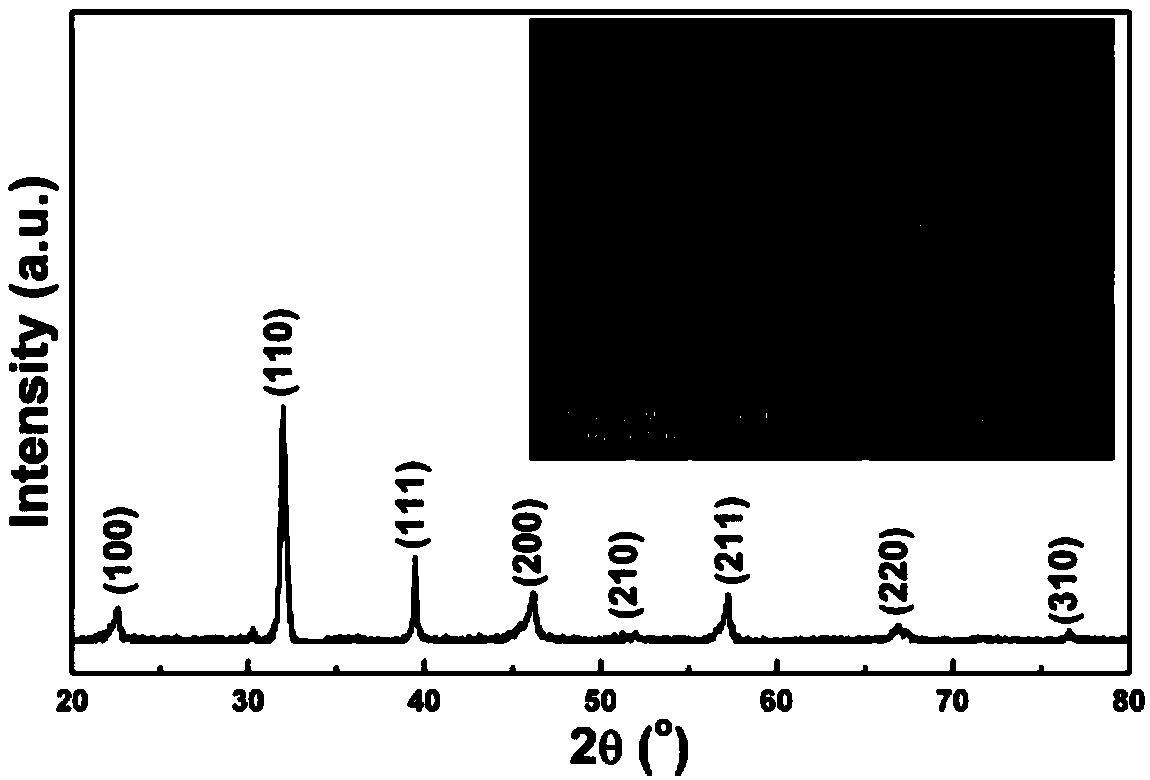

Morphotropic phase boundary potassium-bismuth titanate-based leadless relaxor ferroelectric ceramic preparation method

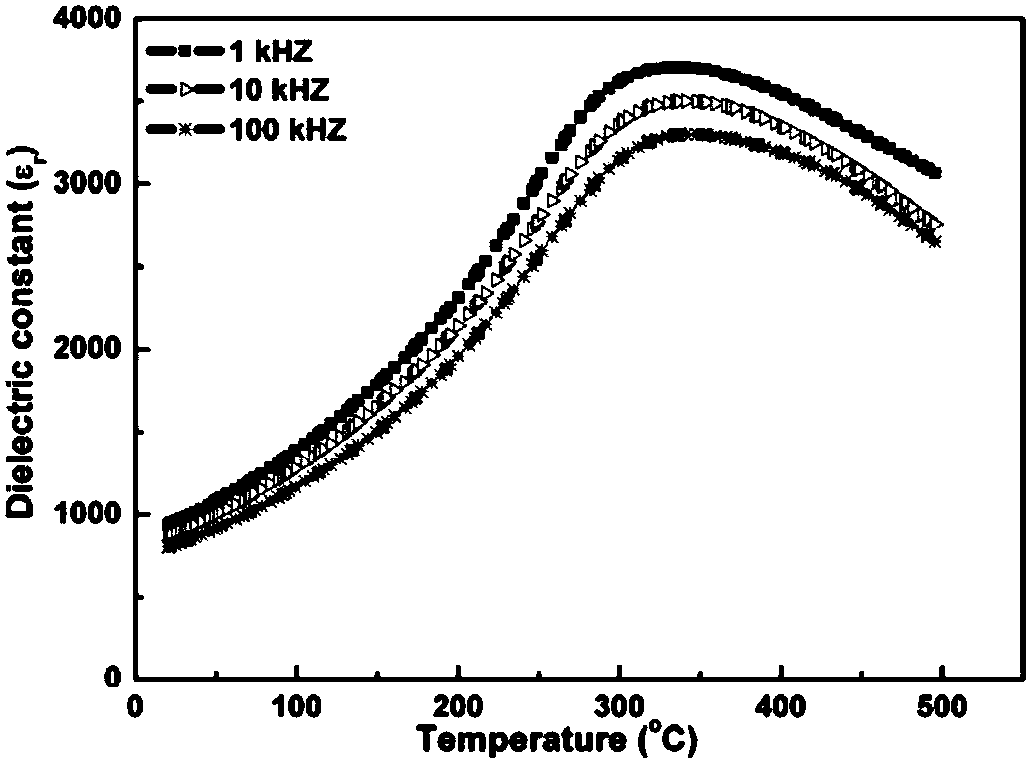

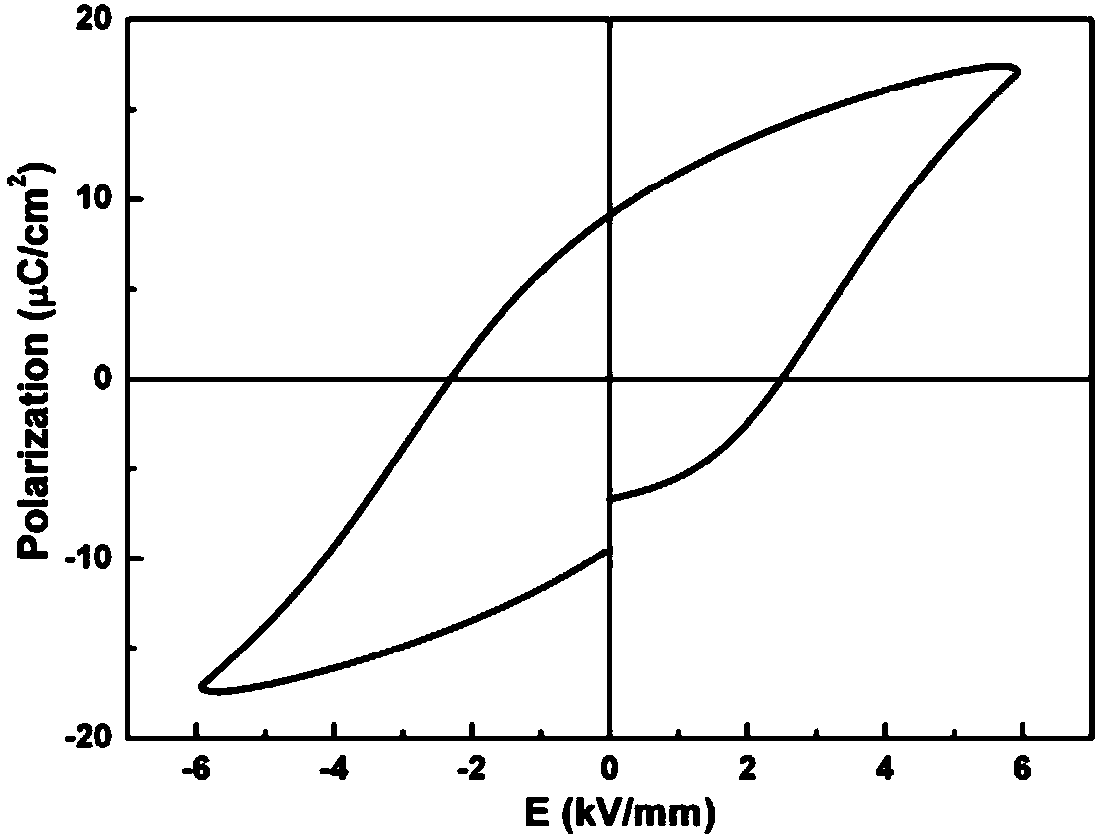

A quasi-isomorphic phase boundary, bismuth potassium titanate technology, applied in the field of preparation of bismuth potassium titanate-based lead-free relaxor ferroelectric ceramics, to achieve good temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) select the raw material Bi whose purity is greater than 99% 2 o 3 , K 2 CO 3 ,TiO 2 , La 2 o 3 ,TiO 2 , 4 (MgCO 3 )·Mg(OH) 2 ·5H 2 O as a raw material for bismuth potassium titanate-based lead-free relaxor ferroelectric ceramics. According to the chemical formula 0.99Bi 0.5 K 0.5 TiO 3 -0.01La(Mg 0.5 Ti 0.5 )O 3 Weighing, adding absolute ethanol to the nylon tank for ball milling, discharging, and drying. The ball milling time was 8 hours, and the drying temperature was 120°C. Put the dried powder into a corundum crucible, tamp it, cover the crucible, put it into a muffle furnace for calcination, raise it to 920 ℃ at 5°C / min, keep it warm for 2 hours, and calcine twice.

[0031] (2) Secondary ball milling of the synthesized powder obtained in step (1), discharging and drying. The drying temperature is the same as in step (1), and the ball milling time is 12 hours. Add an appropriate amount of 5wt% PVA to the dried powder for granulation, and press...

Embodiment 2

[0037] (1) select the raw material Bi whose purity is greater than 99% 2 o 3 , K 2 CO 3 ,TiO 2 , La 2 o 3 ,TiO 2 , 4 (MgCO 3 )·Mg(OH) 2 ·5H 2 O as a raw material for bismuth potassium titanate-based lead-free relaxor ferroelectric ceramics. According to the chemical formula 0.99Bi 0.5 K 0.5 TiO 3 -0.01La(Mg 0.5 Ti 0.5 )O 3 Weighing, adding absolute ethanol to the nylon tank for ball milling, discharging, and drying. The ball milling time was 8 hours, and the drying temperature was 120°C. Put the dried powder into a corundum crucible, tamp it, cover the crucible, put it into a muffle furnace for calcination, raise it to 920 ℃ at 5°C / min, keep it warm for 2 hours, and calcine twice.

[0038] (2) Secondary ball milling of the synthesized powder obtained in step (1), discharging and drying. The drying temperature is the same as in step (1), and the ball milling time is 12 hours. Add an appropriate amount of 5wt% PVA to the dried powder for granulation, and press...

Embodiment 3

[0044] (1) select the raw material Bi whose purity is greater than 99% 2 o 3 , K 2 CO 3 ,TiO 2 , La 2 o 3 ,TiO 2 , 4 (MgCO 3 )·Mg(OH) 2 ·5H 2 O as a raw material for bismuth potassium titanate-based lead-free relaxor ferroelectric ceramics. According to the chemical formula 0.99Bi 0.5 K 0.5 TiO 3 -0.01La(Mg 0.5 Ti 0.5 )O 3 Weighing, adding absolute ethanol to the nylon tank for ball milling, discharging, and drying. The ball milling time was 8 hours, and the drying temperature was 120°C. Put the dried powder into a corundum crucible, tamp it, cover the crucible, put it into a muffle furnace for calcination, raise it to 920 ℃ at 5°C / min, keep it warm for 2 hours, and calcine twice.

[0045] (2) Secondary ball milling of the synthesized powder obtained in step (1), discharging and drying. The drying temperature is the same as in step (1), and the ball milling time is 12 hours. Add an appropriate amount of 5wt% PVA to the dried powder for granulation, and press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com