SMD safety ceramic capacitor

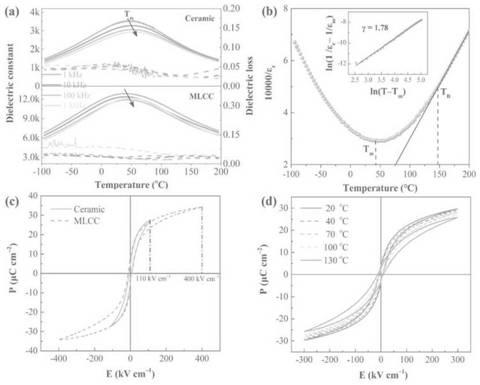

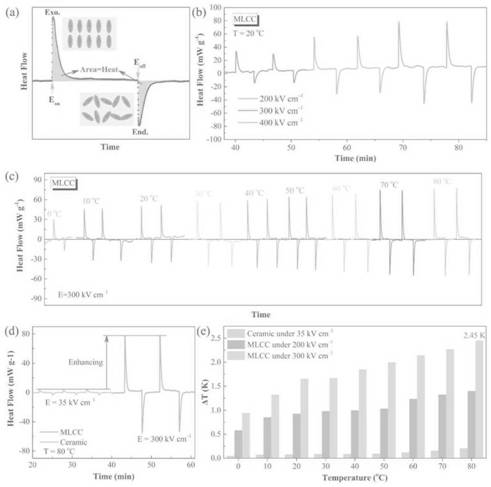

A technology of ceramic capacitors and safety regulations, which is applied in the direction of laminated capacitors, fixed capacitor electrodes, fixed capacitor dielectrics, etc., can solve the problems of low breakdown electric field, affecting capacitor work, poor stability, etc., and achieve enhanced breakdown electric field, large current Card effect, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

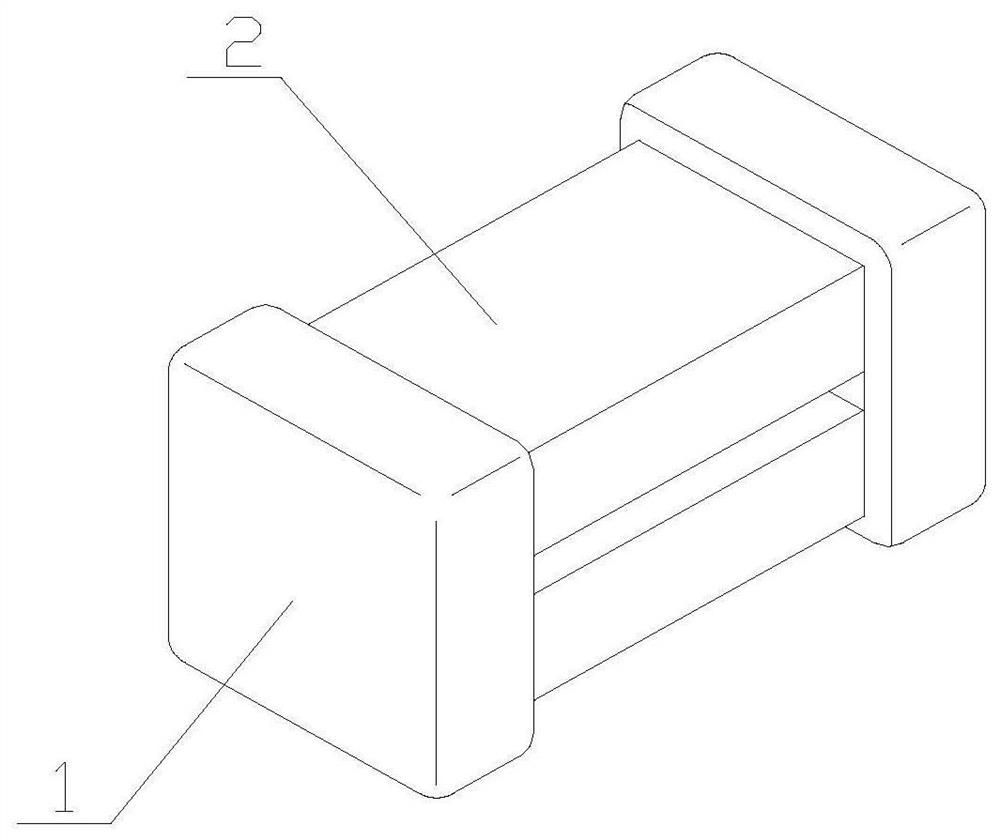

[0032] A patch conventional ceramic capacitor of the present invention is achieved, a patch confidence ceramic capacitor: a terminal electrode 1, MLCC2, and an end electrode 1 symmetrical in the end of the MLCC2, MLC2 built-in multilayer electrode 22 The inner electrode 22 and the end electrode 1 are connected, and the middle portion of the LLCC is laterally disposed in the hollow structure, the inner electrode 22 is a corrugated structure, and the ceramic 20 of MLCC2 is prepared by a casting process;

[0033] The end electrode 1 is a multilayer structure, which is sequentially connected to the copper layer 13, the soft terminal layer 12, the nickel layer 11, the tin layer 10, the soft terminal layer 12, and the copper layer 13 are connected to nickel. The outer surface of the layer 11 is provided with irregular projections, the bump height is 0.2mm, and the tin layer 10 is bonded by irregular projections and nickel layer 11;

[0034] The inner electrode 22 is a copper foil, a cop...

Embodiment 2

[0043] A patch conventional ceramic capacitor of the present invention is achieved, a patch confidence ceramic capacitor: a terminal electrode 1, MLCC2, and an end electrode 1 symmetrical in the end of the MLCC2, MLC2 built-in multilayer electrode 22 The inner electrode 22 and the end electrode 1 are connected, and the middle portion of the LLCC is laterally disposed in the hollow structure, the inner electrode 22 is a corrugated structure, and the ceramic 20 of MLCC2 is prepared by a casting process;

[0044] The end electrode 1 is a multilayer structure, which is sequentially connected to the copper layer 13, the soft terminal layer 12, the nickel layer 11, the tin layer 10, the soft terminal layer 12, and the copper layer 13 are connected to nickel. The outer surface of the layer 11 is provided with irregular projections, the bump height is 0.5 mm, and the tin layer 10 is bonded by irregular projections and nickel layer 11;

[0045] The inner electrode 22 is a copper foil, a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com