Polymer-based composite material and preparation method thereof

A technology for polymer materials and composite materials, applied in the field of polymer matrix composite materials and their preparation, can solve the problems of increased dielectric loss tangent, decreased breakdown electric field, and difficulty in practical application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] In the last part of the application, the preparation of the polymer-based composite material is carried out, that is, the polymer material, the modified negatively charged inorganic nano-sheets are mixed with a solvent, and the polymer-based composite material is obtained after casting. The solvent in the present invention refers to a solvent that can dissolve the selected polymer material, which can be adjusted by itself due to the substrates of different polymer materials selected, for example but not limited to, when the substrate is a fluorine-containing copolymer, For example, in the case of polyvinylidene fluoride, the substrate solvent may be N,N-dimethylformamide.

[0058] Preferably, after the step of mixing the modified negatively charged inorganic nanosheets with the polymer material and casting to obtain the polymer-based composite material, further including uniaxial stretching treatment of the polymer-based composite material, In order to obtain the polyme...

Embodiment 1

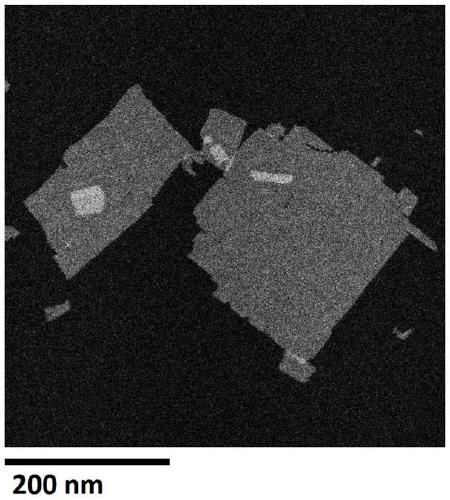

[0074] Example 1 Preparation of Modified Negatively Charged Inorganic Nanosheets

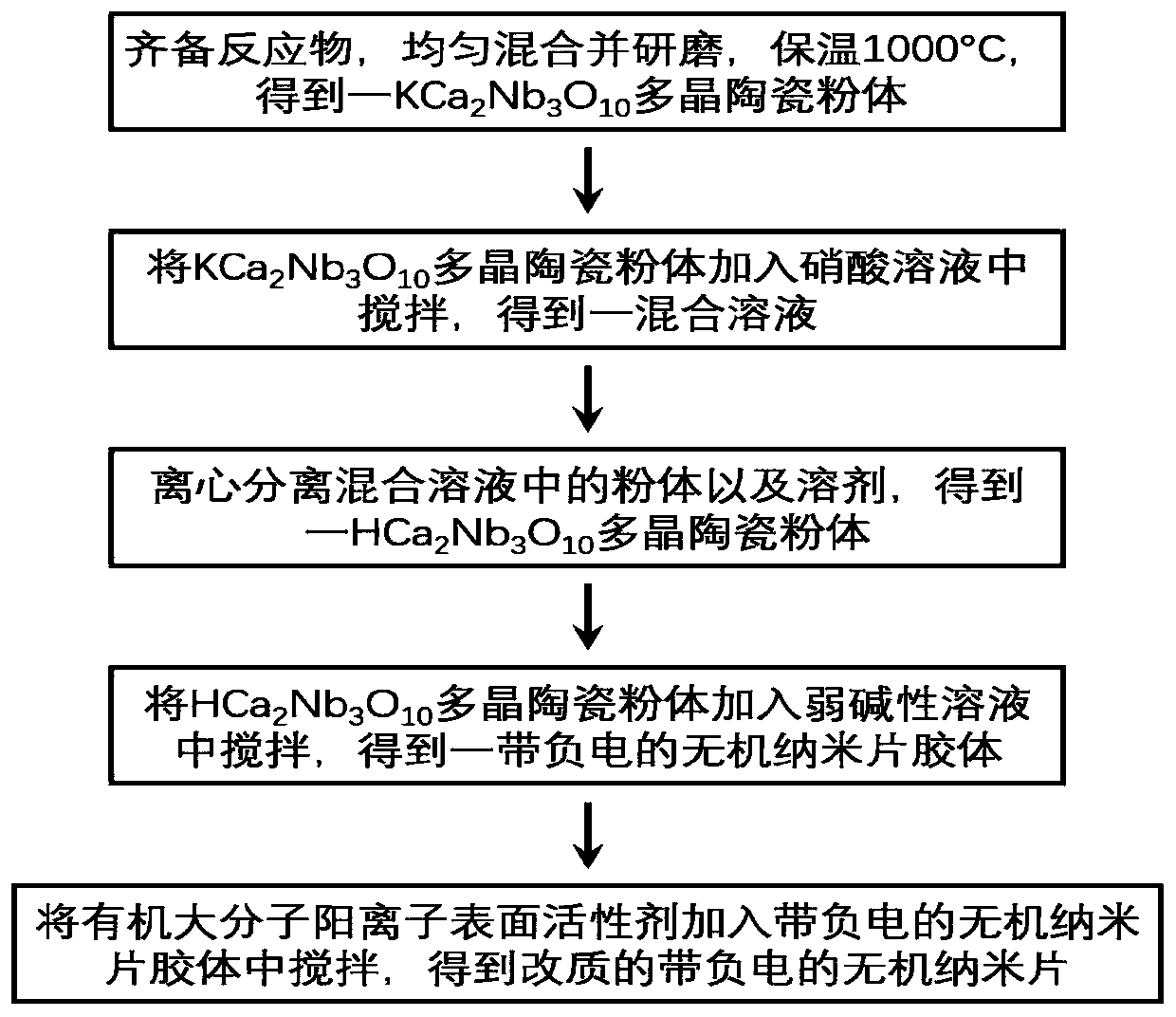

[0075] In this example, negatively charged inorganic nanosheets and polyethyleneimine are used to prepare modified negatively charged inorganic nanosheets, so that the surface of the negatively charged inorganic nanosheets is modified by polyethyleneimine. Please refer to figure 1 , and its detailed preparation method is as follows:

[0076] First, the reactants are prepared, and the reactants are potassium carbonate powder, calcium carbonate powder, and niobium oxide powder;

[0077] Mix the three powders evenly according to the stoichiometric ratio, and continue to grind them in an agate mortar for 3 hours, so that the reagents are mixed evenly and the particle size of the reactants is reduced. Insulated in a type resistance furnace to 1000-1200°C for 2-5 hours to obtain KCa 2 Nb3 o 10 Polycrystalline ceramic powder;

[0078] Next, the KCa 2 Nb 3 o 10 The polycrystalline ceramic powder ...

Embodiment 2

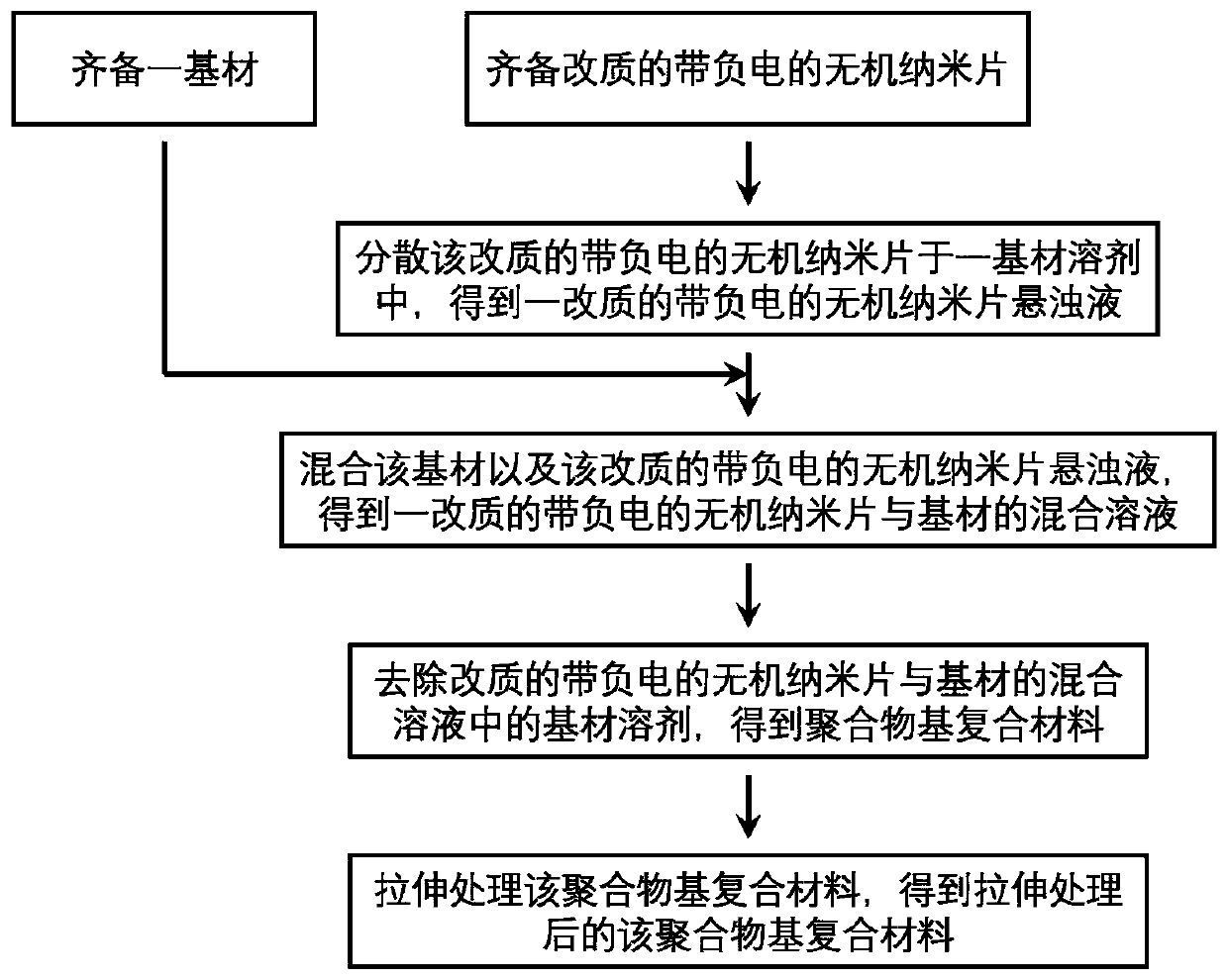

[0083] Embodiment 2 prepares polymer-based composite material

[0084] Mix the modified negatively charged inorganic nanosheets prepared in Example 1 with polyvinylidene fluoride as a substrate to prepare a polymer-based composite material, please refer to image 3 , and its detailed preparation method is as follows:

[0085] The modified Ca prepared in Example 1 is ready 2 Nb 3 o 10 Nanosheets;

[0086] Dispersing the modified negatively charged inorganic nanosheets in N,N-dimethylformamide solvent, followed by stirring for 5 hours to obtain a modified negatively charged inorganic nanosheet suspension;

[0087] Mix the polyvinylidene fluoride material and the above-mentioned negatively charged inorganic nanosheet suspension and stir at room temperature for 10 hours to obtain a mixed solution of the modified negatively charged inorganic nanosheet and the substrate, wherein the modified negatively charged Based on the total mass of the inorganic nanosheets and the substrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com