A kind of lanthanum-doped lead zirconate titanate ferroelectric thick-film ceramic material and preparation method thereof

A lead zirconate titanate, ferroelectric thick film technology, applied in the field of ferroelectric ceramic materials, can solve the problems of low working voltage, low breakdown electric field strength of PLZT ceramics, low breakdown electric field strength, etc. Resistance to breakdown electric field strength, the effect of solving the dispersion problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

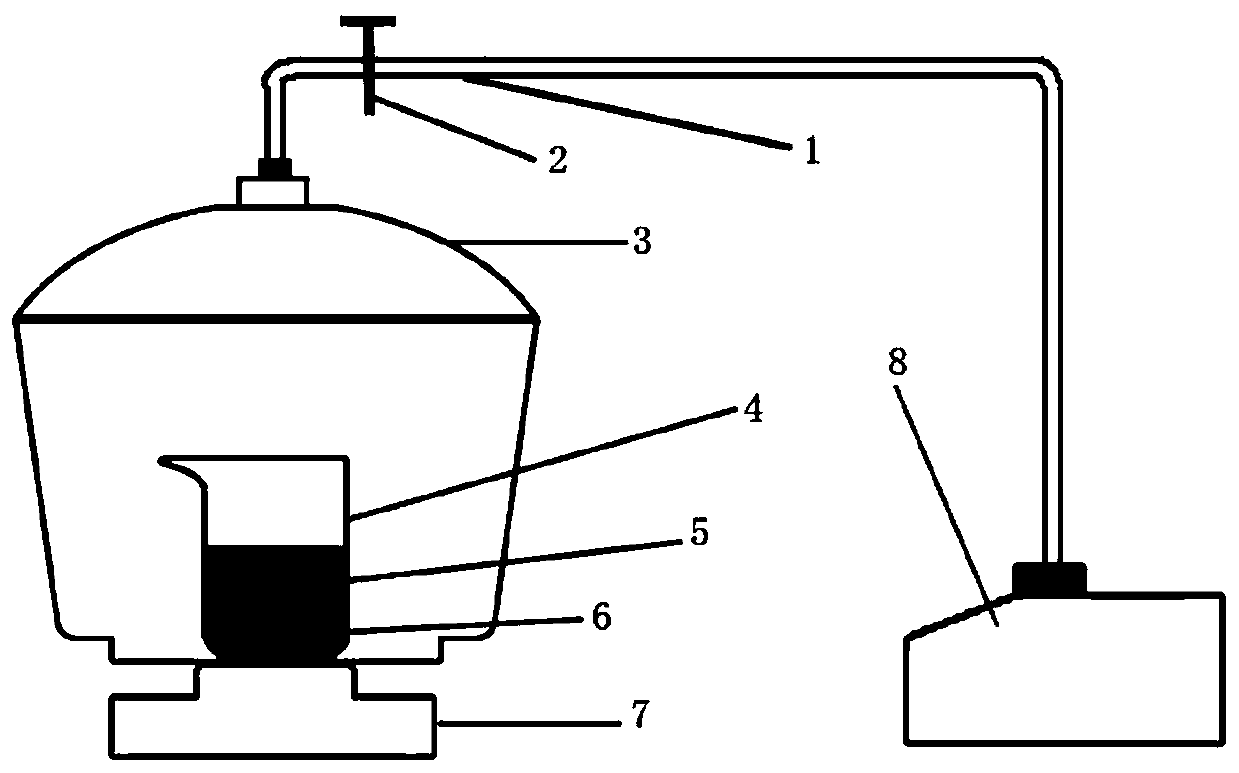

[0038] Example 1 Construction of a simple vacuum defoaming device

[0039] figure 1 It is a simple vacuum defoaming device built by oneself. Among them, 1 is a vacuum rubber tube, 2 is a three-way valve, 3 is a vacuum drying dish, 4 is a beaker, 5 is a PLZT slurry, 6 is a magnetic rotor, 7 is a magnetic stirrer, and 8 is a vacuum pump. The upper port of the vacuum drying dish 3 is connected to the three-way valve 2 with a vacuum rubber tube 1, and then connected to a vacuum pump 8. The exhaust gas of the vacuum drying dish is connected through the three-way valve 2, and the air bubbles will overflow from the slurry under negative pressure to achieve the purpose of defoaming. The PLZT slurry 5 to be defoamed is placed in the vacuum drying dish 3 . The vacuum drying dish 3 is placed on the magnetic stirrer 7, and the magnetic rotor 6 built into the PLZT slurry solution is used for stirring, and the magnetic heating stirrer can be heated as required. The vacuum drying dish 3 ...

Embodiment 2

[0040] Example 2 Preparation of lanthanum-doped lead zirconate titanate ferroelectric thick film ceramics

[0041] 1. According to Pb 0.92 La 0.08 (Zr 065 Ti 0.35 ) 0.98 o 3 For the ceramic formula, refer to the capacity of the ball mill tank to accurately calculate the required quality of lead oxide, zirconium dioxide, titanium dioxide, and lanthanum oxide. In order to prevent the volatilization of lead oxide during the sintering process, add 2wt% more than the original formula in the ingredients. Lead oxide PbO powder, the charging volume is about 2 / 3 of the total volume of the grinding tank, which is about 167ml.

[0042] 2. Alcohol is used as the ball milling medium, the volume ratio of alcohol, abrasive material, and balls is 2:1:2, and the mixing ball milling time is set to 18 hours.

[0043] 3. After ball milling, place the abrasive mixture in an oven for dehydration.

[0044] 4. Carry out pre-sintering, set the temperature from room temperature to 100°C at a rat...

Embodiment 3

[0051] 9. The PLZT blank film after the cold isostatic pressing process should be sintered. The sintering process starts from room temperature, raises the temperature to 600°C at a rate of 5°C / min, and keeps the temperature for 3h. Then the temperature was raised to 1300°C at a rate of 10°C / min, kept for 3 hours, and the temperature was naturally lowered with the furnace after sintering. Ceramic products after sintering. Embodiment 3 performance test

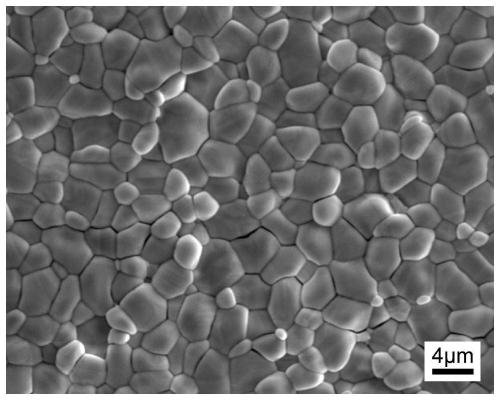

[0052] figure 2 It is the SEM image of PLZT green film. It can be seen from the figure that the crystal grains are relatively uniform, the growth is complete, there are no obvious pores, and the grain size is 3-5 μm. image 3 It is the SEM image of the PLZT thick film ceramic after sintering. It can be seen that the crystal grains are also relatively uniform and fully grown, without obvious pores, and the grain size is 2-4 μm. Compared with before sintering, the size of grains is slightly reduced, indicating that the thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com