Silicon/fluoroether/fluorosilicone composite rubber material and preparation method thereof

A technology of composite rubber and fluorosilicone rubber, which is applied in the field of silicon/fluoroether/fluorosilicone composite rubber materials and its preparation, to achieve the effects of simple production process, wide range of industrial applications, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation method of the graphene-modified silicone rubber containing fluorine ionic liquid modification, comprises the steps:

[0038] (1) Mix 1 g of fluorine-containing ionic liquid 1-aminopropyl-3-methylimidazole trifluoromethanesulfonimide salt, 2 g of graphite oxide, and 100 mg of catalyst p-dimethylaminopyridine in 200 mL of ethanol, and ultrasonically treat in a water bath for 3 h After the graphite oxide is uniformly dispersed, react at 50°C for 16 hours in a nitrogen atmosphere to obtain fluorine-containing ionic liquid grafted graphite oxide. The reaction product is purified by centrifugal washing to remove unreacted ionic liquid and catalyst, and the product is vacuum-dried;

[0039] (2) Weighing 2 g of graphite oxide grafted in step (1) and placing it in a tongs pot, and heat-treating it in an oven at 250° C. for 2 hours to obtain a fluffy flocculent ionic liquid-modified redox functional graphene product;

[0040] (3) Mix 2 g of fluorine-containing ion...

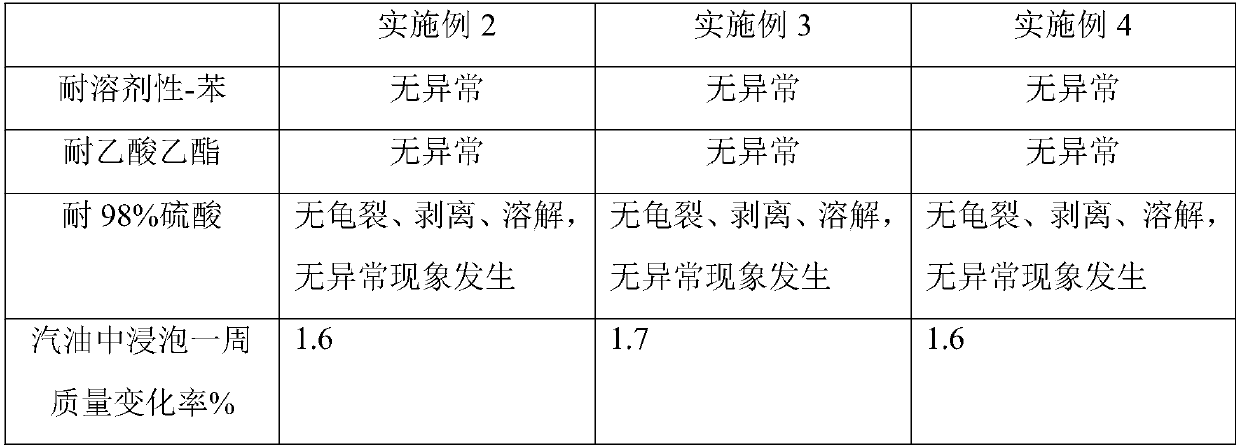

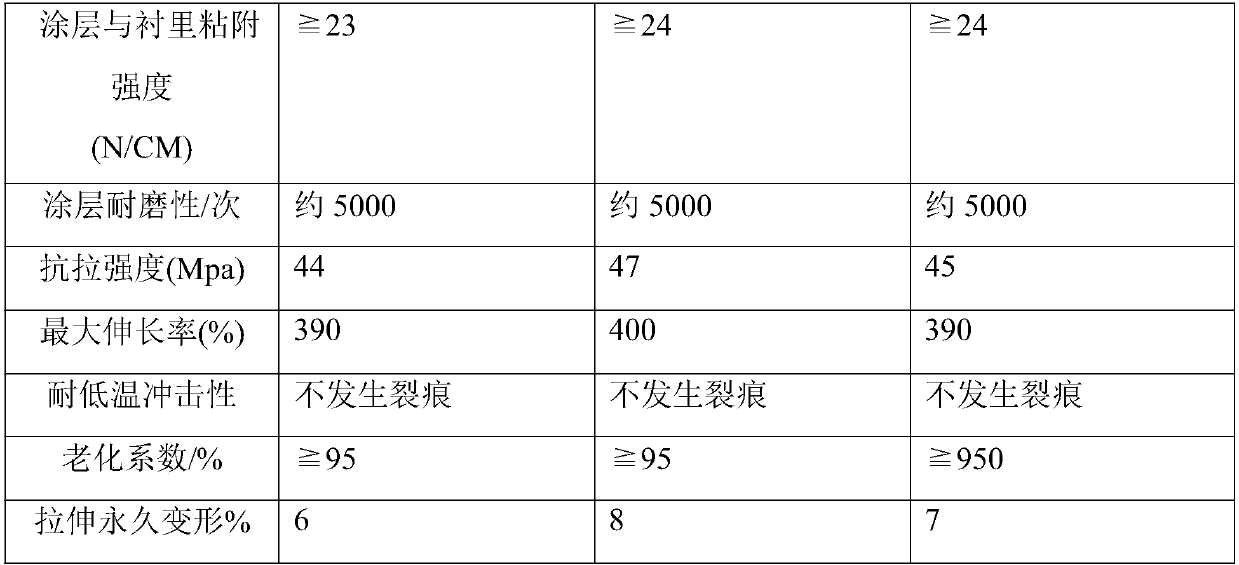

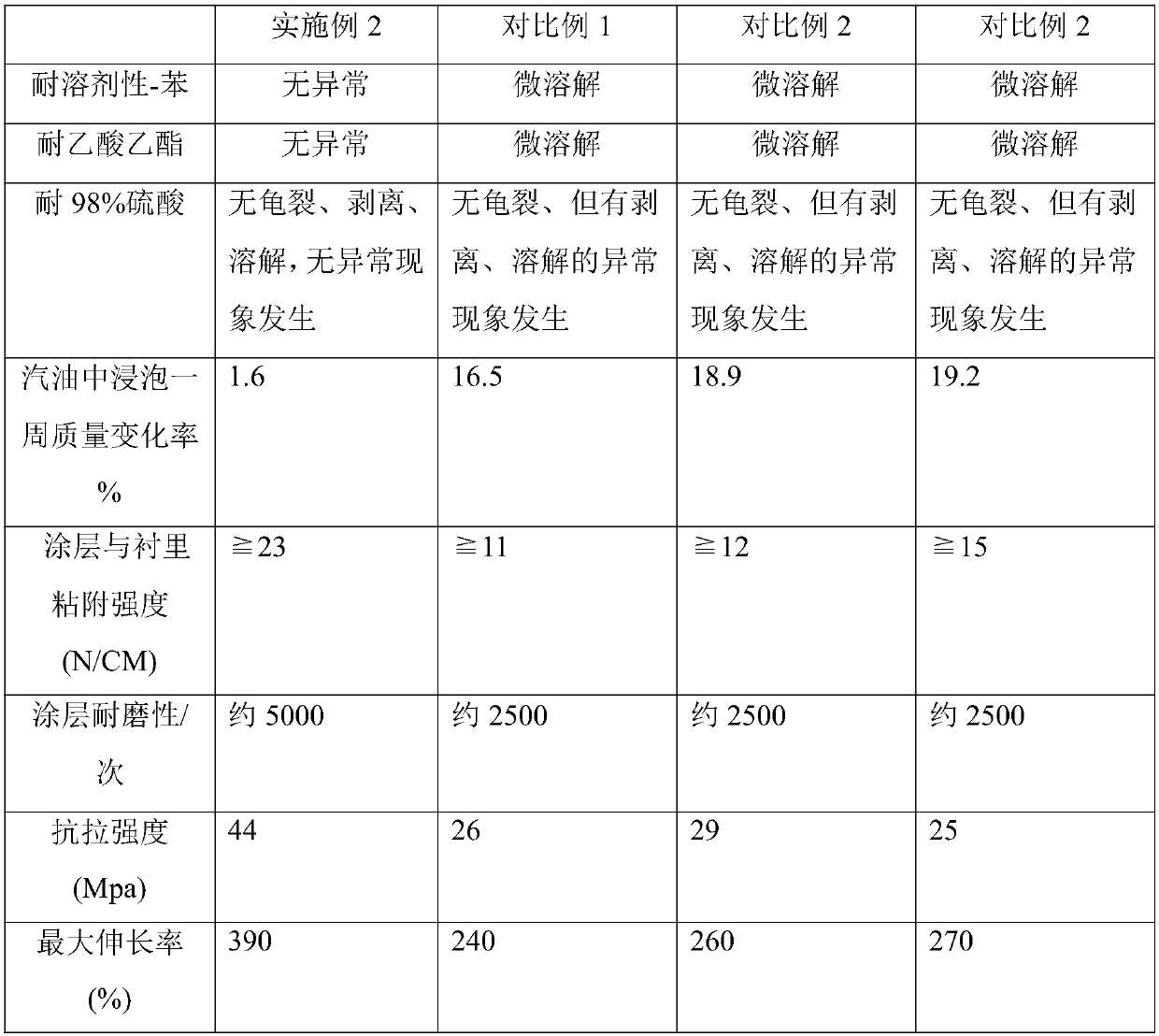

Embodiment 2

[0052] A preparation method of silicon / fluoroether / fluorosilicone composite rubber material, comprising the steps of:

[0053] (1) Blend 20 parts of silicone rubber, 65 parts of fluoroether rubber, and 50 parts of fluorosilicone rubber on the open mill, and then put them into the internal mixer, and then add 12 parts of nano-zinc oxide and 12 parts of modified montmorillonite 8 parts of calcium stearate, 10 parts of white carbon black, and 8 parts of anti-aging agent were mixed for 45 minutes at a temperature of 70 ° C, and left to stand for 8 hours to obtain the compounded compound A;

[0054] (2) Add the above-mentioned mixed rubber material A to the open-training machine, then add 16 parts of 2-mercaptobenzothiazole and 6 parts of accelerator TMTD, and shape it after 10 minutes of kneading, and let it stand for 16 hours to obtain the molding rubber material B;

[0055] (3) Put the molding compound B into the mold, place it on a flat vulcanizing machine for the first vulcani...

Embodiment 3

[0058] A preparation method of silicon / fluoroether / fluorosilicone composite rubber material, comprising the steps of:

[0059] (1) After blending 25 parts of silicone rubber, 105 parts of fluoroether rubber, and 70 parts of fluorosilicone rubber on the open mill, they were put into the internal mixer, and then 15 parts of nano-zinc oxide and 15 parts of modified montmorillonite were added. part, 12 parts of calcium stearate, 12 parts of white carbon black, and 10 parts of anti-aging agent were mixed at a temperature of 70°C for 45 minutes, and left to stand for 8 hours to obtain the compounded compound A;

[0060] (2) Add the above-mentioned mixed rubber material A to the open-training machine, then add 16 parts of 2-mercaptobenzothiazole and 6 parts of accelerator TMTD, and shape it after 10 minutes of kneading, and let it stand for 16 hours to obtain the molding rubber material B;

[0061] (3) Put the molding compound B into the mold, place it on a flat vulcanizing machine f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com