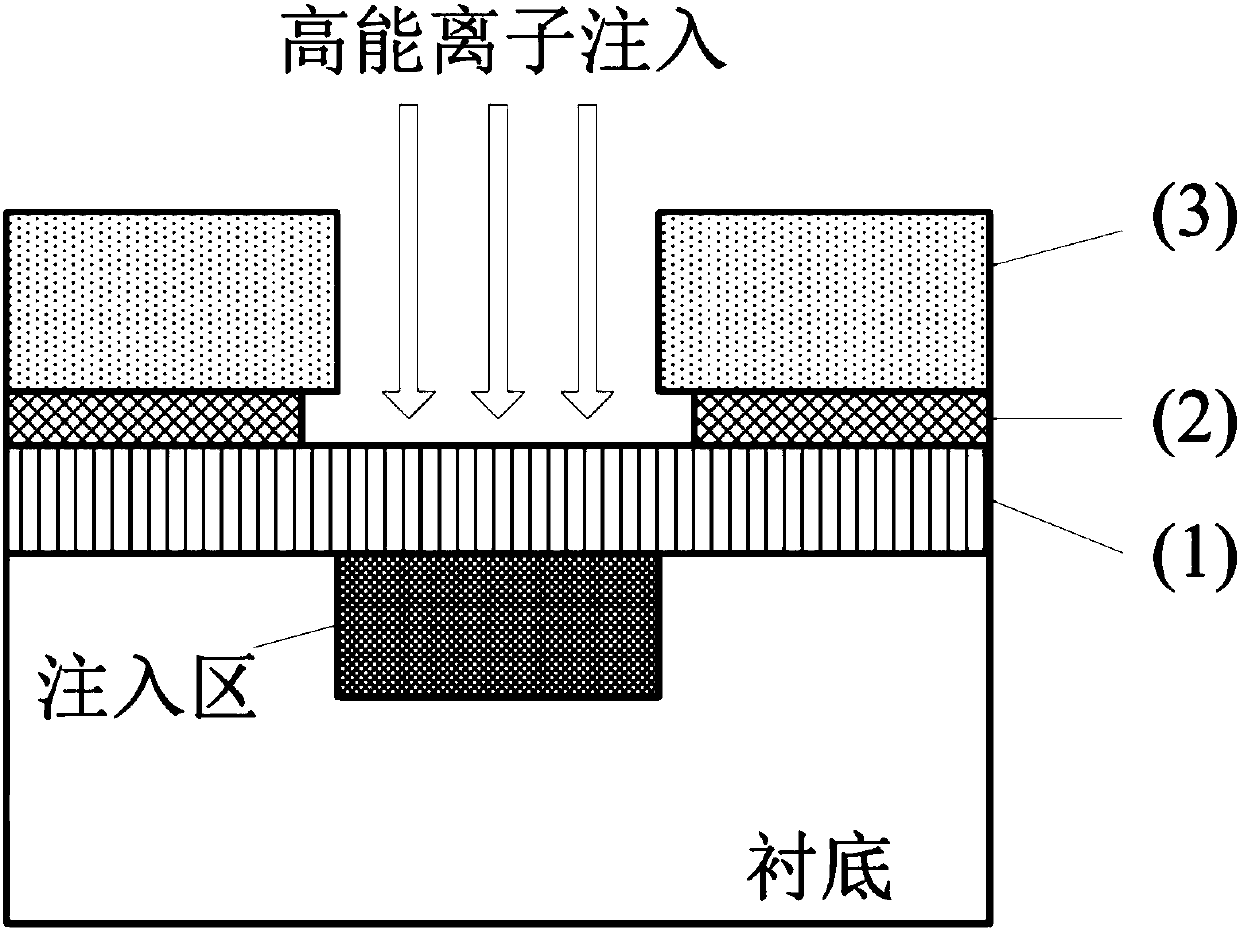

Easy-resist removing high-energy ion implantation multilayer mask manufacturing method

A multi-layer mask, high-energy ion technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of complex and difficult processes, multiple lithography and etching, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

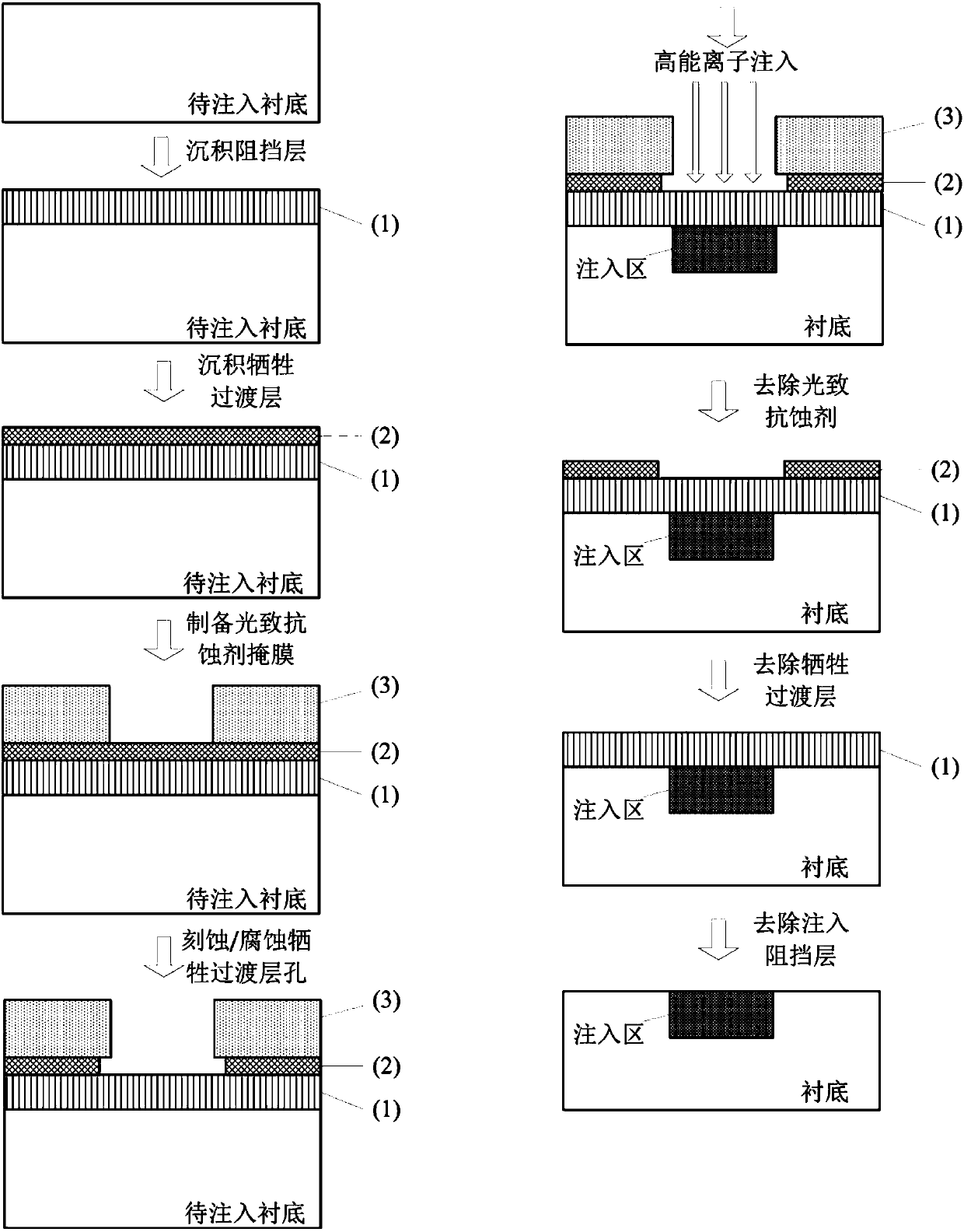

[0026] A 40nm thick cadmium telluride thin film is thermally evaporated and deposited on the substrate as an injection barrier layer, and then a 70nm thick zinc sulfide thin film is thermally evaporated and deposited as a sacrificial transition layer, according to the thickness of the sacrificial transition layer zinc sulfide≤implantation area Outer expansion error limit / tan (ion incident angle), for an implantation region outreach error of 0.1 μm and an implantation inclination angle of 7°, the condition is satisfied if the thickness of the zinc sulfide layer is less than 800 nm.

[0027] Clean and dry the chip on which the injection barrier layer and sacrificial transition layer have been deposited, spin-coat photoresist AZ1500 on the surface of the chip, and selectively expose and develop the chip to define the photoresist mask injection Area.

[0028] Using the photoresist injection area pattern as an etching mask, use pure hydrochloric acid at 0°C to corrode the injection...

Embodiment 2

[0031] A 300nm thick cadmium telluride thin film is thermally evaporated and deposited on the substrate as an injection barrier layer, and then a 300nm thick zinc sulfide thin film is thermally evaporated deposited as a sacrificial transition layer, according to the thickness of the sacrificial transition layer zinc sulfide ≤ implantation area Outer expansion error limit / tan (ion incident angle), for an implantation region outreach error of 0.1 μm and an implantation inclination angle of 7°, the condition is satisfied if the thickness of the zinc sulfide layer is less than 800 nm.

[0032] Clean and dry the chip on which the injection barrier layer and sacrificial transition layer have been deposited, spin-coat photoresist AZ5200 on the surface of the chip, and selectively expose and develop the chip to define the photoresist mask injection Area.

[0033]Using the photoresist implanted area pattern as an etching mask, use pure hydrochloric acid at 0°C to corrode the implanted ...

Embodiment 3

[0036] A 200nm-thick cadmium telluride thin film is thermally evaporated and deposited on the substrate as an injection barrier layer, and then a 70nm-thick zinc sulfide thin film is thermally evaporated deposited as a sacrificial transition layer, according to the thickness of the sacrificial transition layer zinc sulfide≤implantation area Outer expansion error limit / tan (ion incident angle), for an implantation region outreach error of 0.1 μm and an implantation inclination angle of 7°, the condition is satisfied if the thickness of the zinc sulfide layer is less than 800 nm.

[0037] Clean and dry the chip on which the injection barrier layer and sacrificial transition layer have been deposited, spin-coat photoresist AZ5200 on the surface of the chip, and selectively expose and develop the chip to define the photoresist mask injection Area.

[0038] Using the photoresist implanted region pattern as an etching mask, Ar:CH 4 :H 2 The mixed gas is an etching gas, and the zin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com