Preparation method of film capacitor composite dielectric film

A technology of composite dielectric film and film capacitors, applied in the direction of film/thick film capacitors, laminated capacitors, etc., can solve the problems of overall performance damage, easy cracks and decomposition, difficult processing, etc., and achieve high temperature resistance and excellent performance Mechanical properties and the effect of improving the dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

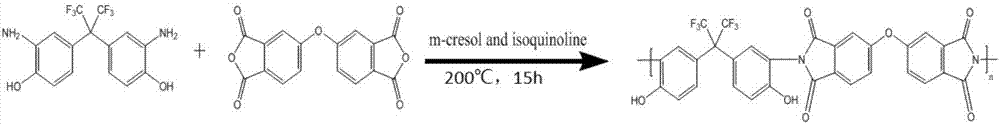

[0036] A method for preparing a composite dielectric film for a film capacitor, the wet method preparation steps of the fluorine-containing polybenzoxazole high-temperature-resistant aromatic heterocyclic film are as follows:

[0037] (1) Synthesis of fluorine-containing phenolic hydroxyl polyimide precursor: weigh 2,2-bis(3-amino-4-hydroxyphenyl)-hexafluoropropane and 4,4'-linked Phenyl ether dianhydride was mixed in the container, adding 20% m-cresol of the raw material quality in the container as a reaction solvent, dripping 6 drops of isoquinoline as a catalyst, stirring at room temperature for 5 hours until fully dissolved; React at 190°C for 15 hours to prepare a viscous solution of a fluorine-containing phenolic hydroxyl polyimide polymer. Precipitate the viscous solution of the fluorine-containing polyimide polymer with methanol as a precipitant and wash it with hot methanol. The final fluorine-containing phenolic hydroxyl polyimide polymer was dried at 100°C for 13 ...

Embodiment 2

[0042] A method for preparing a composite dielectric film for a film capacitor, the wet method preparation steps of the fluorine-containing polybenzoxazole high-temperature-resistant aromatic heterocyclic two-phase composite film reinforced by titanium dioxide nanosheets are as follows:

[0043] (1) Synthesis of fluorine-containing phenolic hydroxyl polyimide precursor: weigh 2,2-bis(3-amino-4-hydroxyphenyl)-hexafluoropropane and 4,4'-linked Phenyl ether dianhydride was mixed in the container, adding 15% m-cresol of the raw material quality in the container as a reaction solvent, dripping 3 drops of isoquinoline as a catalyst, stirring at room temperature for 4 hours until fully dissolved; React at 180°C for 14 hours to prepare a viscous solution of polyimide polymer containing fluorine-containing phenolic hydroxyl groups. Precipitate the viscous solution of the polymer with methanol as a precipitant and wash with hot methanol. The washed phenolic hydroxyl groups The polyimide...

Embodiment 3

[0050] A method for preparing a composite dielectric film for film capacitors, the wet method preparation steps of the fluorine-containing polybenzoxazole high-temperature-resistant aromatic heterocyclic two-phase composite film enhanced by the dielectric enhancement of niobium calcium oxide nanosheets are as follows:

[0051] (1) Synthesis of fluorine-containing phenolic hydroxyl polyimide precursor: weigh 2,2-bis(3-amino-4-hydroxyphenyl)-hexafluoropropane and 4,4'-linked Phenyl ether dianhydride was mixed in the container, adding 15% m-cresol of the raw material quality in the container as a reaction solvent, dripping 3 drops of isoquinoline as a catalyst, stirring at room temperature for 4 hours until fully dissolved; React at 180°C for 14 hours to prepare a viscous solution of polyimide polymer containing fluorine-containing phenolic hydroxyl groups. Precipitate the viscous solution of the polymer with methanol as a precipitant and wash with hot methanol. The washed phenoli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com