A method for preparing porous bioceramic membranes by micro-arc oxidation

A bioceramic membrane and micro-arc oxidation technology, which is applied in tissue regeneration, prosthesis, coating, etc., can solve the problems of micropores and microcracks, poor fracture toughness of micro-arc oxidation ceramic film layer, material waste, etc., to achieve Improve biological performance, facilitate operation, and promote deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

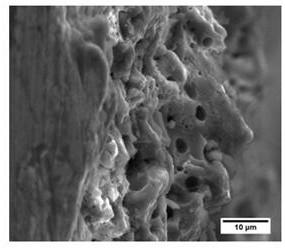

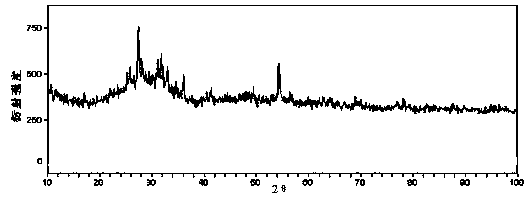

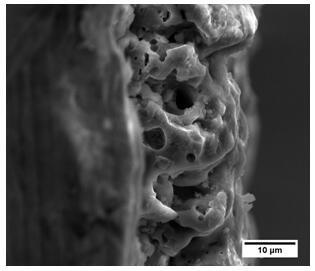

[0033] A method for preparing a porous bioceramic membrane by micro-arc oxidation, specifically comprising the following steps:

[0034] (1) For titanium alloy Ti 6 Al 4 V Surface pretreatment: Cut the titanium alloy into cylindrical titanium material, drill holes above the sample, grind and polish the surface of the titanium alloy until there is no scratch on the surface of the sample, then degrease with acetone, and use 1g / L sodium hydroxide solution alkaline washing and deionized water washing, natural drying after standby;

[0035] (2) Preparation of a gel containing nanoparticles: Mix 10 mL of tetrabutyl phthalate with 20 mL of absolute ethanol and stir to form solution A; then, add 0.14 g of ZrO 2 The nanoparticles were dispersed by adding 20 mL of absolute ethanol, mixed with 2 mL of deionized water, and 2 mL of concentrated nitric acid was added dropwise as a chelating agent to form solution B; then, solution A was added dropwise to the prepared solution B at room t...

Embodiment 2

[0040] A method for preparing a porous bioceramic membrane by micro-arc oxidation, specifically comprising the following steps:

[0041] (1) For titanium alloy Ti 6 Al 4 V Surface pretreatment: Cut the titanium alloy into cylindrical titanium material, drill holes above the sample, grind and polish the surface of the titanium alloy until there is no scratch on the surface of the sample, then degrease with acetone, and use 1g / L sodium hydroxide solution alkaline washing and deionized water washing, natural drying after standby;

[0042] (2) Preparation of a gel containing nanoparticles: Mix 20mL tetrabutyl phthalate with 40mL absolute ethanol and stir to form solution A; then, add 0.5g of anatase TiO 2 The nanoparticles were dispersed by adding 40 mL of absolute ethanol, mixed with 4 mL of deionized water, and 4 mL of concentrated nitric acid was added dropwise as a chelating agent to form solution B; then, solution A was added dropwise to the prepared solution B at room tem...

Embodiment 3

[0047] A method for preparing a porous bioceramic membrane by micro-arc oxidation, specifically comprising the following steps:

[0048] (1) For titanium alloy Ti 6 Al 4 V Surface pretreatment: Cut the titanium alloy into cylindrical titanium material, punch holes on the top of the sample, grind and polish the titanium alloy surface until there are no scratches on the surface of the sample, and then use absolute ethanol to degrease, Wash with 1g / L sodium hydroxide solution and deionized water, and dry naturally for later use;

[0049] (2) Preparation of a gel containing nanoparticles: Mix 20 mL of tetrabutyl phthalate with 40 mL of absolute ethanol and stir to form solution A; then, add 0.5 g of ZrO 2 with 0.5g of rutile TiO 2 Add 40mL of absolute ethanol to the nanoparticles for dispersion and mixing, then mix with 4mL of deionized water, and dropwise add 4mL of concentrated nitric acid as a chelating agent to form solution B; then, add solution A dropwise to the prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com