Double-phase stainless steel bar and preparation method thereof

A technology of duplex stainless steel and steel bar, applied in the field of high-strength stainless steel, can solve the problems of high price, no production data and literature reports of 2205 duplex stainless steel bar, increased production cost of stainless steel bar, etc., to improve yield strength and tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Preferred embodiments of the present invention are specifically described below.

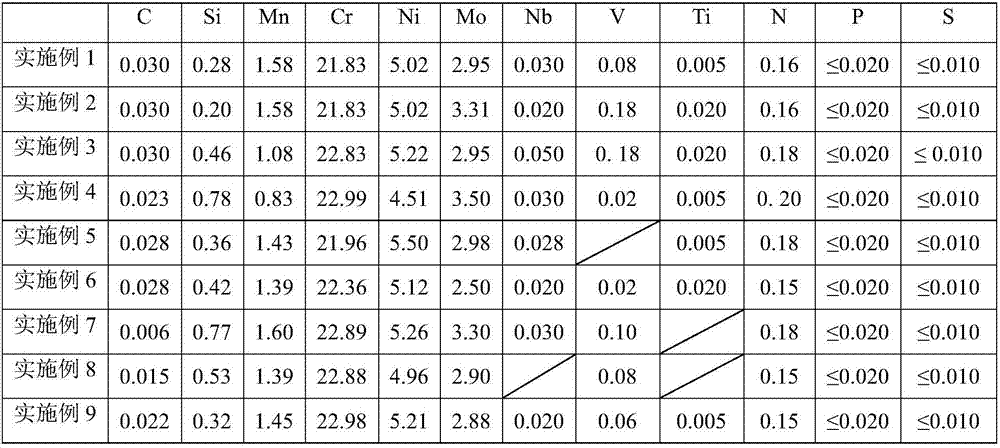

[0031] In the first aspect, the present invention provides a duplex stainless steel bar, which improves the yield strength and tensile strength of the duplex stainless steel bar by adding microalloying elements on the basis of the composition of 2205 stainless steel. The alloy composition of the duplex stainless steel bar consists of The mass percentages are: C≤0.03%, Si 0.20%~0.80%, Mn 0.80%~1.60%, Cr21.00%~23.00%, Ni 4.50%~5.50%, Mo 2.50%~3.50%, Nb 0~0.05 %, V 0-0.16%, Ti 0-0.02%, N 0.15%-0.20%, P≤0.020%, S≤0.010%, and the balance is Fe and unavoidable impurity elements.

[0032] Wherein, the so-called microalloying elements refer to one or more of Nb, V and Ti. It should be noted that since the design idea of the present invention is to increase the yield strength and tensile strength of the solution-treated duplex stainless steel bar by adding microalloy elements, therefore, there ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com