Preparation method and application of tetracycline-polluted water body restoring material

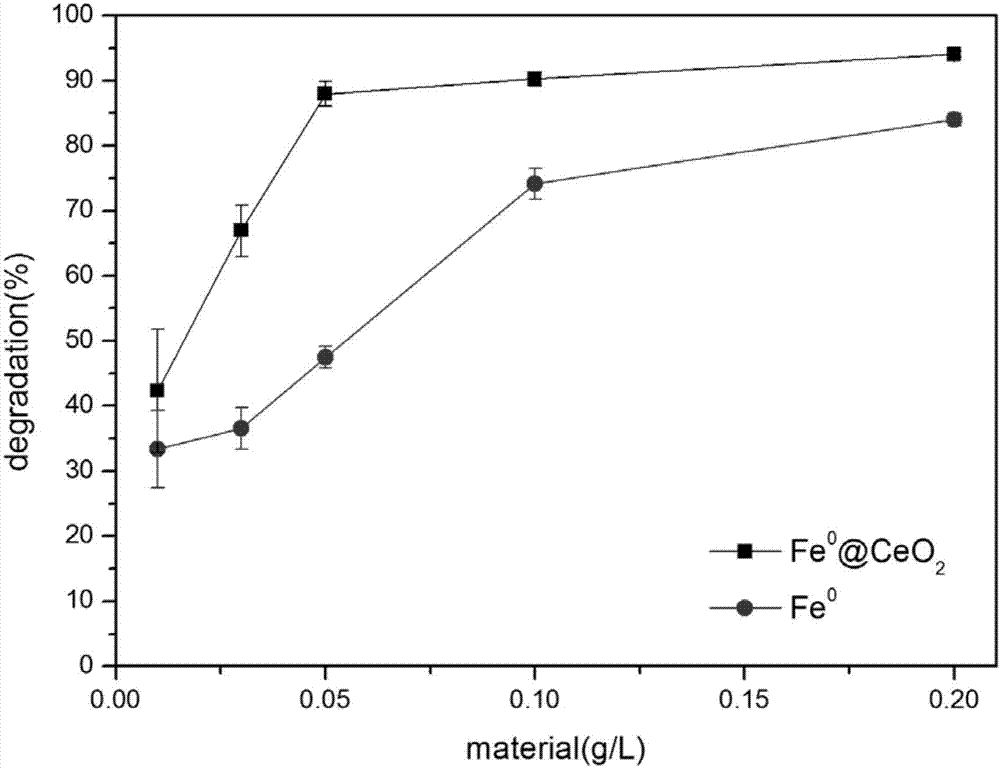

A technology of ethanol aqueous solution and nano-cerium dioxide, which is applied in nanotechnology for materials and surface science, water pollutants, water/sewage treatment, etc., can solve the problems of reducing the reduction and degradation efficiency of nano-zero-valent iron, and achieve easy Promote the use, reduce agglomeration, and improve the removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A preparation method of nano cerium dioxide, comprising the following steps:

[0035] 1) adding cerium nitrate and surfactant into water, mixing and stirring to obtain mixed solution A;

[0036] 2) Add the ammonium carbonate solution into the mixed solution A, stir to obtain the mixed solution B;

[0037] 3) The mixed solution B is filtered, and the obtained precipitate is washed and dried, then calcined and ground into powder to obtain nano ceria.

[0038] Further, step 3) of the preparation method of nano-cerium oxide is specifically as follows: the mixed solution B is filtered and separated, and the white colloid is obtained and washed with ultrapure water and ethanol for 3 times to obtain the white colloid A, and the obtained precipitate after drying is put into Calcined in a muffle furnace and ground into powder to obtain nano ceria.

[0039] Preferably, in step 1) of the method for preparing nano ceria, the mass ratio of cerium nitrate, surfactant and water is (...

preparation example

[0055] A preparation method of nano cerium dioxide particles:

[0056] (1) Add 0.1mol / L cerium nitrate hexahydrate and 4g / L PEG 4000 to 100ml ultrapure water, stir and mix;

[0057] (2) 150ml of 0.1mol / L (NH 4 ) 2 CO 3 The aqueous solution was added to the solution described in step (1), and stirred at 45°C for 15 minutes, filtered and washed several times to obtain white colloidal cerium carbonate;

[0058] (3) Put the white colloid in a drying oven and dry it at 80°C for 8 hours;

[0059] (4) Put the dried white colloid into a muffle furnace, heat up to 500°C at 20°C / min, and roast for 4h. After the temperature of the muffle furnace drops to room temperature, take out the yellow solid and grind it into powder to obtain nanometer 2 Ceria.

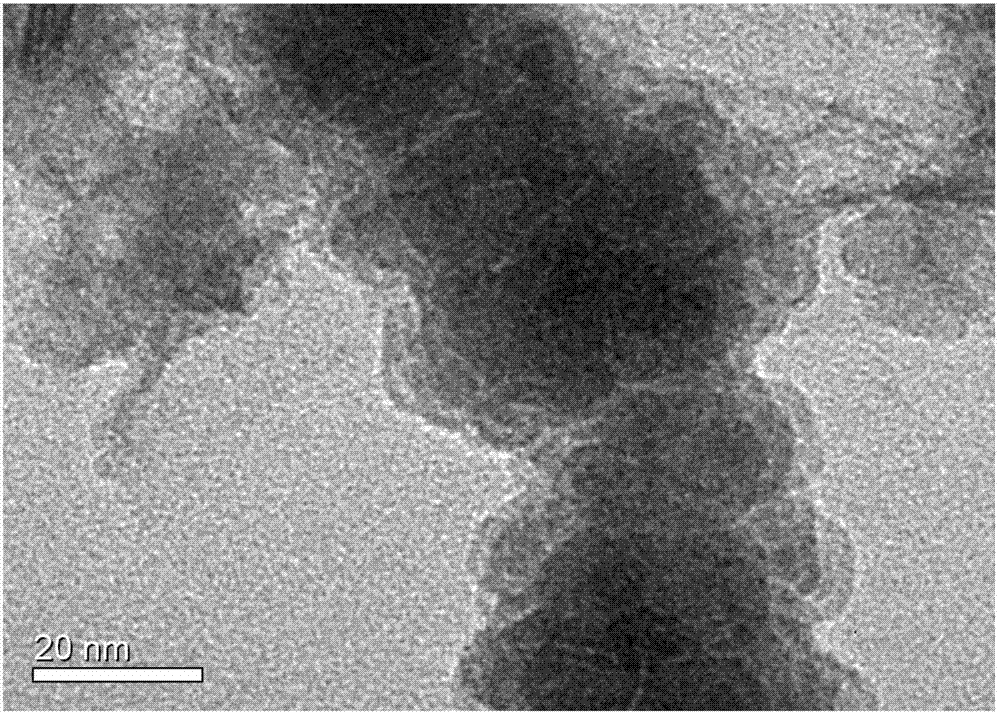

[0060] A nano Fe 0 @CeO 2 The preparation method of particle, the step is:

[0061] (1) Add 0.023mol / L nano-cerium dioxide, 0.05mol / L ferrous sulfate hexahydrate, 4g / LPVP prepared above in 100ml30%v / v ethanol aqueous solution; to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com