Thermal conduction coating material, thermal conduction coating, and composite heat dissipation film

A thermally conductive coating and thermally conductive coating technology, used in coatings, polyurea/polyurethane coatings, film/flaky adhesives, etc., can solve the problem of product heat dissipation performance decline, graphite sheet surface fragile, short circuit of electronic products, etc. problems, to achieve the effect of improving thermal conductivity and insulation, good thermal conductivity, and high thermal emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

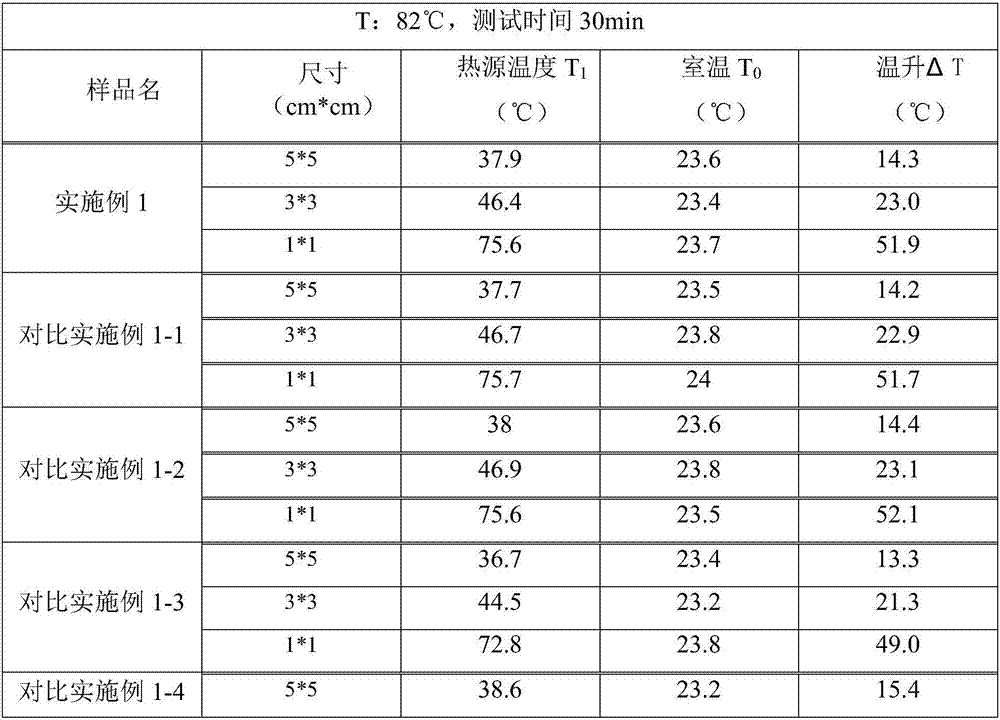

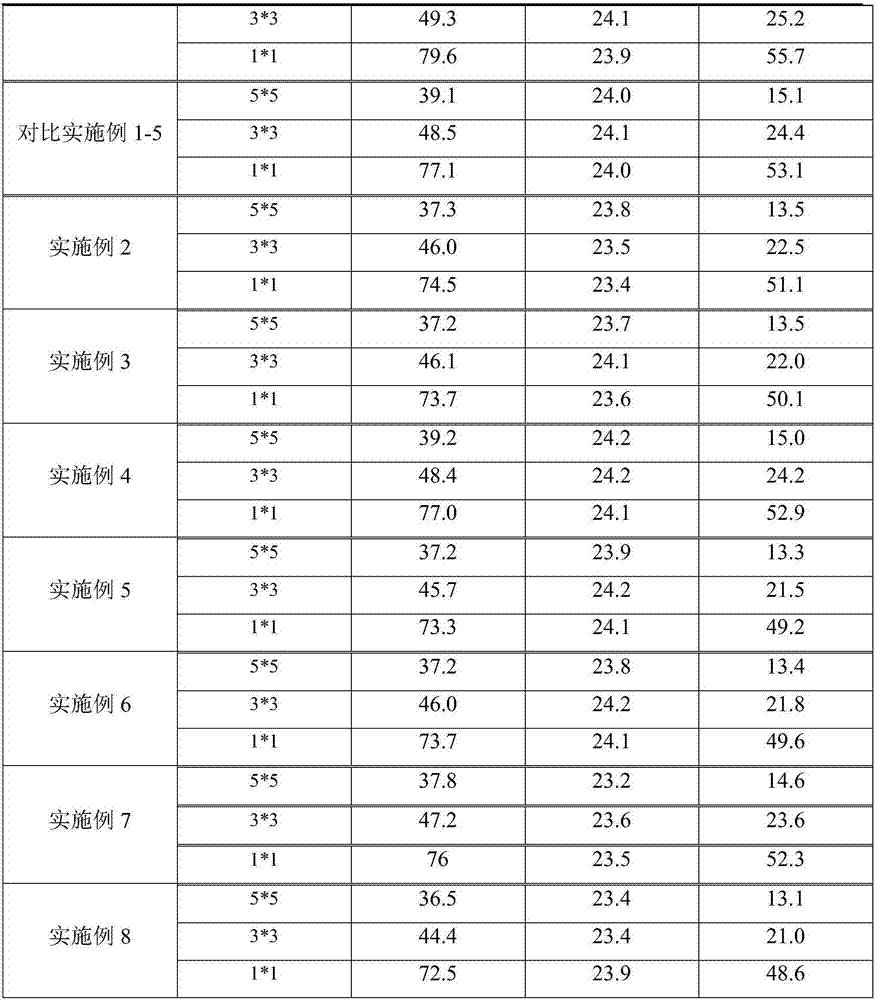

Examples

Embodiment 1

[0055] Thermally conductive coating formula: 70 parts of difunctional aliphatic PUA oligomer, 5 parts of ethoxyethoxyethyl acrylate, 10 parts of diethylene glycol diacrylate, 8 parts of 1-hydroxycyclohexyl phenyl ketone Parts, 5 parts of boron nitride (average particle size 200nm), 1 part of KH-550, 1 part of TDL-ND2 special dispersant for nano-powder.

[0056] Composite heat dissipation film structure: 10μm thermal conductive coating + 25μm graphite sheet + 20μm double-sided adhesive.

[0057] Preparation method of composite heat dissipation film:

[0058] (1) Preparation of thermally conductive coating:

[0059] a. Nano-powder dispersion: 5 parts of boron nitride (average particle size 200nm), 70 parts of bifunctional aliphatic PUA oligomer, 1 part of TDL-ND2 special dispersant for nano-powder, 1 part of KH-550 Add one portion to the mixing cup in turn, stir in the planetary mixer at a rate of 1600rpm for 150s, repeat the stirring 10 times, and remove the air bubbles; Per...

Embodiment 2

[0078] 70 parts of difunctional aliphatic PUA oligomer, 5 parts of ethoxyethoxyethyl acrylate, 10 parts of diethylene glycol diacrylate, 8 parts of 1-hydroxycyclohexyl phenyl ketone, nitrogenated 2.5 parts of boron (average particle size 200nm), 2.5 parts of silicon carbide (average particle size 20nm), 1 part of KH-550, 1 part of TDL-ND2 special dispersant for nano powder.

[0079] The structure and preparation method of the composite heat dissipation film are the same as in Example 1, and the formula is changed to the above formula.

Embodiment 3

[0081] 70 parts of difunctional aliphatic PUA oligomer, 3 parts of ethoxy ethoxy ethyl acrylate, 10 parts of diethylene glycol diacrylate, 10 parts of 1-hydroxycyclohexyl phenyl ketone, nitrogenated 2 parts of boron (average particle size 200nm), 2 parts of silicon carbide (average particle size 20nm), 1 part of alumina (average particle size 800nm), 1 part of KH-550, 1 part of TDL-ND2 special dispersant for nano powder .

[0082] The structure and preparation method of the composite heat dissipation film are the same as in Example 1, and the formula is changed to the above formula.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com