A negative electrode material for double perovskite lithium-ion batteries synthesized by selective crystallization controlled by electric field and its preparation method

A lithium-ion battery and selective crystallization technology, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of complex parent action mechanism, high lithium ion diffusion activation energy, and high synthesis temperature, and achieve accelerated migration ability. and redox reaction rate, improve lithium ion diffusion rate, improve lithium ion conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

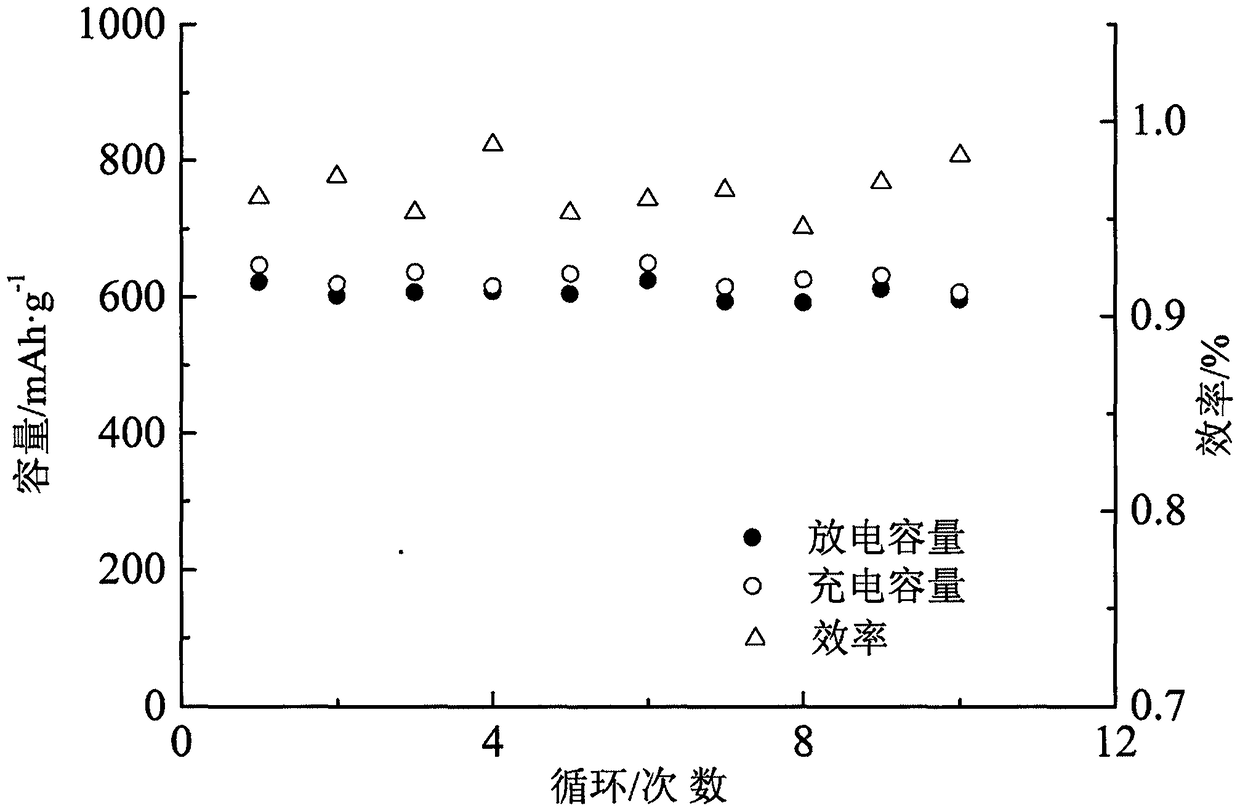

Examples

Embodiment 1

[0017] Embodiment 1: with barium nitrate, lithium nitrate, sodium nitrate, yttrium nitrate hexahydrate, zinc nitrate hexahydrate, manganese nitrate tetrahydrate, niobium pentoxide, cobalt nitrate hexahydrate according to stoichiometric formula Na 0.8 Ba 0.2 Y 0.9 Li 0.1 co 0.9 Zn 0.1 Nb 0.9 mn 0.1 o 6 Put it into a ball mill, the mass ratio of the ball mill and the material is 20:1, and ball mill at a speed of 400 rpm for 20 hours. The ball-milled material is heated up to 900°C at a rate of 10°C / min in a tube furnace, and then a DC voltage of 900V is applied to both ends of the tube furnace. Cool the furnace to 30°C; grind the cooled material in a mortar for 12 minutes, and immerse it in a saturated solution of lithium metaborate at a constant temperature of 30°C under constant stirring at a speed of 1200 rpm with a polytetrafluoroethylene stirring paddle. The mass ratio of the immersed cooled material was 10:1. After stirring for 9 minutes, the constant temperature wa...

Embodiment 2

[0018] Embodiment 2: with barium nitrate, lithium nitrate, sodium nitrate, yttrium nitrate hexahydrate, zinc nitrate hexahydrate, manganese nitrate tetrahydrate, niobium pentoxide, cobalt nitrate hexahydrate according to stoichiometric formula Na 0.8 Ba 0.2 Y 0.9 Li 0.1 co 0.9 Zn 0.1 Nb 0.9 mn 0.1 o 6 Put into the ball mill, the mass ratio of the ball mill and the material is 20:1, and ball mill for 15 hours at a speed of 400 rev / min. The ball-milled material is heated to 900°C at a rate of 8°C / min in a tube furnace, and then a DC voltage of 900V is applied to both ends of the tube furnace. Cool the furnace to 30°C; grind the cooled material in a mortar for 12 minutes, and immerse it in a saturated solution of lithium metaborate at a constant temperature of 30°C under constant stirring at a speed of 1000 rpm with a polytetrafluoroethylene stirring paddle. The mass ratio of the immersed cooled material was 10:1. After stirring for 7 minutes, the constant temperature was...

Embodiment 3

[0019] Embodiment 3: with barium nitrate, lithium nitrate, sodium nitrate, yttrium nitrate hexahydrate, zinc nitrate hexahydrate, manganese nitrate tetrahydrate, niobium pentoxide, cobalt nitrate hexahydrate according to stoichiometric formula Na 0.8 Ba 0.2 Y 0.9 Li 0.1 co 0.9 Zn 0.1 Nb 0.9 mn 0.1 o 6 Put it into a ball mill, the mass ratio of the ball mill to the material is 20:1, and ball mill for 10 hours at a speed of 200 rpm. The ball-milled material is heated to 800°C at a rate of 2°C / min in a tube furnace, and then a DC voltage of 600V is applied to both ends of the tube furnace. Cool the furnace to 30°C; grind the cooled material in a mortar for 6 minutes, and immerse it in a saturated solution of lithium metaborate at a constant temperature of 30°C under constant stirring at a speed of 900 rpm with a polytetrafluoroethylene stirring paddle. The mass ratio of the mass to the immersed cooled material was 10:1. After stirring for 5 minutes, the constant temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com