A method for preparing a large-area surface-enhanced Raman scattering substrate

A surface-enhanced Raman and large-area technology, applied in Raman scattering, material excitation analysis, instruments, etc., to achieve simple operation, high surface-enhanced Raman scattering effect, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

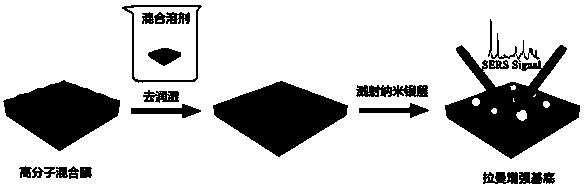

[0024] Example 1: A method for preparing a large-area surface-enhanced Raman scattering substrate. The SERS substrate that can be prepared by a simple method can reach an area of 3.5 cm×3.5 cm. The specific method includes the following steps:

[0025] 1) Polystyrene powder (48 kg / mol, dispersity 1.02) is dissolved in toluene, and a mixed solution of 2 mg / ml is prepared. Cut the circular single crystal silicon wafer into square silicon wafers with a size of 3.5cm×3.5cm with a glass knife; 2 SO 4 , 30%H 2 o 2 and deionized water according to the volume ratio of 100 / 35 / 15 in a certain volume of cleaning solution, boiled at 80 ℃ for 30 minutes; then, rinsed with deionized water, put it into a plastic beaker, and added 20% hydrogen fluoride A mixed solution of acid and deionized water, the volume ratio is 1:1; use hydrofluoric acid to remove the oxide layer on the silicon substrate; finally, rinse with deionized water, and blow dry with high-purity nitrogen for later use.

...

Embodiment 2

[0033] Example 2: A method for preparing a large-area surface-enhanced Raman scattering substrate. The area of the SERS substrate that can be prepared by a simple method can reach 3.5cm×3.5cm. The specific method includes the following steps:

[0034] 1) Polymethyl methacrylate powder (molecular weight: 50 kg / mol, dispersion: 1.1) is dissolved in toluene, and a mixed solution of 2 mg / ml is prepared. Cut the circular monocrystalline silicon wafer into square silicon wafers with a size of 3.5cm×3.5cm with a glass knife; place the cut silicon wafers in a 80% H 2 SO 4 , 30%H 2 o 2 and deionized water according to the volume ratio of 100 / 35 / 15 in a certain volume of cleaning solution, boiled at 80 ℃ for 30 minutes; then, rinsed with deionized water, put it into a plastic beaker, and added 20% hydrogen fluoride A mixed solution of acid and deionized water, the volume ratio is 1:1; use hydrofluoric acid to remove the oxide layer on the silicon substrate; finally, rinse with dei...

Embodiment 3

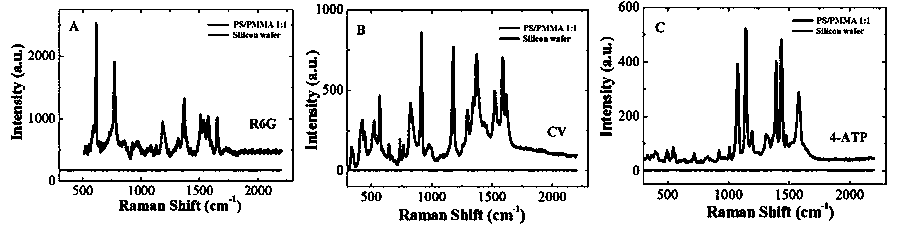

[0042] Example 3: A method for preparing a large-area surface-enhanced Raman scattering substrate. The area of the SERS substrate that can be prepared by a simple method can reach 3.5cm×3.5cm. The specific method includes the following steps:

[0043] 1) Polymethyl methacrylate powder (molecular weight 50 kg / mol, dispersity 1.1) and polystyrene powder (48kg / mol, dispersity 1.02) are mixed and dissolved in toluene at a mass ratio of 2:8, and the configuration is 2 mg / mol ml of mixed solution. Cut the circular monocrystalline silicon wafer into square silicon wafers with a size of 3.5cm×3.5cm with a glass knife; place the cut silicon wafers in a 80% H 2 SO 4 , 30%H 2 o 2 and deionized water according to the volume ratio of 100 / 35 / 15 in a certain volume of cleaning solution, boiled at 80 ℃ for 30 minutes; then, rinsed with deionized water, put it into a plastic beaker, and added 20% hydrogen fluoride A mixed solution of acid and deionized water, the volume ratio is 1:1; us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com