Manufacturing method of directionally organized ceramic matrix composite spare part

A composite material and manufacturing method technology, which is applied in the field of ceramic parts manufacturing, can solve the problems of brittle fracture and low toughness of ceramics, and achieve the effect of good surface quality and high manufacturing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

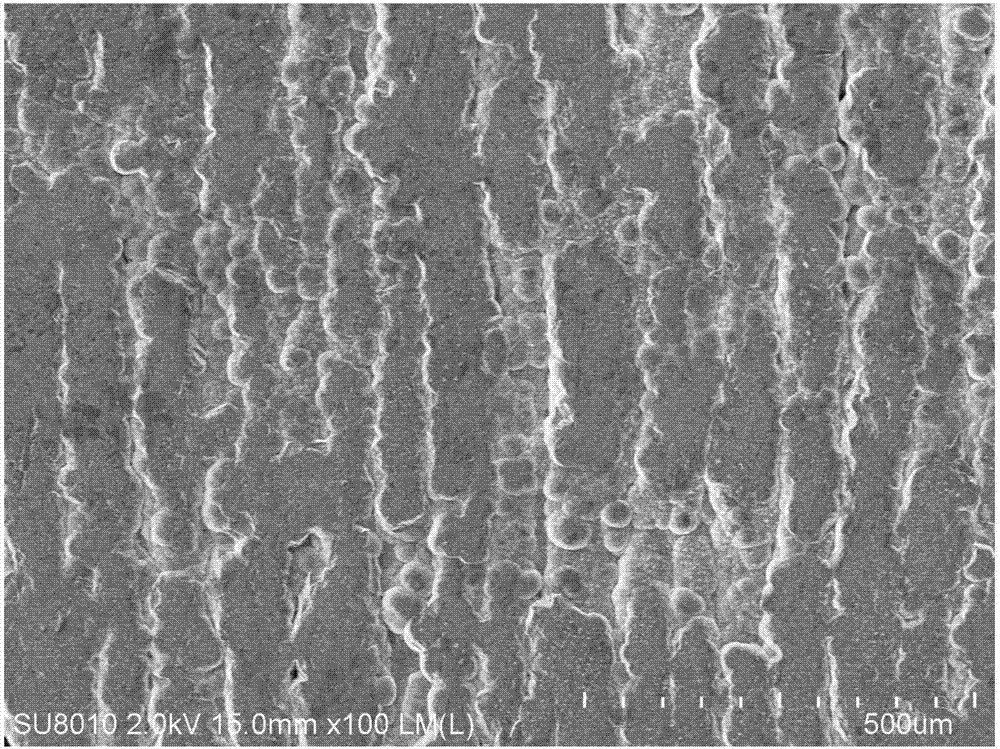

Image

Examples

Embodiment 1

[0057] 1) Use UG 3D modeling software to design the 3D model of the part, and output the STL file. Use the rapid prototyping post-processing software Magics to add the necessary support structure to the model, and slice and layer. Import the processed data files into the shell of the parts manufactured by the SPS600B photocuring molding equipment. The molding process parameters are set as follows: UV beam power is 250mW, filling scanning speed is 4500.00mm / s, filling vector spacing is 0.10mm, supporting scanning speed is 1200.00mm / s, jumping speed is 1200.00mm / s, contour scanning speed is 4000.00mm / s, The layer thickness is 70-100μm, the spot compensation diameter is 150μm, and the lifting speed of the worktable is 3.00mm / s. After processing, clean with industrial alcohol to remove the liquid residual resin material on the surface and remove the support, put it into an ultraviolet curing box for further curing, and obtain a resin mold with a layered structure inside.

[0058...

Embodiment 2

[0065] 1) Use UG 3D modeling software to design the 3D model of the part, and then make the resin shell of the part through SLA light curing molding technology.

[0066] 2) Mix the organic monomer (acrylamide AM) and the crosslinking agent (N,N'-methylenebisacrylamide MBAM) according to the mass ratio of 5:1, and then dissolve them in deionized water at room temperature to prepare A water-based premix with a mass fraction of 15%. Slowly add a mixture of micron-sized silicon nitride and boron carbide ceramic powders and short fibers into the dispersed premix to obtain a ceramic slurry with a solid phase content of 20%, in which the short fibers are a mixture of silicon carbide fibers and alumina fibers , and the content is 10% of the total mass of the slurry; then add an aqueous solution of 25wt% tetramethylammonium hydroxide as a dispersant, and the amount of the dispersant is 1.5% of the total mass of ceramic powder and short fibers to obtain a premixed slurry material. The...

Embodiment 3

[0073] 1) Use UG 3D modeling software to design the 3D model of the part, and then make the resin shell of the part through SLA light curing molding technology.

[0074] 2) Mix the organic monomer (acrylamide AM) and the cross-linking agent (N,N'-methylenebisacrylamide MBAM) at a mass ratio of 25:1, and then dissolve them in deionized water at room temperature to prepare A water-based premix with a mass fraction of 25%. Slowly add the mixture of micron-sized silicon carbide ceramic powder and short fibers into the dispersed premix to obtain a ceramic slurry with a solid phase content of 30%, wherein the short fibers are silicon carbide fibers, and the content is 15% of the total mass of the slurry. %; Then add 25wt% aqueous solution of tetramethylammonium hydroxide as a dispersant, and the amount of dispersant added is 2% of the total mass of ceramic powder and short fibers to obtain a premixed slurry. Then put the premixed slurry into a mechanical stirrer and stir for 40 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com