Polytetrafluoroethylene/polyimide/nano silicon dioxide self-lubricating material and preparation method thereof

A technology of nano-silica and polytetrafluoroethylene, which is applied in the field of polytetrafluoroethylene/polyimide/nano-silica self-lubricating materials and their preparation, can solve the problem of uneven structure of polytetrafluoroethylene materials, etc. problem, achieve the effect of reducing easy peeling, reducing agglomeration and improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

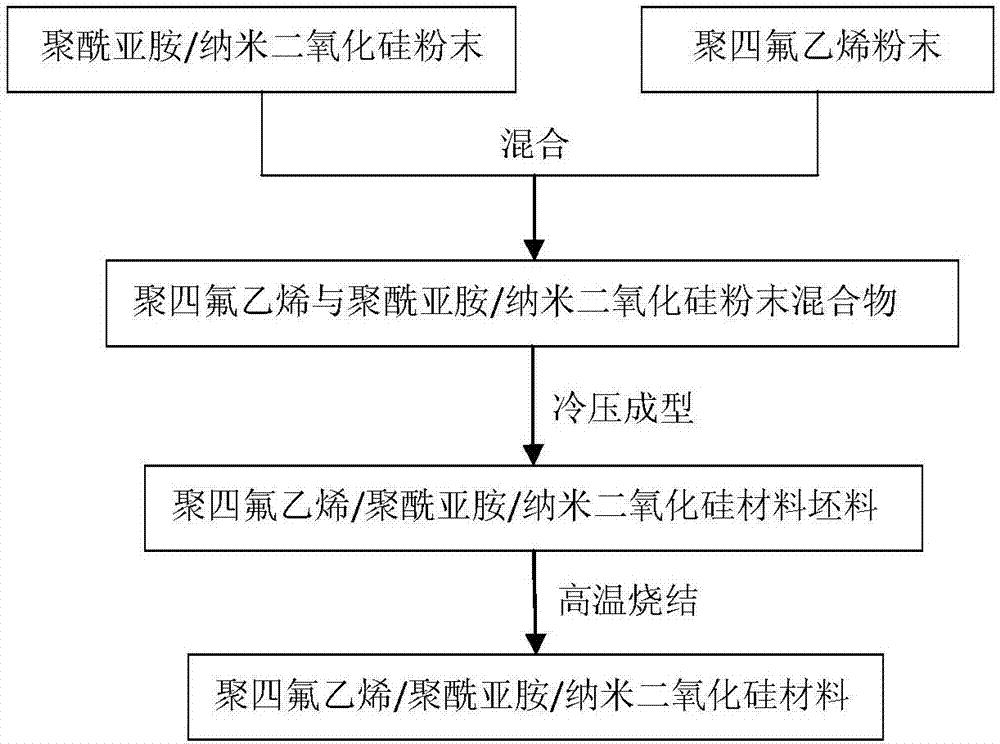

Method used

Image

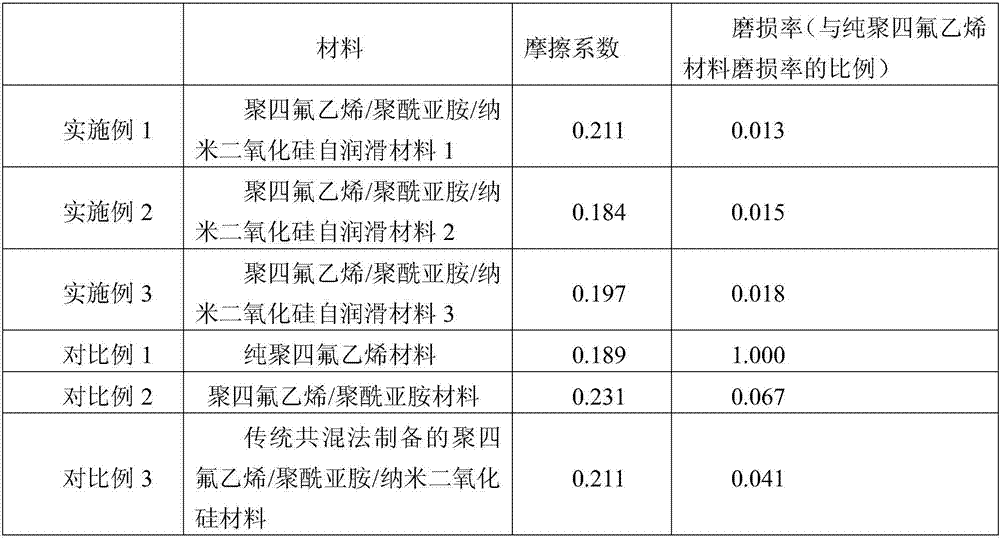

Examples

Embodiment 1

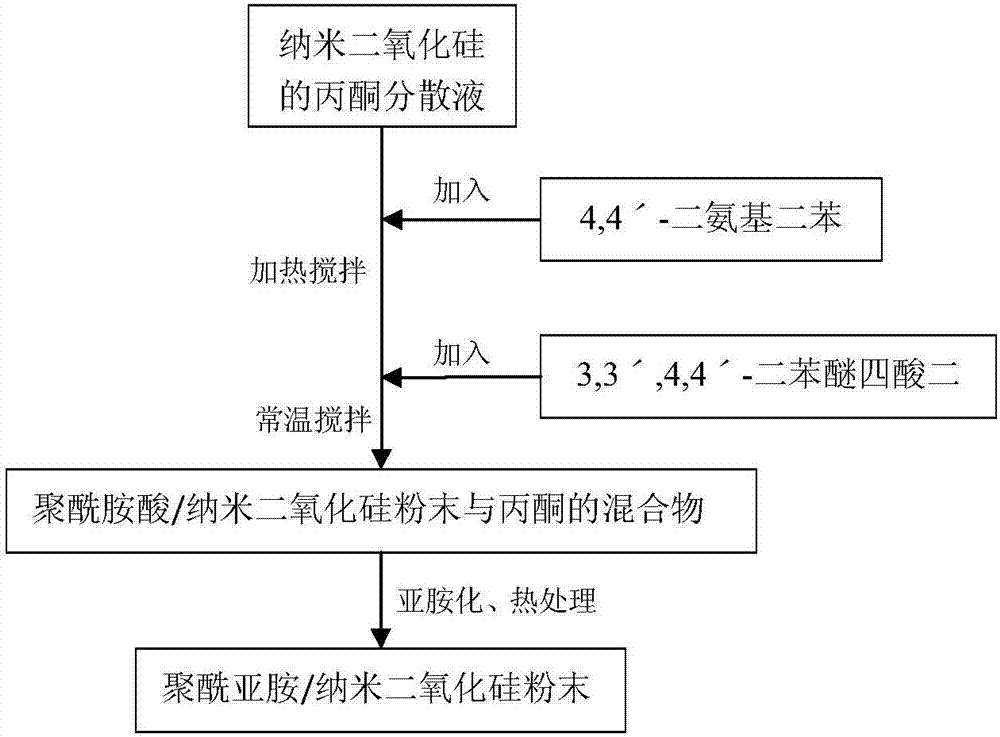

[0030] a: Nano silica dispersion preparation:

[0031] Take 0.14g of nano-silica and put it into acetone, add 0.01g of silane coupling agent (KH-560) dropwise, and after magnetic stirring and ultrasonic oscillation for 20-60min, a stable and evenly dispersed nano-silica dispersion liquid is obtained.

[0032] b. Preparation of polyimide / nano silica powder:

[0033] Add 6.00~6.20g of 4,4′-diaminodiphenyl ether to the nano-silica dispersion, and stir magnetically at 40~50°C for 40~100min, then add 9.00~9.50g of 3,3ˊ,4,4ˊ -Diphenyl ether tetra-acid dianhydride, gradually generate polyamic acid / nanometer silicon dioxide powder, after magnetic stirring at room temperature for 3-6 hours, add triethylamine, acetic anhydride and toluene (the amount added is respectively polyamic acid / nanometer 40-60%, 300-400%, 150-250% of the silica mass), continue to stir for 1-3 hours to complete the imidization reaction, after suction filtration and washing with acetone, dry the product, and At a ...

Embodiment 2

[0039] a: Nano silica dispersion preparation:

[0040] Take 0.42g of nano-silica and put it into acetone, add 0.04g of silane coupling agent (KH-560) dropwise, and after magnetic stirring and ultrasonic oscillation for 20-60min, a stable and evenly dispersed nano-silica dispersion liquid is obtained.

[0041] b. Preparation of polyimide / nano silica powder:

[0042] Add 6.00~6.20g of 4,4′-diaminodiphenyl ether to the nano-silica dispersion, and stir magnetically at 40~50°C for 40~100min, then add 9.00~9.50g of 3,3ˊ,4,4ˊ -Diphenyl ether tetra-acid dianhydride, gradually generate polyamic acid / nanometer silicon dioxide powder, after magnetic stirring at room temperature for 3-6 hours, add triethylamine, acetic anhydride and toluene (the amount added is respectively polyamic acid / nanometer 40-60%, 300-400%, 150-250% of the silica mass), continue to stir for 1-3 hours to complete the imidization reaction, after suction filtration and washing with acetone, dry the product, and At ...

Embodiment 3

[0048] a: Nano silica dispersion preparation:

[0049] Take 0.98g of nano-silica and put it into acetone, add 0.09g of silane coupling agent (KH-560) dropwise, and after magnetic stirring and ultrasonic oscillation for 20-60min, a stable and evenly dispersed nano-silica dispersion liquid is obtained.

[0050] b. Preparation of polyimide / nano silica powder:

[0051] Add 6.00~6.20g of 4,4′-diaminodiphenyl ether to the nano-silica dispersion, and stir magnetically at 40~50°C for 40~100min, then add 9.00~9.50g of 3,3ˊ,4,4ˊ -Diphenyl ether tetra-acid dianhydride, gradually generate polyamic acid / nanometer silicon dioxide powder, after magnetic stirring at room temperature for 3-6 hours, add triethylamine, acetic anhydride and toluene (the amount added is respectively polyamic acid / nanometer 40-60%, 300-400%, 150-250% of the silica mass), continue to stir for 1-3 hours to complete the imidization reaction, after suction filtration and washing with acetone, dry the product, and At ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com