Antistatic coating solution for PET film bottom layer and preparation method and application

An antistatic and coating liquid technology, applied in the direction of conductive coatings, coatings, etc., can solve the problems of large surface resistance, processing and use damage, etc., and achieve the effects of reduced surface resistance, stable performance, and stable system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The film-forming substance is 8.77% of vinylidene chloride-methacrylic acid-methyl acrylate ternary copolymer latex with a solid content of 10wt%,

[0030] Desalinated water 60.91%

[0031] 10wt% sodium hydroxide solution 0.1%

[0032] Conductive polythiophene dispersion PT2 3.07%

[0033] 25wt% silica dispersion 2.63%

[0034] 20wt% resorcinol aqueous solution 4.83%

[0035] 4wt% sodium lauryl sulfate aqueous solution 1.84%

[0036] 2wt% gelatin aqueous solution 0.35%

[0037] Volume fraction 95% ethanol 17.5%

[0038] Weigh the formula at a stirring speed of 100-700r / min and add it to the reactor in sequence according to the order of the materials listed above. After adding one substance, stir continuously for 10-30 minutes before adding the next substance, and all additions are completed. Afterwards, stir continuously for 30-60 minutes, filter, coat on the surface of PET film, and dry under the conditions of wind temperature 115°C and drying time 120s.

Embodiment 2

[0040] The film-forming substance is 8.77% of vinylidene chloride-methacrylic acid-methyl acrylate ternary copolymer latex with a solid content of 10wt%,

[0041] Desalinated water 60.91%

[0042] 10wt% potassium hydroxide solution 0.1%

[0043] Conductive polythiophene dispersion PT2 3.07%

[0044] 30wt% titanium dioxide dispersion 2.63%

[0045] 20wt% resorcinol aqueous solution 4.83%

[0046] Decadecondensed Polyoxyethylene Octylphenol Ether 1.84%

[0047] 2wt% gelatin aqueous solution 0.35%

[0048] Volume fraction 99.5% n-butanol 17.5%

[0049]Weigh the formula at a stirring speed of 100-700r / min and add it to the reactor in sequence according to the order of the materials listed above. After adding one substance, stir continuously for 10-30 minutes before adding the next substance, and all additions are completed. Afterwards, stir continuously for 30-60 minutes, filter, coat on the surface of PET film, and dry under the conditions of wind temperature 115°C and dryi...

Embodiment 3

[0051] The film-forming substance is 8.77% of methacrylic acid-butyl methacrylate-styrene ternary copolymer latex with a solid content of 10wt%,

[0052] Desalinated water 60.91%

[0053] 10wt% sodium hydroxide solution 0.1%

[0054] Conductive polythiophene dispersion PT2 3.07%

[0055] 30wt% silica dispersion 2.63%

[0056] 20wt% phenol aqueous solution 4.83%

[0057] Decadecondensed Polyoxyethylene Octylphenol Ether 1.84%

[0058] 2wt% gelatin aqueous solution 0.35%

[0059] Volume fraction 95% ethanol 17.5%

[0060] Weigh the formula at a stirring speed of 100-700r / min and add it to the reactor in sequence according to the order of the materials listed above. After adding one substance, stir continuously for 10-30 minutes before adding the next substance, and all additions are completed. Afterwards, stir continuously for 30-60 minutes, filter, coat on the surface of PET film, and dry under the conditions of wind temperature 115°C and drying time 120s.

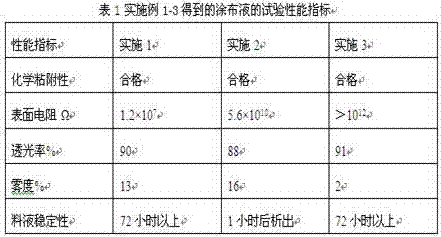

[0061] After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com