High self-sharpening resin binder diamond centerless grinding wheel and manufacturing method thereof

A self-sharpening and bonding agent technology, used in metal processing equipment, grinding/polishing equipment, abrasives, etc., can solve the problems of poor self-sharpening and low durability of grinding wheels, and achieve high self-sharpening, high durability, Good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

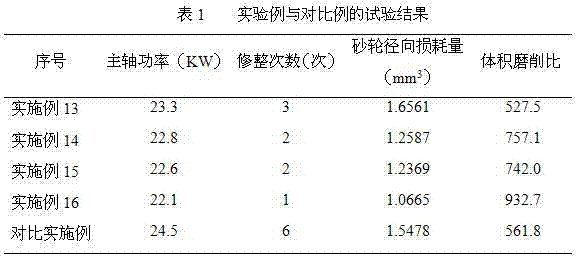

Examples

Embodiment 1

[0027] A high self-sharpening resin bond diamond centerless grinding wheel, including a substrate and an abrasive layer, the abrasive layer is prepared from the following raw materials in parts by weight: 15-25 parts of resin powder, 10-35 parts of micron-sized boron carbide powder, polycrystalline diamond 45-65 parts of abrasive, 1-5 parts of FeCrAl alloy fiber, 1-2 parts of wetting agent.

[0028] The resin powder is imine resin powder or modified imine resin powder.

[0029] The wetting agent is cresol, polyvinyl alcohol or silane coupling agent.

[0030] The FeCrAl alloy fiber has a diameter of 6-10 μm and a length of 0.5 mm.

[0031] As the preparation method of the above-mentioned high self-sharpening resin bond diamond centerless grinding wheel, the specific steps are as follows:

[0032] (1) Mix resin powder, micron-sized boron carbide powder, polycrystalline diamond abrasive, FeCrAl alloy fiber and wetting agent in proportion to obtain a molding material;

[0033] ...

Embodiment 2

[0038] A high self-sharpening resin bond diamond centerless grinding wheel, including a substrate and an abrasive layer, the abrasive layer is prepared from the following raw materials in parts by weight: 15 kg of polyimide resin powder, 10 kg of micron-sized boron carbide powder, polycrystalline diamond abrasive 45 kg, FeCrAl alloy fiber 1 kg, cresol 1 kg.

[0039] The FeCrAl alloy fiber has a diameter of 6 μm and a length of 0.5 mm.

[0040] As the preparation method of the above-mentioned high self-sharpening resin bond diamond centerless grinding wheel, the specific steps are as follows:

[0041] (1) Mix polyimide resin powder, micron-sized boron carbide powder, polycrystalline diamond abrasive, FeCrAl alloy fiber and cresol in proportion to obtain a molding material;

[0042] (2) Put the matrix and the required molding material into the mold, and prepare the grinding wheel blank on the hot press according to a certain molding process. The hot pressing molding temperature...

Embodiment 3

[0047] A high self-sharpening resin bond diamond centerless grinding wheel, including a substrate and an abrasive layer, the abrasive layer is prepared from the following raw materials in parts by weight: 16 kg of bismaleimide resin powder, 12 kg of micron-sized boron carbide powder, polycrystalline Diamond abrasive 47kg, FeCrAl alloy fiber 1.5kg, polyvinyl alcohol 1.1kg.

[0048]The FeCrAl alloy fiber has a diameter of 7 μm and a length of 0.5 mm.

[0049] As the preparation method of the above-mentioned high self-sharpening resin bond diamond centerless grinding wheel, the specific steps are as follows:

[0050] (1) Mix bismaleimide resin powder, micron-sized boron carbide powder, polycrystalline diamond abrasive, FeCrAl alloy fiber and polyvinyl alcohol in proportion to obtain a molding material;

[0051] (2) Put the matrix and the required molding materials into the mold, and prepare the grinding wheel blank on the hot press according to a certain molding process. The hot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com