Preparation method of high-content troxerutin

A high-content, rutin technology, applied in the field of high-content troxerutin preparation, can solve the problems of cumbersome operation, unsuitable for industrialization promotion and application, high cost, and achieves the effect of being widely used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

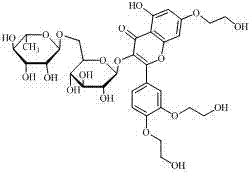

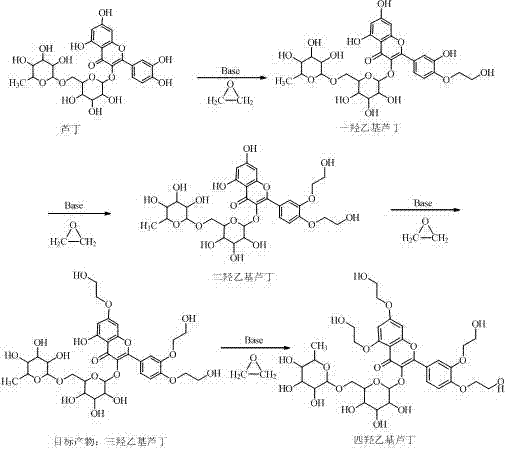

Image

Examples

Embodiment 1

[0025] (1) Add 264 g (6.6 mol) of sodium hydroxide into 30 L of distilled water, stir to dissolve, then add 2 Kg (3.3 mol) of crude rutin, stir at 90 °C until dissolved, add 100 g of diatomaceous earth, and pump while hot Filter to obtain a clear filtrate. The filtrate was adjusted to pH 5.0 with hydrochloric acid. Slowly cool down to room temperature, the cooling time is controlled at 3 h, stand at room temperature for 4 h, filter with suction, filter cake is rinsed with 4L water, yield 95.1%, purity 99.0%;

[0026] (2) Add 200 g of rutin and 10.0 g of natural polymer sodium alginate obtained in (1) into 800 g of anhydrous methanol, then add 80 g of ethylene oxide, seal the autoclave, and start heating and stirring , after heating to 80 °C, heat preservation reaction for 5.0 h, when the proportion of trihydroxyethyl rutin reached 86% as detected by HPLC, the temperature was rapidly lowered to terminate the reaction, the pH value of the reaction solution was adjusted to 5.0 w...

Embodiment 2

[0029] (1) Add 185 g (3.3 mol) of potassium hydroxide to 40 L of distilled water, stir to dissolve, then add 2 Kg (3.3 mol) of crude rutin, stir at 80 °C until dissolved, add 160 g of diatomaceous earth, and heat Suction filtration to obtain a clear filtrate. The filtrate was adjusted to pH 5.0 with hydrochloric acid. Slowly cool down to room temperature, the cooling time is controlled at 3 h, stand at room temperature for 4 h, filter with suction, and rinse the filter cake with 14 L of water. The yield is 95.2%, and the purity is 99.2%;

[0030](2) Add 200 g of rutin and 4.0 g of natural polymer sodium alginate obtained in (1) to 1000 g of anhydrous methanol, then add 80 g of ethylene oxide, seal the autoclave, and start heating and stirring , after heating to 70 °C, heat preservation reaction for 8.0 h, when the proportion of trihydroxyethyl rutin reached 86% as detected by HPLC, the temperature was rapidly lowered to terminate the reaction, hydrochloric acid was added to a...

Embodiment 3

[0033] (1) Add 132 g (3.3 mol) of sodium hydroxide into 50 L of distilled water, stir to dissolve, then add 2 Kg (3.3 mol) of crude rutin, stir at 100 °C until dissolved, add 40 g of diatomaceous earth, and heat Suction filtration to obtain a clear filtrate. The filtrate was adjusted to pH 3.0 with nitric acid. Slowly cool down to room temperature, the cooling time is controlled at 3 h, stand at room temperature for 4 h, suction filter, filter cake is rinsed with 20 L of water, the yield is 94.3%, and the purity is 99.3%;

[0034] (2) Take 200 g of rutin and 8.0 g of natural polymer sodium alginate obtained in (1) and add them to 800 g of anhydrous methanol, then add 100 g of ethylene oxide, seal the autoclave, and start heating and stirring , after heating to 60°C, keep the reaction for 5.5 h, and when the ratio of trihydroxyethyl rutin reaches 86% as detected by HPLC, quickly cool down to terminate the reaction, add hydrochloric acid to adjust the pH value of the reaction s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com