Nanocrystalline rapid quenching rare-earth permanent magnet material, minishing method of grain size of rare-earth permanent magnet material and bonded permanent magnet

A rare earth permanent magnet and grain size technology, which is applied in the direction of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve the problem of intrinsic magnetic properties such as coercive force loss and anisotropy that cannot be compensated for exchange coupling. Contribution, unable to compensate for the loss of coercive force, etc., to achieve the effect of increasing the nucleation rate, increasing the residual magnetization, and increasing the remanence and coercive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

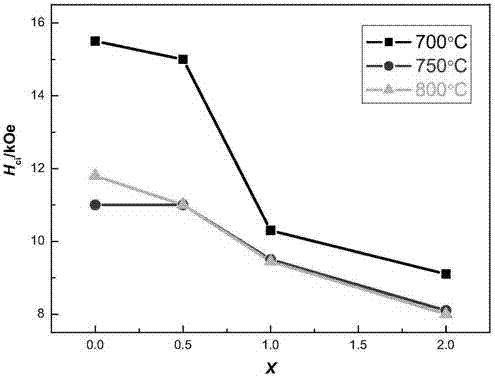

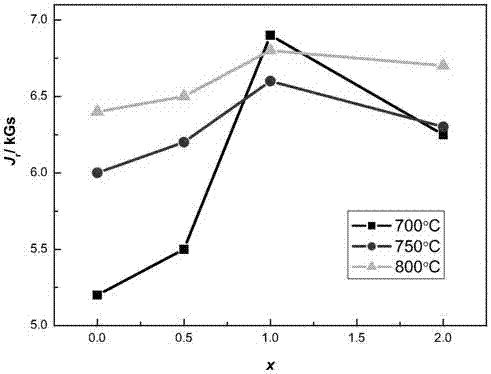

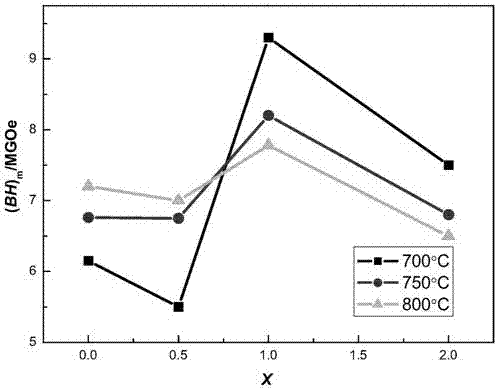

[0027] Prepared by vacuum arc melting, the nominal composition (atomic percentage) is Nd 9-x Y x Fe 72 Ti 2 Zr 2 B 15 Pre-alloyed ingots of (x=0.5, 1.0, 2.0). Grinding the surface of pre-alloyed ingots with different components, performing high-frequency remelting in an argon-protected environment, and then using the pressure difference inside and outside the tube to spray the melt on the high-speed rotating copper roller. Copper roller surface speed V s = 4m / s. The rapid quenching process was carried out under the protection of argon negative pressure. Afterwards, vacuum heat treatment at 600° C. to 800° C. for 10 minutes is carried out on the quenched strip, and then water quenching and quick cooling to obtain a nanocrystalline permanent magnet material.

[0028] Effect of adding alloying elements on remanence: by Figure 2a , Figure 2b , Figure 2c , Figure 2d It can be seen that with the increase of Y content, the fracture microstructure is obviously refined,...

Embodiment 2

[0032] Prepared by vacuum arc melting, the nominal composition (atomic percentage) is Nd 9-x Y x Fe 72 Ti 2 Zr 2 B 15 Pre-alloyed ingots of (x=0.5, 1.0, 2.0). Grinding the surface of pre-alloyed ingots with different components, performing high-frequency remelting in an argon-protected environment, and then using the pressure difference inside and outside the tube to spray the melt on the high-speed rotating copper roller. Copper roller surface speed V s = 6m / s. The rapid quenching process was carried out under the protection of argon negative pressure. Afterwards, the as-quenched alloy is subjected to vacuum heat treatment at 600° C. to 800° C. for 10 minutes, and then water-quenched and rapidly cooled to obtain a nanocrystalline permanent magnet material.

[0033] Effect of adding alloying elements on remanence: by Figure 3b , Figure 3c It can be seen that with the increase of Y content, the remanence of the heat-treated samples shows the characteristics of first...

Embodiment 3

[0038] Prepared by vacuum arc melting, the nominal composition (atomic percentage) is Nd 11.8-x Ho x Fe 81.2 Nb 0.5 Cu 0.5 B 6.0 (x = 0.5, 1.0, 1.5, 2.0, 2.5) pre-alloyed ingots were smelted four times on the reverse side, and the protective gas during smelting was argon. Grind the surface of the pre-alloyed ingot, then put it into a quartz tube, and carry out high-frequency remelting in an argon-protected environment, and then use the pressure difference between the inside and outside of the tube to spray the melt on the high-speed rotating copper roller. Speed V s =28m / s, the quenched alloy is obtained. Afterwards, vacuum heat treatment at 600° C. to 800° C. for 10 minutes is carried out on the quenched strip, and then water quenching and quick cooling to obtain a nanocrystalline permanent magnet material.

[0039] Effect of adding alloying elements on remanence: Figure 4a , Figure 4b , Figure 4c It also shows a similar problem. For different heavy rare earth ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com