Copper and silver co-doped nano-zinc oxide used as photocatalyst, and preparation method of copper and silver co-doped nano-zinc oxide

A nano-zinc oxide, photocatalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of unfavorable industrial production applications, limited photocatalytic activity of ZnO , the problem of high production cost, to achieve the effect of excellent photocatalytic activity, improved photocatalytic efficiency, and low difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

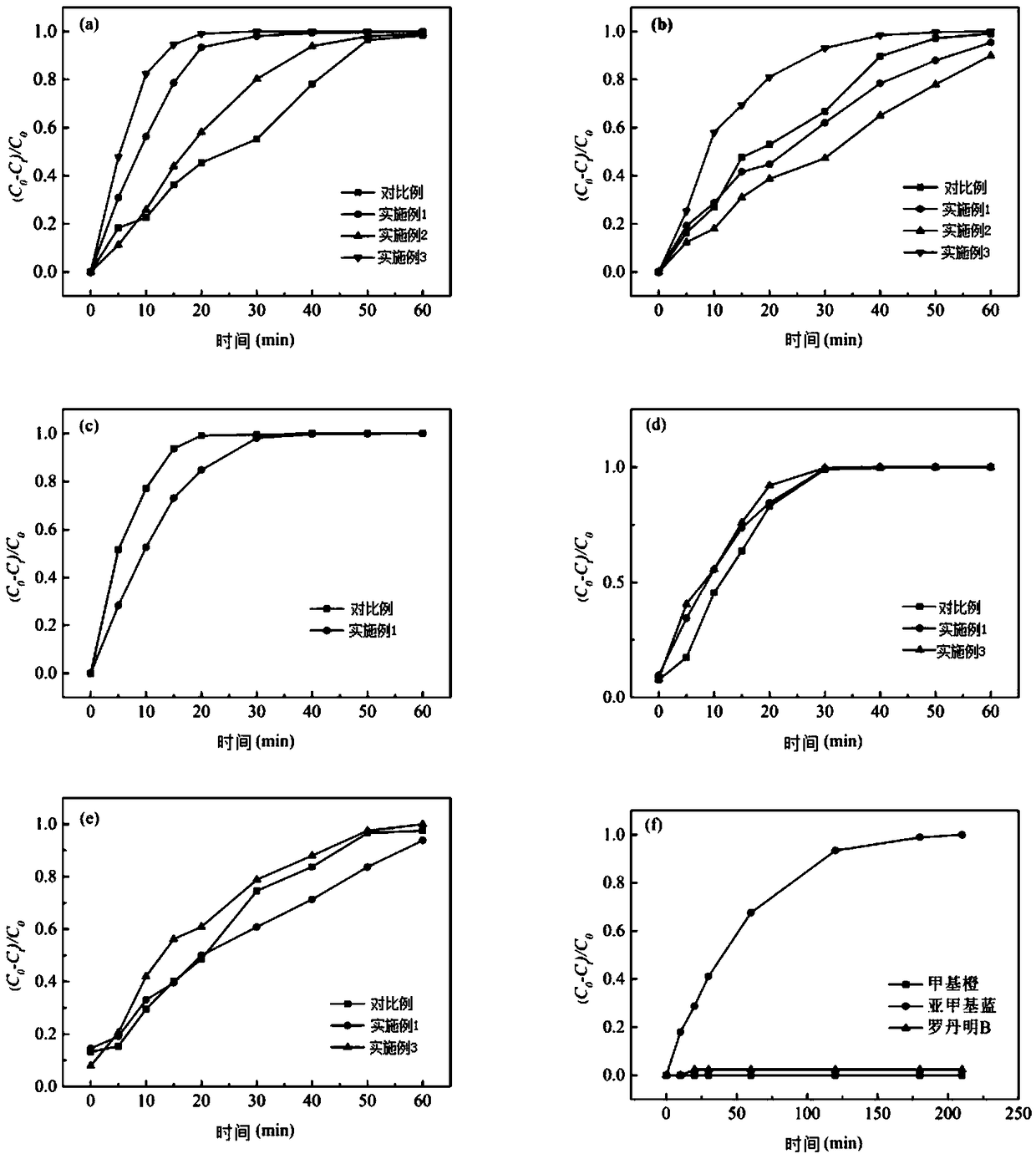

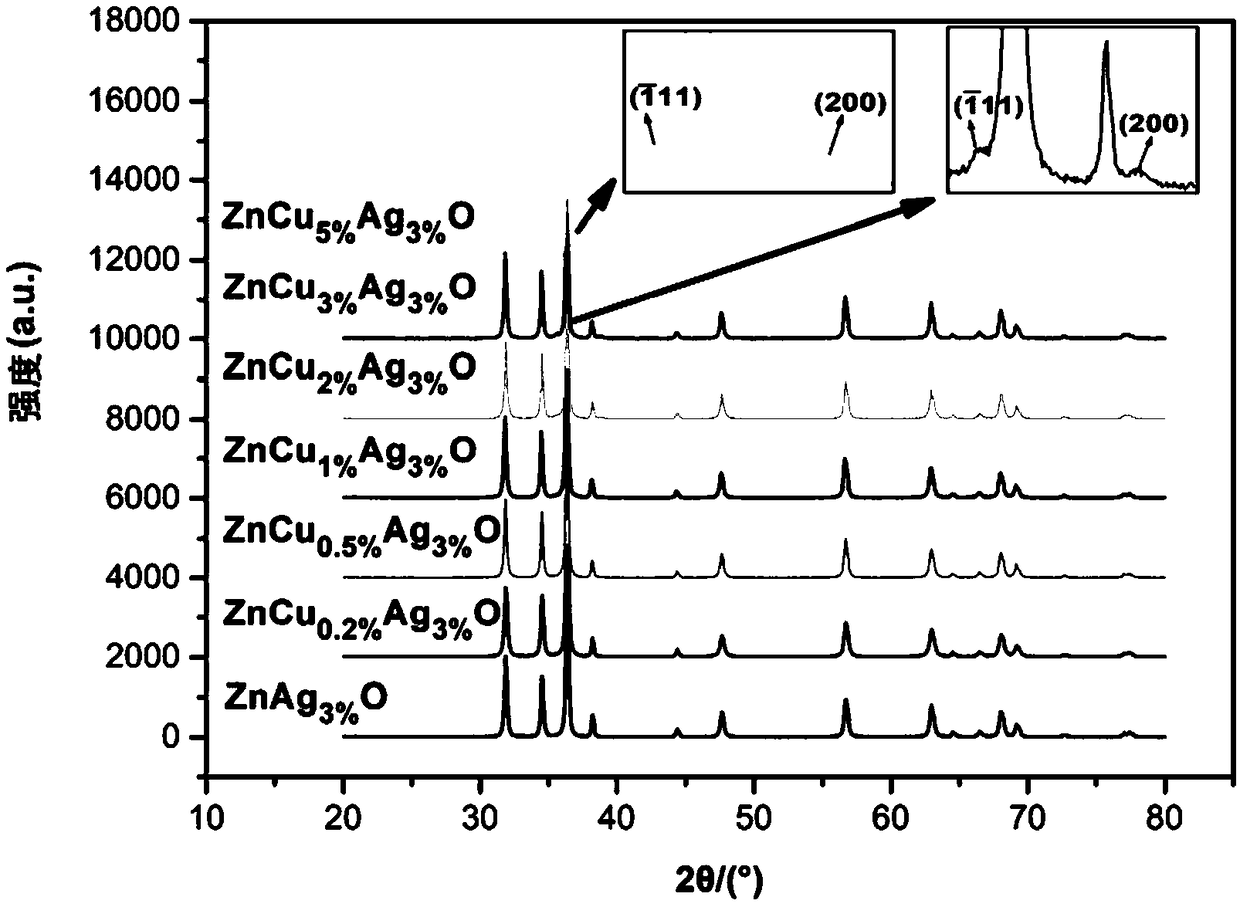

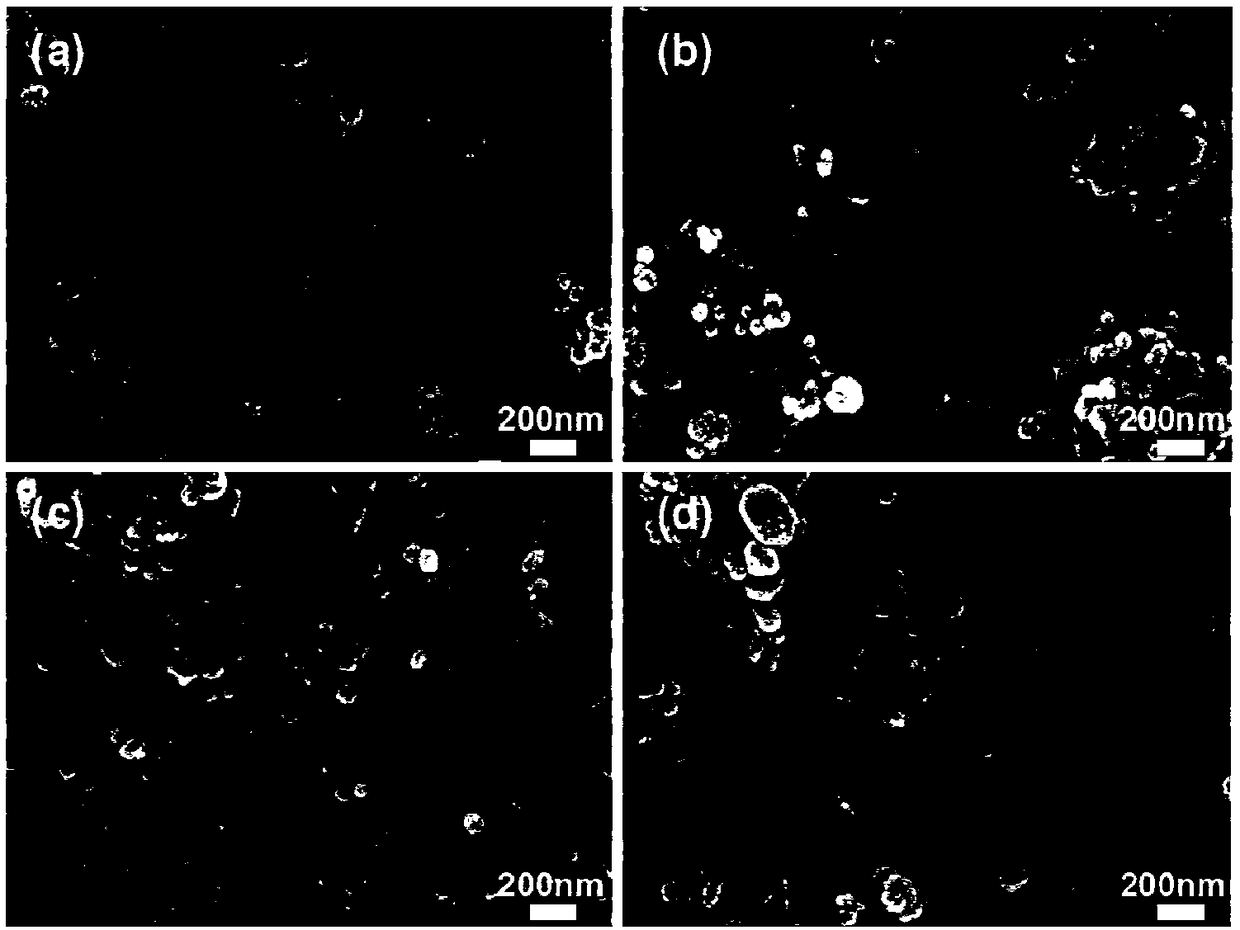

[0029] What this embodiment prepares is the nano-ZnO photocatalyst that Cu, Ag co-doped, and wherein Cu accounts for Cu, Ag and ZnO total substance amount mole percentage is 0.2%, Ag accounts for Cu, Ag and ZnO total substance amount mole percent The percentage is 3%.

[0030] The steps of the nanometer ZnO photocatalyst that this comparative example prepares Cu, Ag co-doped are as follows:

[0031] Under stirring conditions, add 0.01936mol zinc acetate, 0.0006mol silver nitrate, 0.00004mol copper acetate and 2.5mL diethanolamine into 60mL absolute ethanol at room temperature, then continue to stir for 2 hours in a water bath at 57°C until the raw materials are completely dissolved After that, put it in a dark room and let it stand for 44 hours, and then put the obtained solution in an 80°C constant temperature blast drying oven to dry for 10 hours to obtain a wet gel, and then put the wet gel in a muffle furnace sintering furnace at a rate of 2°C / min. The heating rate was rais...

Embodiment 2

[0033] What the present embodiment prepares is the nano-ZnO photocatalyst that Cu, Ag co-doped, and wherein Cu accounts for Cu, Ag and ZnO total substance amount mole percentage is 1%, and Ag accounts for Cu, Ag and ZnO total substance amount mole percent The percentage is 3%.

[0034] The steps of the nanometer ZnO photocatalyst that this comparative example prepares Cu, Ag co-doped are as follows:

[0035] Under stirring conditions, add 0.0192mol zinc acetate, 0.0006mol silver nitrate, 0.0002mol copper acetate and 2.5mL diethanolamine into 60mL absolute ethanol at room temperature, then continue stirring for 2h in a water bath at 60°C until the raw materials are completely dissolved After that, put it in a dark room and let it stand for 48 hours, and then put the obtained solution in a 90°C constant temperature blast drying oven to dry for 8 hours to obtain a wet gel, and then put the wet gel in a muffle furnace sintering furnace at a rate of 1°C / min. The heating rate was r...

Embodiment 3

[0037] What the present embodiment prepares is the nano-ZnO photocatalyst of Cu, Ag co-doped, and wherein Cu accounts for Cu, Ag and ZnO total substance amount mole percentage is 3%, and Ag accounts for Cu, Ag and ZnO total substance amount mole percent The percentage is 3%.

[0038] The steps of the nanometer ZnO photocatalyst that this comparative example prepares Cu, Ag co-doped are as follows:

[0039] Under stirring conditions, add 0.0188mol zinc acetate, 0.0006mol silver nitrate, 0.0006mol copper acetate and 2.5mL diethanolamine into 60mL absolute ethanol at room temperature, then continue stirring for 2 hours in a water bath at 62°C until the raw materials are completely dissolved After that, put it in a dark room and let it stand for 50 hours, and then put the obtained solution in a constant temperature blast drying oven at 85°C and dry it for 9 hours to obtain a wet gel, and then put the wet gel in a muffle furnace sintering furnace at a rate of 2°C / min. The heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com