A tial alloy with ti 2 Diffusion bonding method of alnb alloy

A diffusion joining and alloying technology, applied in welding/welding/cutting items, welding equipment, metal processing equipment, etc., can solve the problems of difficult to control interface structure, complicated diffusion joining process, etc., to eliminate defects such as interface holes and element diffusion. The effect of fast, increased element diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

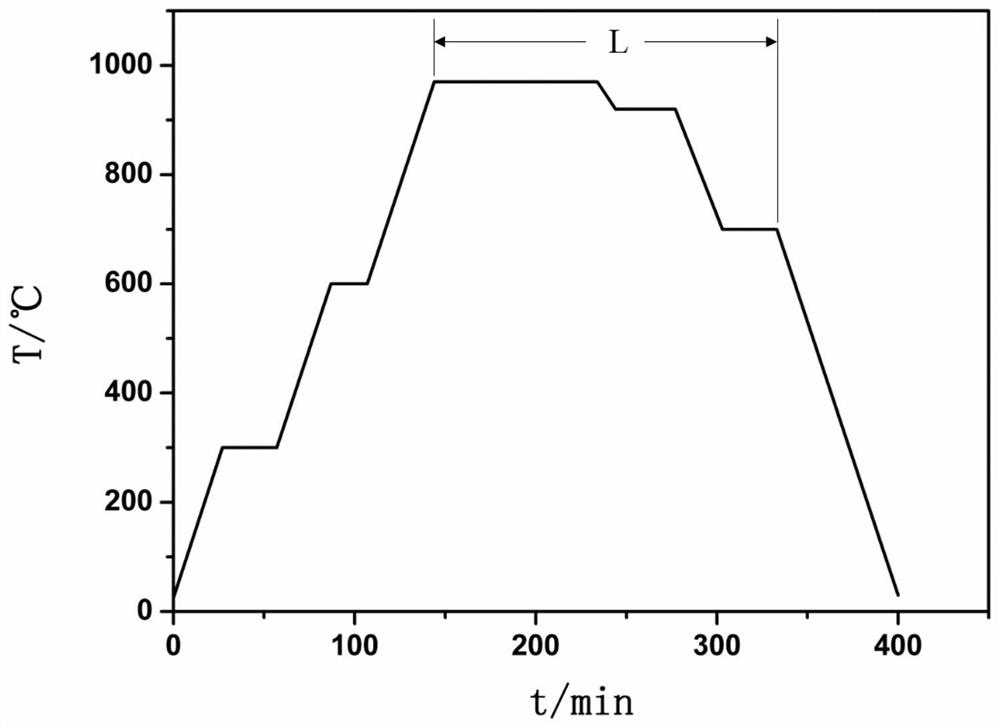

[0030] The concrete process of this embodiment is:

[0031] Step 1: Cut the sample. TiAl alloy and Ti 2 AlNb alloys are processed by wire cutting respectively to obtain the TiAl alloy samples and TiAl alloy samples to be connected according to the design requirements. 2 AlNb alloy samples.

[0032] Step 2: Surface treatment. The resulting TiAl alloy to be joined and Ti 2 The connection surface of the AlNb alloy is finely ground by a grinding machine to eliminate obvious scratches on the surface to be connected, and then mechanically polished with 1.5# diamond grinding and polishing paste to make the surface to be connected show a mirror effect, and then the sample is immersed in absolute ethanol and ultrasonically Degreasing treatment for 5 minutes, and placed in absolute ethanol for storage.

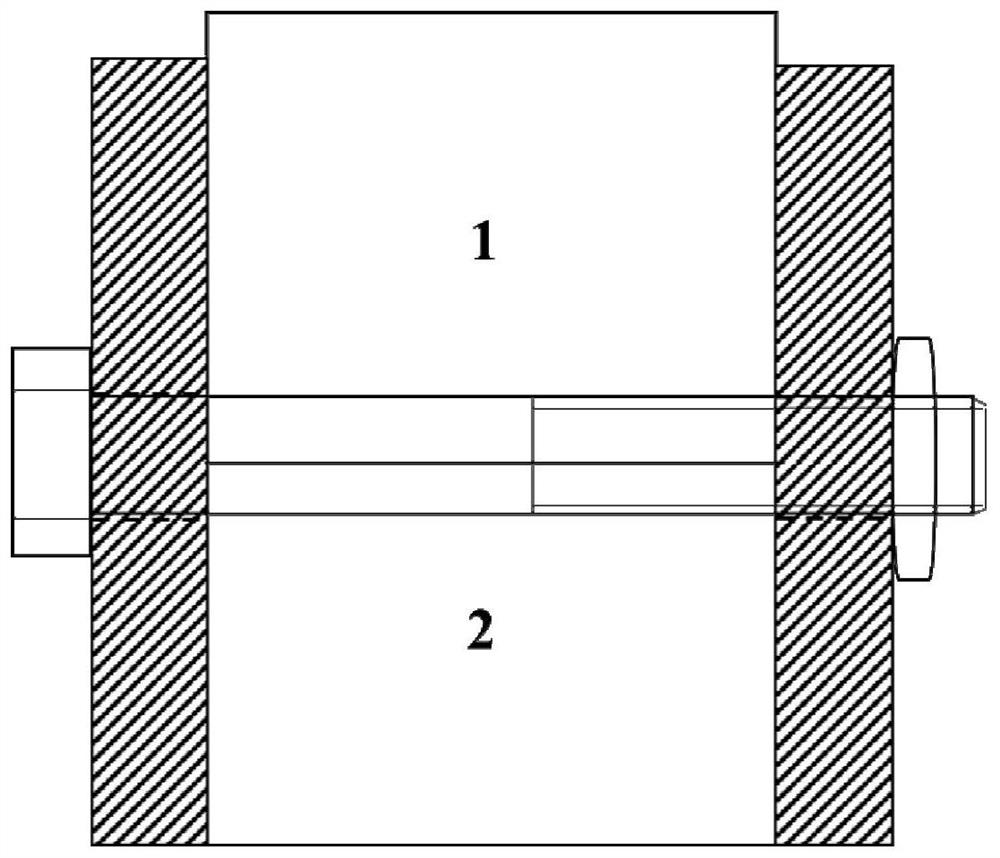

[0033] Step 3: Make the assembly parts. Apply solder stopper to the part of the fixture close to the edge of the welded sample. Put the TiAl alloy in the jig, and then put the Ti...

Embodiment 2

[0038] The concrete process of this embodiment is:

[0039] Step 1: Cut the sample. TiAl alloy and Ti 2 AlNb alloys are processed by wire cutting respectively to obtain the TiAl alloy samples and TiAl alloy samples to be connected according to the design requirements. 2 AlNb alloy samples.

[0040] Step 2: Surface treatment. The resulting TiAl alloy to be joined and Ti 2 The connection surface of the AlNb alloy is finely ground by a grinding machine to eliminate obvious scratches on the surface to be connected, and then mechanically polished with 1.5# diamond grinding and polishing paste to make the surface to be connected show a mirror effect, and then the sample is immersed in absolute ethanol and ultrasonically Degreasing treatment for 5 minutes, and placed in absolute ethanol for storage.

[0041] Step 3: Make the assembly parts. Apply solder stopper to the part of the fixture close to the edge of the welded sample. Put the TiAl alloy in the jig, and then put the Ti...

Embodiment 3

[0046] The concrete process of this embodiment is:

[0047] Step 1: Cut the sample. TiAl alloy and Ti 2 AlNb alloys are processed by wire cutting respectively to obtain the TiAl alloy samples and TiAl alloy samples to be connected according to the design requirements. 2 AlNb alloy samples.

[0048] Step 2: Surface treatment. The resulting TiAl alloy to be joined and Ti 2 The connection surface of the AlNb alloy is finely ground by a grinding machine to eliminate obvious scratches on the surface to be connected, and then mechanically polished with 1.5# diamond grinding and polishing paste to make the surface to be connected show a mirror effect, and then the sample is immersed in absolute ethanol and ultrasonically Degreasing treatment for 5 minutes, and placed in absolute ethanol for storage.

[0049] Step 3: Make the assembly parts. Apply solder stopper to the part of the fixture close to the edge of the welded sample. Put the TiAl alloy in the jig, and then put the Ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com