Superhydrophobic coating spray for material surface protection and preparation and use methods thereof

A technology of super-hydrophobic coating and hydrophobic agent, applied in the direction of coating, can solve the problems of weak adhesion of super-hydrophobic coating, short protection time, complicated preparation process, etc., and achieve low cost of materials and preparation equipment and suitable temperature range. The effect of wide and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

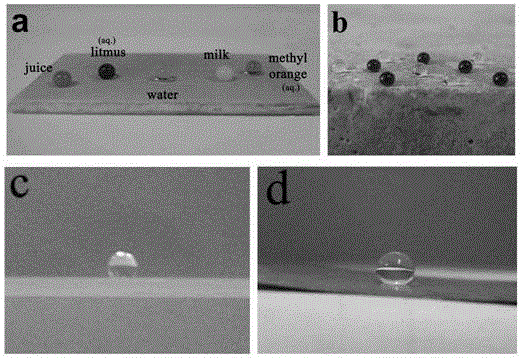

Image

Examples

Embodiment 1

[0038] A superhydrophobic coating spray for aluminum surface protection and its preparation and use method, the material is composed of nano-alumina with a particle size of 30nm, talcum powder of 8μm, methyltriethoxysilane and acetone, and its preparation The process and method are as follows:

[0039] Add 0.3 parts of nano-alumina and 0.3 parts of talc powder in a weight ratio to 84.4 parts of acetone, ultrasonically treat for 8 minutes, and then disperse with a high-speed homogenizer for 10 minutes. Then, the pH was adjusted to 5 with nitric acid, and 15 parts of methyltriethoxysilane was added dropwise at a constant speed under magnetic stirring, and the dropping time was controlled at 20 minutes, followed by reaction under ultrasonic for 2 hours to prepare a superhydrophobic coating spray.

[0040]The prepared superhydrophobic spray was used to protect the surface of 6063 aluminum alloy plate. Before spraying the protective agent, first clean the surface of the aluminum a...

Embodiment 2

[0042] A super-hydrophobic coating spray for concrete surface protection and its preparation and use method. The material is composed of nano-silica with a particle size of 60nm, talcum powder with a particle size of 12μm, octadecyltrimethoxysilane and ethanol. The preparation process and method are as follows:

[0043] Add 0.5 parts of nano-silica and 0.2 parts of talc powder into 87.3 parts of ethanol, ultrasonically treat for 10 minutes, and then disperse with a high-speed homogenizer for 8 minutes. Then, adjust the pH to 6 with nitric acid, add 12 parts of octadecyltrimethoxysilane dropwise at a constant speed under magnetic stirring, and the dropping time is controlled at 25 minutes, and then react for 2 hours under ultrasonic to prepare a superhydrophobic coating spray .

[0044] The surface of C25 concrete was protected with the prepared superhydrophobic spray. Before spraying the protective agent, clean the slag and floating dust on the concrete surface with a brush,...

Embodiment 3

[0046] A superhydrophobic coating spray for glass surface protection and its preparation and use method. The material is composed of nano-titanium dioxide, sodium methyl silicate and tetrahydrofuran with a particle size of 30nm. The preparation process and method are as follows:

[0047] Add 0.4 parts by weight of nano-titanium dioxide into 89.6 parts of tetrahydrofuran, ultrasonicate for 5 minutes, and then disperse with a high-speed homogenizer for 6 minutes. Then, use sodium hydroxide solution to adjust the pH to 7.5, and under magnetic stirring, add 10 parts of sodium methyl silicate dropwise at a constant speed, and the dropping time is controlled at 16 minutes, and then react for 3 hours under ultrasonic to prepare a superhydrophobic coating spray .

[0048] The glass surface was treated with the prepared superhydrophobic spray. Before spraying the protective agent, first clean the glass surface with tap water and dry it, and then spray superhydrophobic spray, the nozzl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Surface contact angle | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com