Preparation method and application of nanometer zero-valent ion composite material

A technology of nano-zero-valent iron and composite materials, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of loss of nano-characteristics, reduced reactivity, strong reactivity, etc., and achieve improved removal rate , solve the effect of agglomeration and activity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

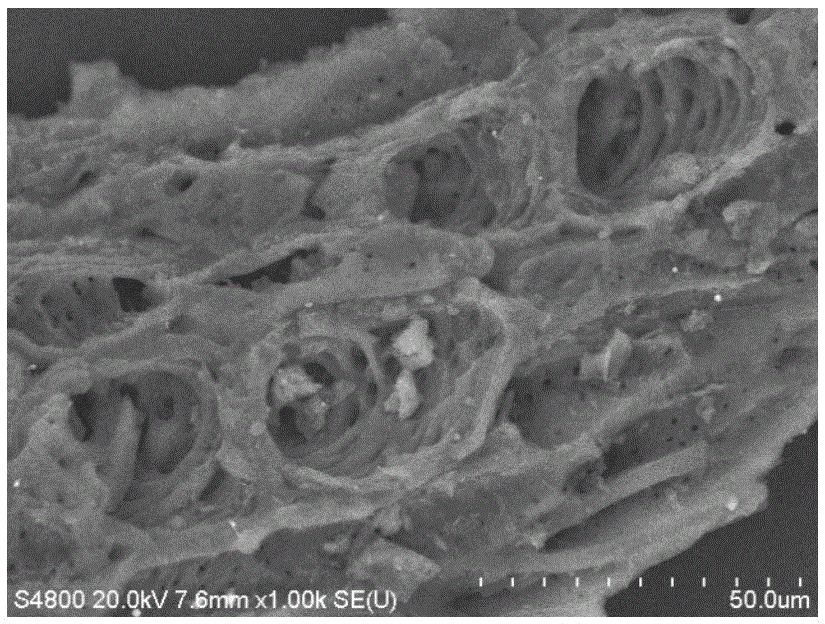

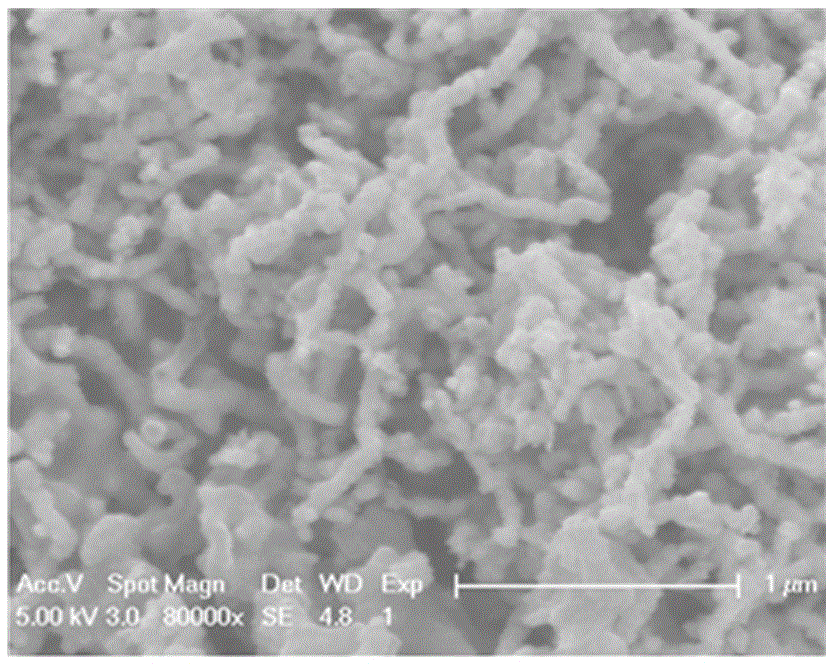

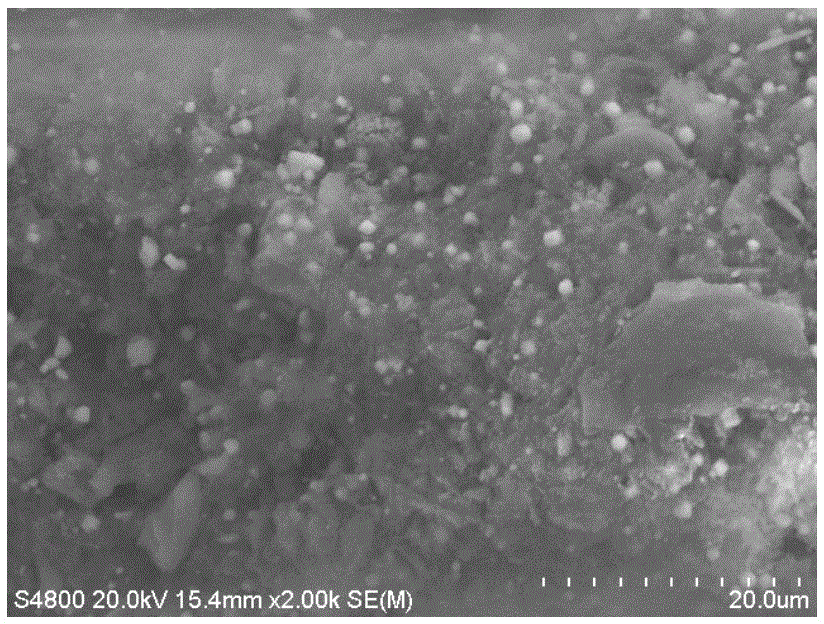

[0027] Because the nano zero-valent iron particles are easy to agglomerate, the particle size becomes larger, loses many nano-characteristics based on small size, and reduces the reactivity. Many studies at home and abroad have loaded nano-zero-valent iron on montmorillonite, bentonite, activated carbon, resin and other carriers to enhance its dispersion, but there are few reports on using biochar as a carrier, especially in the application of removing lead ions in water. has not been reported yet. Biochar (biochar) refers to the stable, highly aromatic carbon-rich solid material produced by high-temperature slow pyrolysis (usually <700 °C) of raw materials such as biomass and fossil fuels under oxygen-limited conditions. From the microstructure point of view, most biochars are composed of tightly packed and highly twisted aromatic ring sheets, with remarkable porosity. Compared with other carriers, biochar has a tubular porous structure and a larger specific surface area, wh...

Embodiment 1

[0041] Clean the corn stalks, dry them in an oven at 80°C for 48 hours, crush them, and set aside;

[0042] The crushed corn stalks were put into a crucible, placed in an anaerobic tube furnace, and fed with nitrogen for 30 minutes. Carbonize at 100°C for 1 hour, and carbonize at 400°C for 3 hours (heating rate is 10°C / min). After pyrolysis and cooling, take out the carbonized material, grind and pulverize it with a mortar, pass through an 80-mesh sieve, and make powdery biochar;

[0043] Under the condition of 85°C, modify the powdery biochar with 10% nitric acid solution for 8 hours, wash it with ultrapure water until neutral, dry it at 80°C, put it into a brown bottle and put it in a desiccator for later use;

[0044] 1gFeSO 4 •7H 2 O dissolved in 100mL ethanol solution (V 水 :V 乙醇 =1:4), ultrasonically oscillated for 5 minutes to make ferrous sulfate ethanol solution. The prepared ferrous sulfate solution and 1g of biochar powder were placed in a 500mL three-necked fl...

Embodiment 2

[0048] Clean the corn stalks, dry them in an oven at 80°C for 48 hours, crush them, and set aside;

[0049] The crushed corn stalks were put into a crucible, placed in an anaerobic tube furnace, and fed with nitrogen for 30 minutes. Carbonize at 100°C for 1 hour, and carbonize at 400°C for 3 hours (heating rate is 10°C / min). After pyrolysis and cooling, take out the carbonized material, grind and pulverize it with a mortar, pass through an 80-mesh sieve, and make powdery biochar;

[0050] Under the condition of 85°C, modify the powdery biochar with 20% nitric acid solution for 8 hours, wash it with ultrapure water until neutral, dry it at 80°C, put it into a brown bottle and put it in a desiccator for later use;

[0051] 1gFeSO 4 •7H 2 O dissolved in 100mL ethanol solution (V 水 :V 乙醇 =1:4), ultrasonically oscillated for 5 minutes to make ferrous sulfate ethanol solution. The prepared ferrous sulfate solution and 1g of biochar powder were placed in a 500mL three-necked fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com