Sulfuric acid recovery method and system

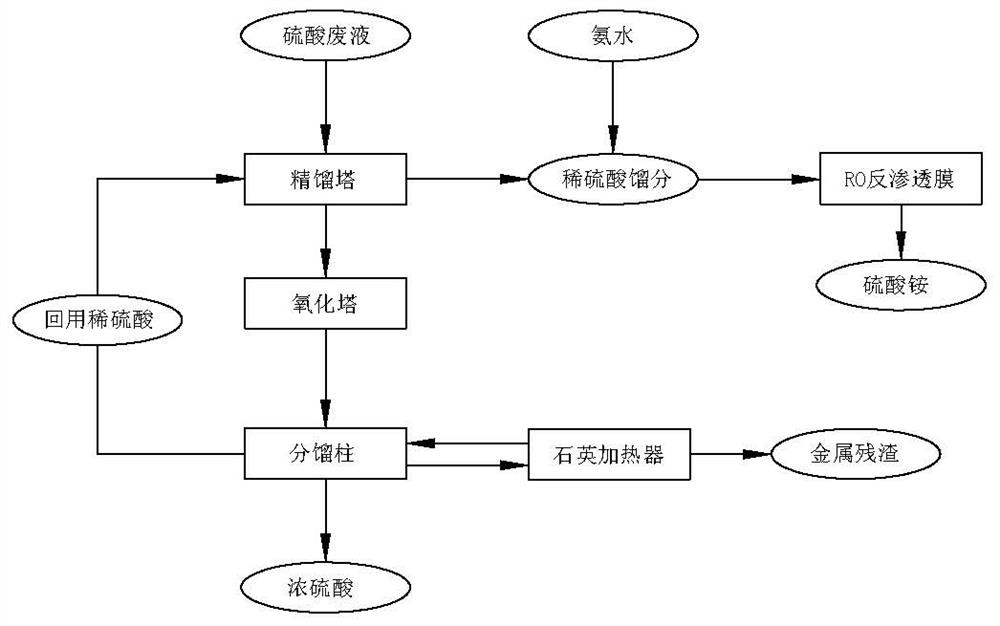

A recovery system and recovery method technology, applied in sulfur trioxide/sulfuric acid, chemical instruments and methods, sulfur compounds, etc., can solve the problems of high energy consumption, high production cost, inconvenient disposal of sulfuric acid waste liquid, etc., and reduce energy consumption. , Low production cost, good recycling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

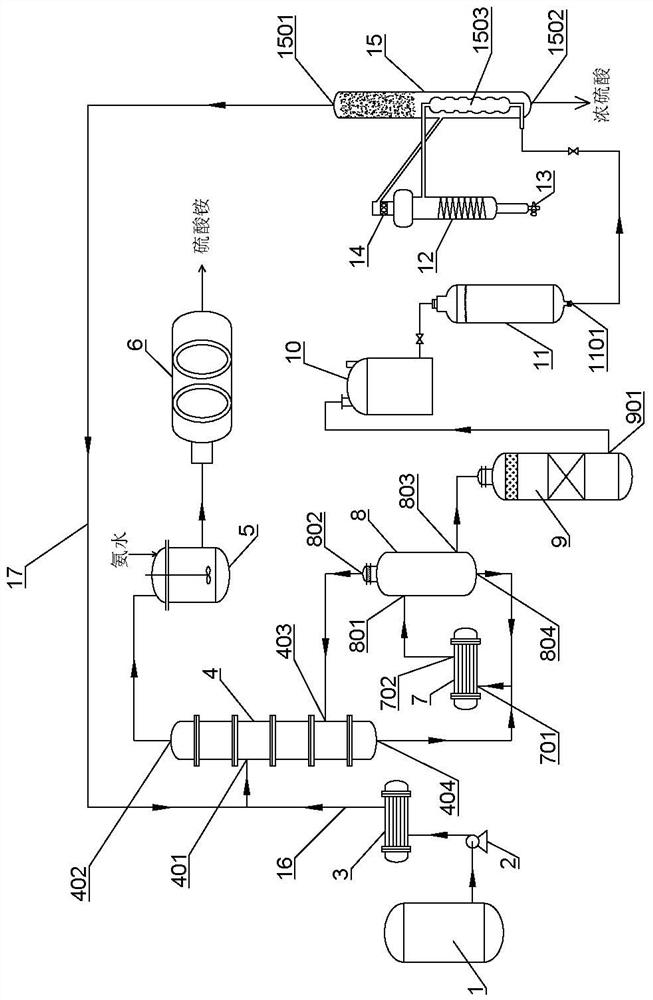

[0036] A rectification tower equipped with a negative pressure device and connected to the inlet of the reboiler circulation loop is used to perform rectification and pre-concentration on the sulfuric acid waste liquid with a mass fraction of sulfuric acid of 50% and a mass fraction of impurities of 2% at 180°C. The impurities are hydrogen peroxide, hydrogen peroxide, and Metal salt (Fe 2 (SO 4 ) 3 、CuSO 4 ) and organic matter (ketones and toluene), the pressure is -10 KPa, hydrogen peroxide reacts with ketone organic matter to achieve partial removal, and obtain a sulfuric acid pre-concentrate with a sulfuric acid mass fraction of 80% and a dilute sulfuric acid fraction of 0.6%; the sulfuric acid mass fraction The 0.6% dilute sulfuric acid distillate is condensed, passed through ammonia water, and then filtered by RO reverse osmosis membrane, and the obtained ammonium sulfate is used for the preparation of agricultural fertilizers.

[0037] The sulfuric acid pre-concentrat...

Embodiment 2

[0040] A rectification tower equipped with a negative pressure device and connected to the inlet of the reboiler circulation loop is used to perform rectification and pre-concentration on the sulfuric acid waste liquid with a mass fraction of sulfuric acid of 60% and a mass fraction of impurities of 2.5% at 190°C. The impurities are hydrogen peroxide, hydrogen peroxide, and Metal salt (Fe 2 (SO 4 ) 3 、CuSO 4 and NiSO 4 ) and ketone organic matter, the pressure is -15 KPa, hydrogen peroxide reacts with ketone organic matter to achieve double removal, and obtain a sulfuric acid pre-concentrate with a sulfuric acid mass fraction of 85% and a dilute sulfuric acid fraction of 0.8%; a sulfuric acid mass fraction of 0.8% After the dilute sulfuric acid fraction is condensed, ammonia water is passed into it, and then RO reverse osmosis membrane is used for filtration, and the obtained ammonium sulfate is used for the preparation of agricultural fertilizer.

[0041] A fractionation ...

Embodiment 3

[0043] A rectification tower equipped with a negative pressure device and connected to the inlet of the reboiler circulation loop is used to perform rectification and pre-concentration on the sulfuric acid waste liquid with a mass fraction of sulfuric acid of 55% and a mass fraction of impurities of 3% at 185°C. The impurities are hydrogen peroxide, hydrogen peroxide, and Metal salt (Fe 2 (SO 4 ) 3 、CuSO 4 、NiSO 4 ) and organic matter (ketones, alcohols), the pressure is -13 KPa, hydrogen peroxide reacts with ketone organic matter to achieve partial removal, and obtain a sulfuric acid pre-concentrate with a sulfuric acid mass fraction of 82% and a dilute sulfuric acid fraction of 0.7%; the mass fraction of sulfuric acid The dilute sulfuric acid fraction with a fraction of 0.7% is condensed and passed into ammonia water, and then filtered through RO reverse osmosis membrane, and the obtained ammonium sulfate is used for the preparation of agricultural fertilizers.

[0044] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com