EVA-modified polyurethane composite shoe material and preparation method thereof

A polyurethane and modified technology, which is applied in the field of shoe materials, can solve the problems of discarding, and achieve the effects of reducing internal stress, excellent tensile strength, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of EVA modified polyurethane composite shoe material, comprises the raw material of following weight portion:

[0035]

[0036] The isocyanate is preferably diphenylmethane diisocyanate; the anti-yellowing agent is the PU anti-yellowing agent UV-41 produced by Anhui Sancai Industry and Trade Co., Ltd.; the color paste is produced by Dongguan Sanhua Chemical Coating Co., Ltd. polyurethane color paste.

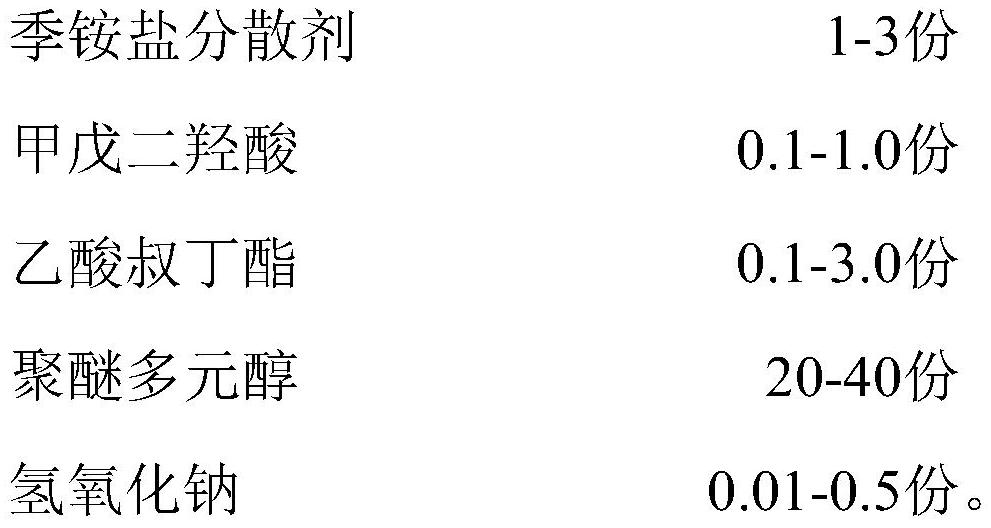

[0037] Each part of the modified polyether polyol includes the raw materials of the following parts by weight:

[0038]

[0039] The polyether polyol is preferably tetrahydrofuran-propylene oxide copolymerized glycol; the quaternary ammonium salt dispersant is preferably quaternary ammonium salt dispersant XW330.

[0040] Described modified polyether polyol is obtained by following method:

[0041] S1. According to parts by weight, add meglutaric acid, quaternary ammonium salt dispersant and polyether polyol into the reaction device and mix evenly, and heat...

Embodiment 2

[0055] A kind of EVA modified polyurethane composite shoe material, comprises the raw material of following weight portion:

[0056]

[0057] The isocyanate is preferably diphenylmethane diisocyanate; the anti-yellowing agent is the PU anti-yellowing agent UV-41 produced by Anhui Sancai Industry and Trade Co., Ltd.; the color paste is produced by Dongguan Sanhua Chemical Coating Co., Ltd. polyurethane color paste.

[0058] Each part of the modified polyether polyol includes the raw materials of the following parts by weight:

[0059]

[0060]

[0061] The polyether polyol is preferably tetrahydrofuran-propylene oxide copolymerized glycol; the quaternary ammonium salt dispersant is preferably quaternary ammonium salt dispersant XW330.

[0062] Described modified polyether polyol is obtained by following method:

[0063] S1. According to parts by weight, add meglutaric acid, quaternary ammonium salt dispersant and polyether polyol into the reaction device and mix even...

Embodiment 3

[0077] A kind of EVA modified polyurethane composite shoe material, comprises the raw material of following weight portion:

[0078]

[0079] The isocyanate is preferably diphenylmethane diisocyanate; the anti-yellowing agent is the PU anti-yellowing agent UV-41 produced by Anhui Sancai Industry and Trade Co., Ltd.; the color paste is produced by Dongguan Sanhua Chemical Coating Co., Ltd. polyurethane color paste.

[0080] Each part of the modified polyether polyol includes the raw materials of the following parts by weight:

[0081]

[0082] The polyether polyol is preferably tetrahydrofuran-propylene oxide copolymerized glycol; the quaternary ammonium salt dispersant is preferably quaternary ammonium salt dispersant XW330.

[0083] Described modified polyether polyol is obtained by following method:

[0084] S1. According to parts by weight, add meglutaric acid, quaternary ammonium salt dispersant and polyether polyol into the reaction device and mix evenly, and heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com