20W thick-film and high-frequency load plate and production method thereof

A production method and load chip technology, applied in the direction of electrical components, circuits, waveguide devices, etc., can solve the problems of high equipment cost and difficult production control, and achieve the effect of small market size, guaranteed smoothness, and good characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0035]Ethyl cellulose is 30 parts by weight, rosin is 15 parts by weight and diethylene glycol butyl ether is 55 parts by weight, dissolves and mixes uniformly, makes organic vehicle, and viscosity is 30960cps; Silver powder 62g, glass powder 5g, the organic vehicle of gained 25g, 2g of terpineol and 1g of solid thixotropic agent, mixed evenly, the measured slurry viscosity was 50010cps; Grinding: Grinding by three-roll machine, the measured slurry fineness was 10μm.

preparation example 2

[0037] Ethyl cellulose is 30 parts by weight, rosin is 10 parts by weight and diethylene glycol butyl ether is 60 parts by weight, dissolved and mixed uniformly to obtain an organic vehicle, the viscosity is 31160cps; silver powder 55g, glass powder 4g, the organic vehicle obtained 33g, 0.5g of terpineol and 0.5g of solid thixotropic agent were mixed evenly, and the measured slurry viscosity was 54930cps; Grinding: Grinding with a three-roll machine, and the measured slurry fineness was 8 μm.

Embodiment 1

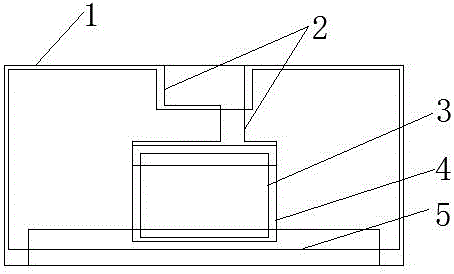

[0039] Such as figure 1 As shown, the thick-film high-frequency 20-watt load sheet includes an aluminum nitride substrate (1) of 5*2.5*0.635mm, and a back guide layer is printed on the back of the aluminum nitride substrate, and the aluminum nitride substrate Resistors (3) and wires (2) are printed on the front side, the wires are connected to the resistors to form a load circuit, the ground terminal of the load circuit is electrically connected to the back conductive layer through silver paste, and the resistors are printed with glass protection film (4), the upper surface of the conductive wire and glass protective film is also printed with a layer of black protective film (5), the paste of the front resistance of the printed substrate adopts the thixotropic paste of Preparation Example 1, and passes through a 400-mesh high-precision steel mesh Plate printing paste, back conductive layer and wires are printed with conductive silver paste, and the resistor is printed with res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com