Archaistic black brick production process and equipment

An antique blue brick and production process technology, applied in the production of ceramic materials, lighting and heating equipment, clay preparation devices, etc., can solve the problems affecting the quality of finished products, uneven texture, insufficient mixing of raw materials, etc., to avoid excessively low pressure. , to avoid excessive pressure and save the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The invention discloses a production process of antique green bricks, which comprises the steps of raw material treatment, billet making, drying, firing and drying.

[0048] Wherein, the raw material processing process includes raw material preparation and raw material stirring. During the raw material stirring process, steam is passed on the raw material while stirring. After the raw material stirring process is completed, the water content of the raw material is 16%-20%.

[0049] The present embodiment prepares 5 kilns respectively with water mixing process and steam mixing process and compares (other conditions are consistent, including mixing time), observes the surface and the section surface of the blue brick produced, and the blue brick prepared by steam mixing process, Its organizational structure is more consistent, the particles are consistent, the color is uniform, and the size of the pores is uniform; while the blue bricks mixed with water have some inclusion...

Embodiment 2

[0060] In order to implement the aforementioned process, the present invention also discloses an antique blue brick production equipment, which includes a double-screw mixing conveyor, a steam supply device, a screw conveyor, a heating room, a billet making machine and a drawer kiln.

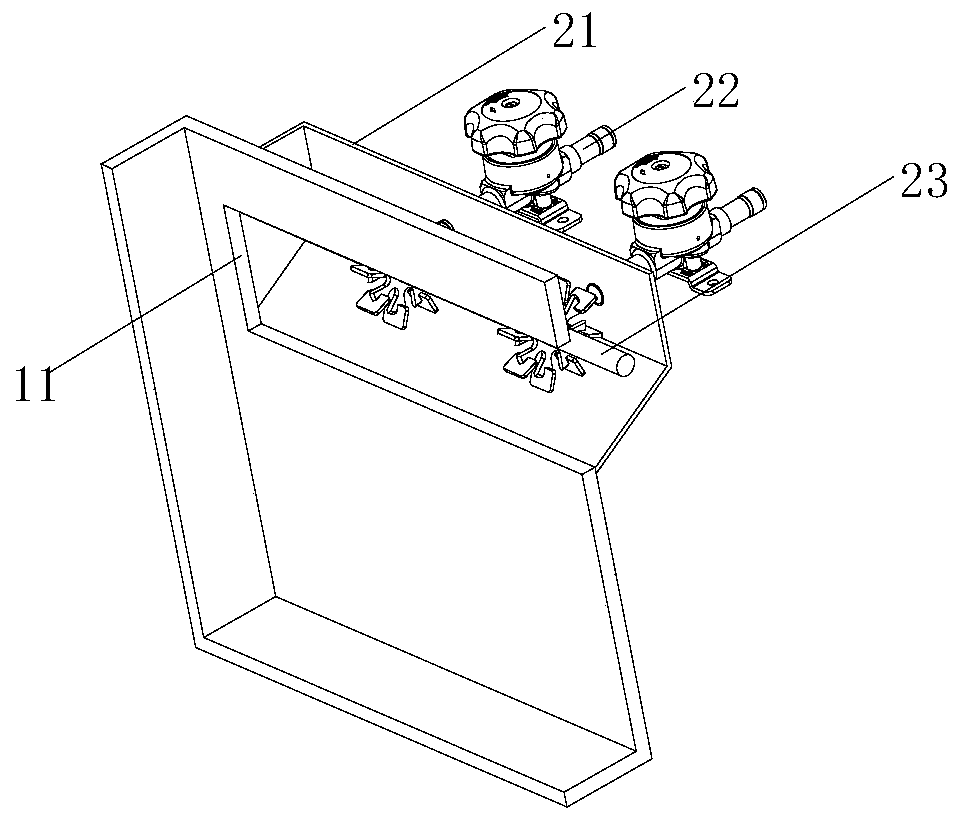

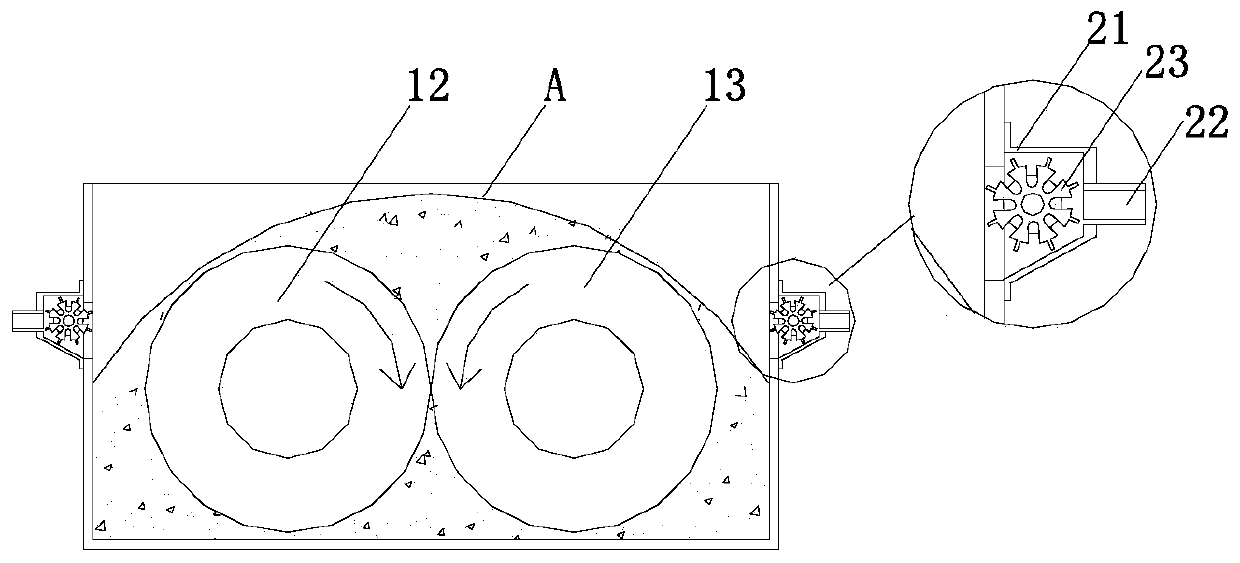

[0061] Please refer to figure 1 , figure 2 and image 3 As shown, the two side walls of the double-screw mixing conveyor 1 are provided with a steam inlet 11, and the setting height H of the steam inlet 11 meets H1≤H≤(H1+H2), and the H1 is the screw shaft of the double-screw mixing conveyor 1 The height of the shaft center, the H2 is the height from the shaft center of the screw shaft to the center of the uplift of the material when the double-screw mixing conveyor is working. The steam supply device 2 supplies steam to the double-screw mixing conveyor 1 through the steam inlet 11 .

[0062] In this way, when the double-screw mixing conveyor 1 is working, the screw shaft on the left side run...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com