Preparation method of Hf<x>Ta<1-x>C alloy precursor and Hf<x>Ta<1-x>C alloy prepared therefrom

A technology of precursors and alloys, which is applied in the field of preparation of HfxTa1-xC alloy precursors and alloys, can solve the problems that the precursors do not have processability, cannot be prepared for composite materials, coatings or fibers, etc., and achieve excellent solubility, The effect of improving the purity and requiring less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

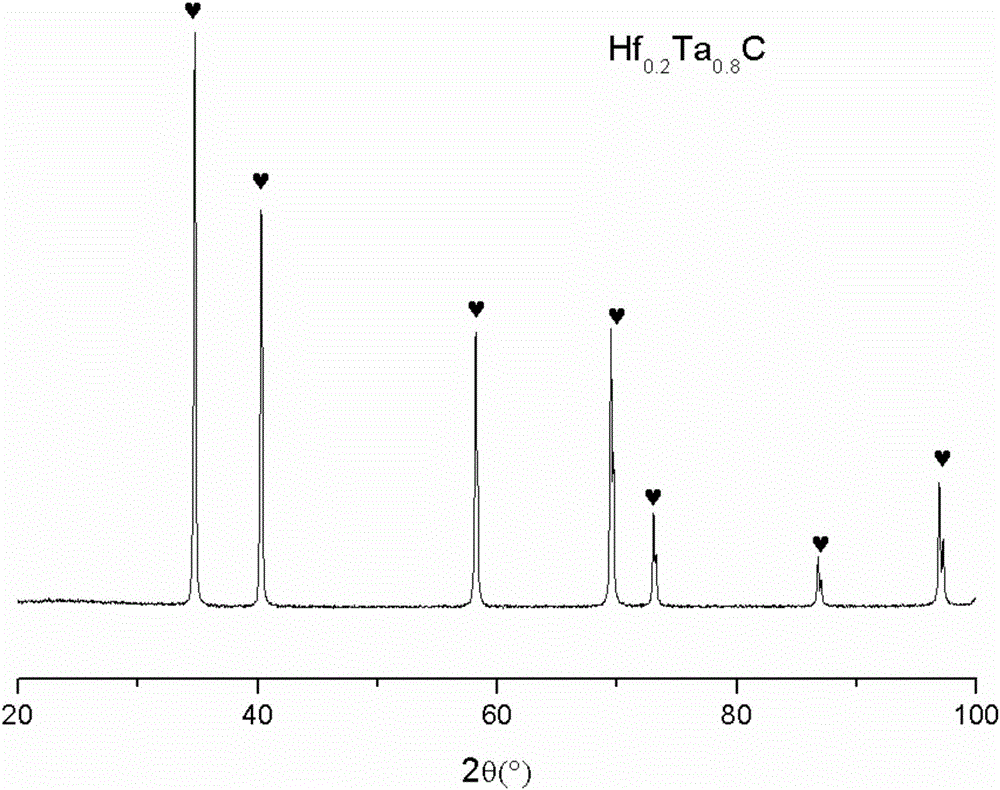

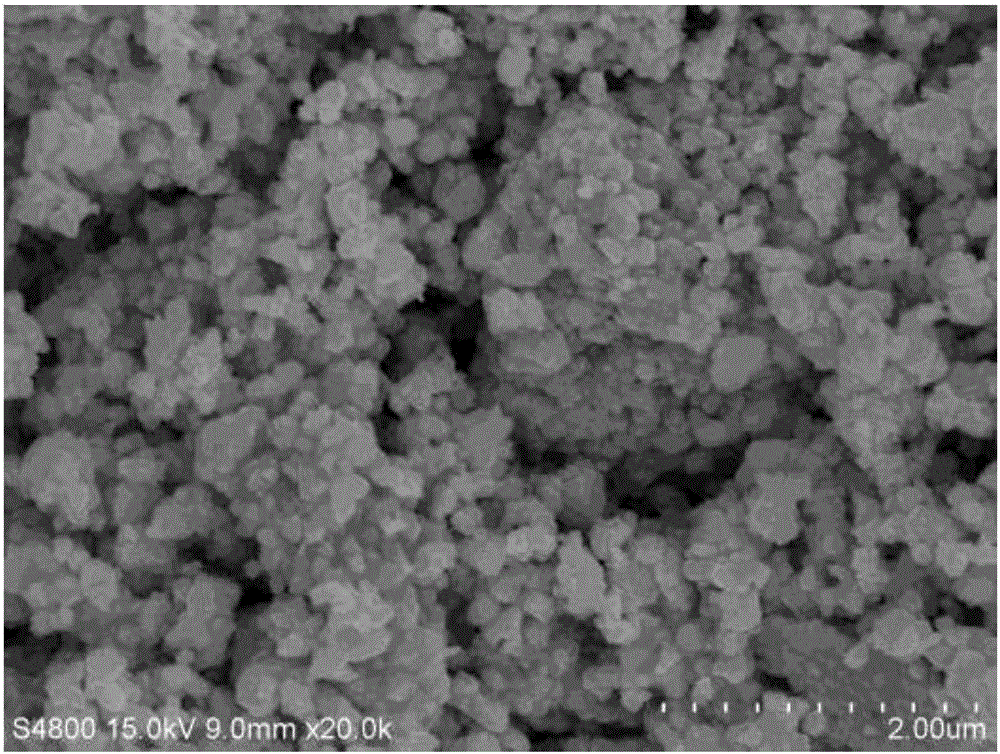

Embodiment 1

[0042] Hf in this example 0.2 Ta 0.8 The C precursor is synthesized by the following steps:

[0043] 1. Preparation of hafnium alkoxide: disperse 1 mol of hafnium tetrachloride in 30 mol of n-hexane, add dropwise a mixture of 4.5 mol of n-propanol and 4 mol of triethylamine at -5°C, heat and reflux for 1 hour after the addition, and filter to obtain hafnium alcohol saline solution;

[0044] 2. Preparation of tantalum alkoxide: disperse 4 mol of tantalum pentachloride in 240 mol of ethylene glycol dimethyl ether, drop in a mixture of 24 mol of isopropanol and 24 mol of triethylamine at 10°C, heat and reflux for 5 hours after the addition, and filter to obtain Tantalum alkoxide solution;

[0045] 3. Preparation of hafnium-tantalum polymer precursor by co-hydrolysis: Mix the hafnium alkoxide and tantalum alkoxide solutions obtained in steps 1 and 2, add 2.5mol acetylacetone dropwise at room temperature, reflux for 0.5h after dropping, cool down to room temperature, drop into ...

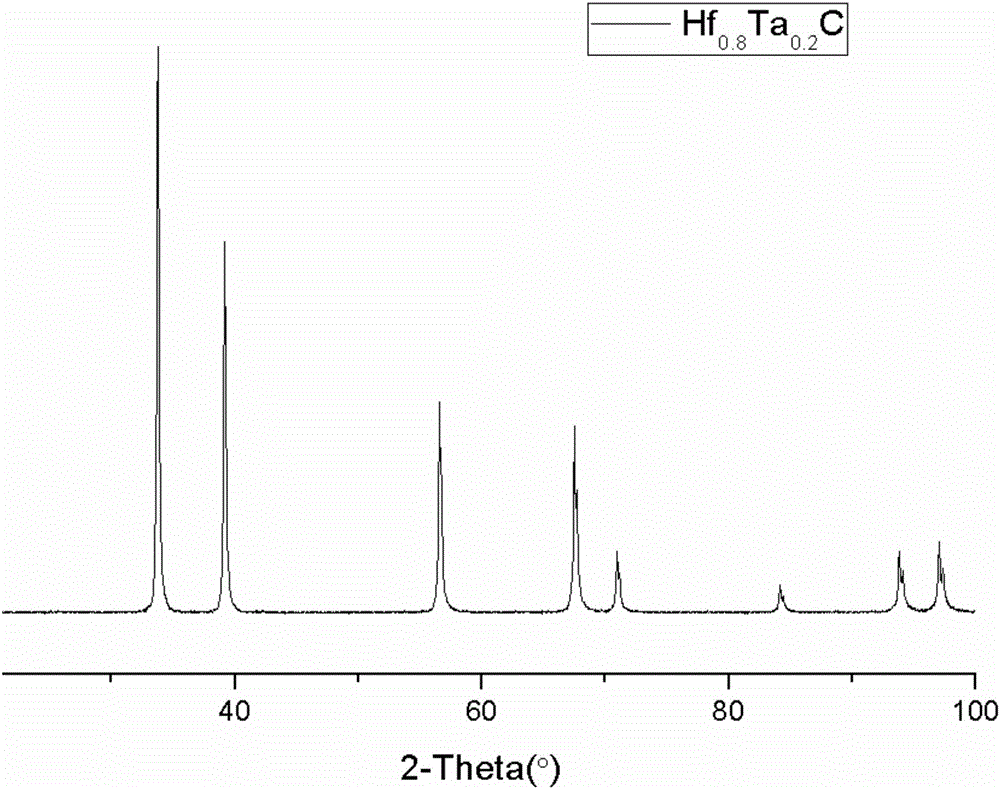

Embodiment 2

[0049] Hf in this example 0.8 Ta 0.2 The C precursor is synthesized by the following steps:

[0050] 1. Preparation of hafnium alkoxide: disperse 4 mol of hafnium tetrachloride in 200 mol of n-heptane, add dropwise a mixture of 28 mol of isopropanol and 20 mol of triethylamine at 10°C, heat under reflux for 5 hours after the addition, and filter to obtain hafnium alkoxide solution;

[0051] 2. Preparation of tantalum alkoxide: Disperse 1 mol of tantalum pentachloride in 40 mol of xylene, drop in a mixture of 9 mol of n-butanol and 5 mol of triethylamine at -5°C, heat and reflux for 1 hour after the addition, and filter to obtain tantalum alkoxide solution;

[0052] 3. Preparation of hafnium-tantalum polymer precursor by co-hydrolysis: Mix the hafnium alkoxide and tantalum alkoxide solutions obtained in steps 1 and 2, add 5 mol ethyl acetoacetate dropwise at 80°C, reflux for 5 hours after dropping, drop to 50°C, drop Add the mixed solution of 7.5mol water and 40mol n-butano...

Embodiment 3

[0056] Hf in this example 0.5 Ta 0.5 The C precursor is synthesized by the following steps:

[0057] 1. Preparation of hafnium alkoxide: disperse 1 mol of hafnium tetrachloride in 40 mol of toluene, add dropwise a mixture of 5 mol of isobutanol and 4.5 mol of triethylamine at 5°C, heat and reflux for 2 hours after the addition, and filter to obtain hafnium alkoxide solution ;

[0058] 2. Preparation of tantalum alkoxide: disperse 1mol tantalum pentachloride in 50mol ethylene glycol dimethyl ether, add dropwise a mixture of 7mol ethylene glycol monomethyl ether and 5.5mol triethylamine at 3°C, and heat to reflux after the addition 3h, filtered to obtain tantalum alkoxide solution;

[0059]3. Preparation of hafnium-tantalum polymer precursor by co-hydrolysis: Mix the hafnium alkoxide and tantalum alkoxide solutions obtained in steps 1 and 2, add 3 mol of acetylacetone dropwise at room temperature, reflux for 2 hours after dropping, at 80°C, add 2.0 mol of water dropwise Mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com