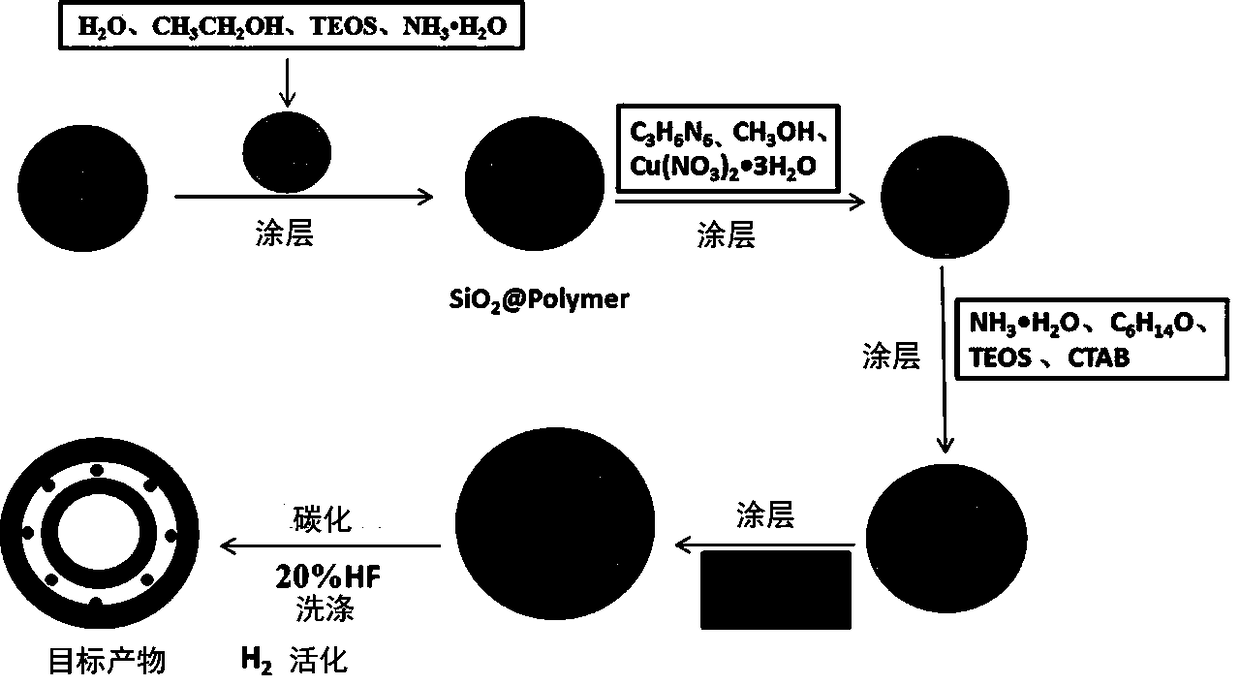

A kind of preparation method of double-layer hollow nitrogen-doped carbon ball-coated copper nano-catalyst

A nano-catalyst, double-layer hollow technology, used in the preparation of organic compounds, chemical instruments and methods, catalysts for physical/chemical processes, etc. The effect of the spatial confinement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The chemical materials used in the present invention are: absolute ethanol, deionized water, ammonia water, tetraethyl orthosilicate (TEOS), 3-aminophenol, formaldehyde, melamine, copper nitrate, methanol, hexadecyl trimethyl bromide Ammonium chloride (CTAB), hydrofluoric acid (40%), high-purity nitrogen, high-purity hydrogen, the preparation amount is as follows: in grams, milliliters, centimeters 3 as a unit of measurement

[0019] Absolute ethanol:CH 3 CH 2 OH liquid 100ml±0.1ml

[0020] Deionized water: H 2 O Liquid 3000ml±50ml

[0021] Ammonia:NH 3 •H 2 O Liquid 6ml±0.1ml

[0022] Methanol:CH 3 OH liquid 40ml±0.1ml

[0023] Ethyl orthosilicate: C 4 h 12 o 4 Si liquid 6ml±0.1ml

[0024] Formaldehyde: HCHO liquid 0.61ml±0.01ml

[0025] n-Hexanol: C 6 h 14 O Liquid 30ml±0.1ml

[0026] Hydrofluoric acid: HF liquid 300ml±10ml

[0027] Hexadecyltrimethylammonium bromide: C 19 h 42 BrN solid 5g±0.001g

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com