Cationic monomer for zwitterionic copolymer, preparation method thereof, zwitterionic copolymer, preparation method and application thereof

A cationic monomer, zwitterion technology, applied in the field of copolymers, can solve the problems of poor temperature resistance and low selectivity of zwitterionic copolymers, and achieve the effect of good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

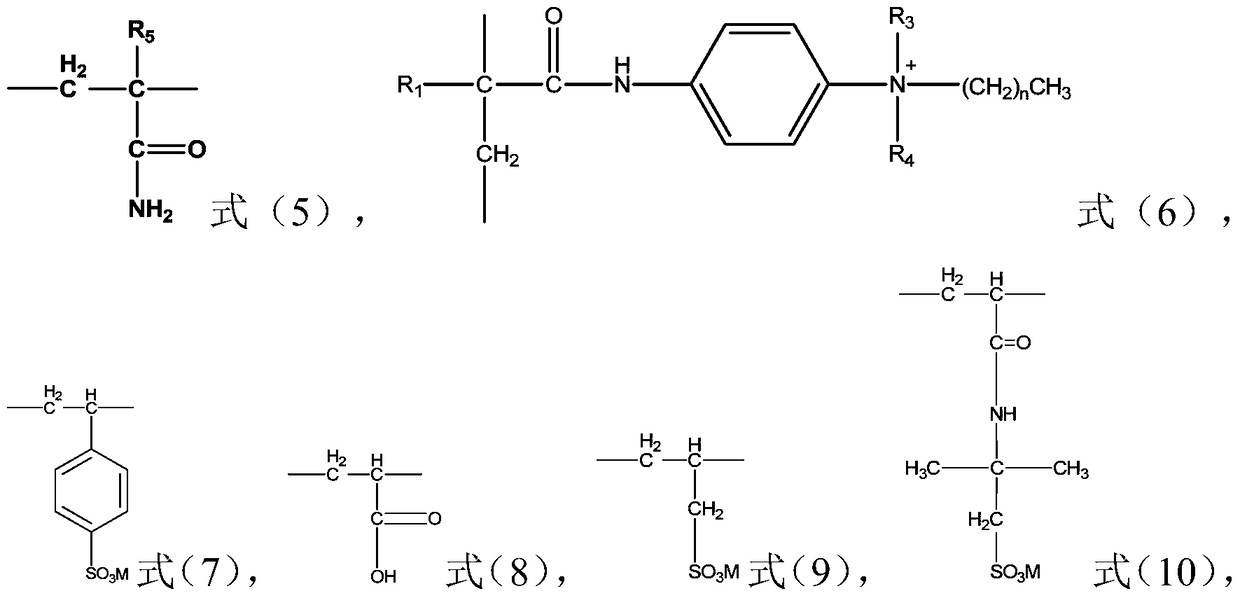

Examples

preparation example Construction

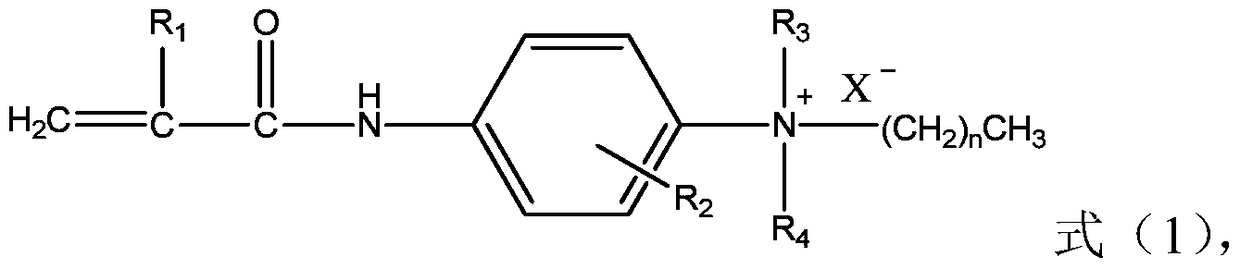

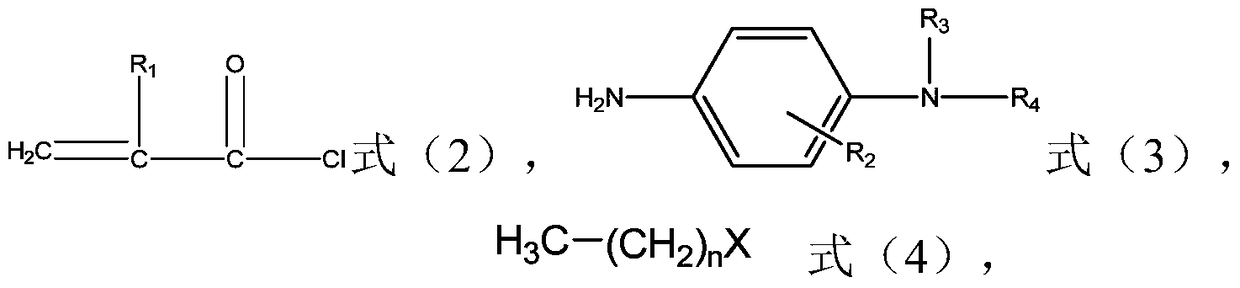

[0039] In a second aspect, the present invention provides a method for preparing the aforementioned cationic monomer for the zwitterionic copolymer, the method comprising:

[0040] (1) Under alkaline conditions, the monomer shown in formula (2) is contacted with the compound shown in formula (3) in an organic solvent;

[0041] (2) The product obtained through step (1) is mixed with the compound shown in formula (4);

[0042]

[0043] Among them, R 1 , R 2 , R 3 , R 4 , X and n are as defined above in the present invention.

[0044] According to the present invention, the relevant definition of the cationic monomer for the zwitterionic copolymer in the preparation method of the cationic monomer for the zwitterionic copolymer is as described above in the present invention. In order to avoid repetition, the present invention will not repeat them here.

[0045] In step (1), the conditions of the contact reaction may include: a temperature of 5-30° C., and a time of 20-240 ...

preparation example 1

[0087] This preparation example is used to prepare methacryloyl chloride (a kind of in the monomer shown in formula (2)):

[0088] Install a stirrer, a fractionating column, a dropping funnel, and a thermometer on the four-neck flask, and install a receiving bottle with a vacuum tailpiece behind the condenser. Add 3.0 mol of benzoyl chloride, 0.3 mol of methacrylic acid and 0.7 g of cuprous chloride into the flask. Add 2.7mol of methacrylic acid to the dropping funnel. Start the vacuum pump to control the vacuum to 0.2MPa. Heat and stir until the temperature reaches 75°C, and methacryloyl chloride distills out from the receiving bottle. At the same time, methacrylic acid was added dropwise with a dropping funnel. Heated and stirred for 60 minutes. Obtain methacryloyl chloride product for use.

preparation example 2

[0090] This preparation example is used to prepare the cationic monomer (dimethyl dodecyl bromide (2-methacrylamido-p-phenyl) ammonium bromide) for the zwitterionic copolymer:

[0091] (1) In a three-neck round bottom flask equipped with a stirrer and a nitrogen pipe, add 250 mL of dichloromethane, 0.3 mol of 4-amino-N,N-dimethylaniline and 40 mL of 9 mol / L sodium hydroxide solution. Nitrogen was blown in, and the solution was stirred and dissolved at 5°C. 0.3mol of methacryloyl chloride dissolved in 50mL of dichloromethane was added dropwise with the dropping funnel. The reaction was stirred for 90 min. The organic layer was separated, and the solvent was distilled off to obtain 50.9 g of the product. Add 0.08 g of phenothiazine to the obtained product, and distill under reduced pressure. Collect fractions at 90-100°C and vacuum degree of 50Pa, and the product obtained is methacrylamide-p-phenyldimethylamine;

[0092] (2) Stir and mix 0.1 mol of methacrylamide-p-phenyldim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com