Lithium secondary battery composite graphite and preparation method thereof

A lithium secondary battery and composite graphite technology, which is applied to secondary batteries, graphite, battery electrodes, etc., can solve the problems of poor fast charge and discharge performance, long lithium ion diffusion path, troublesome processing procedures, etc., and achieve excellent overall performance, The preparation method is simple and feasible, and the effect of stable product properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

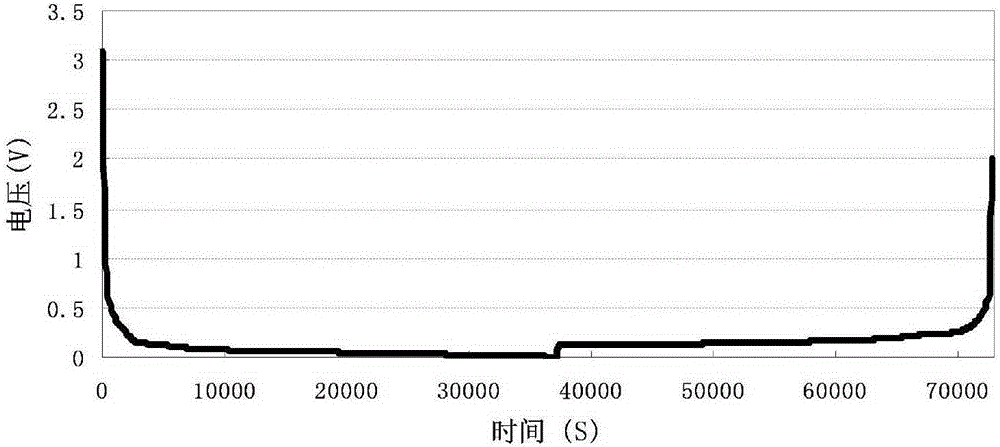

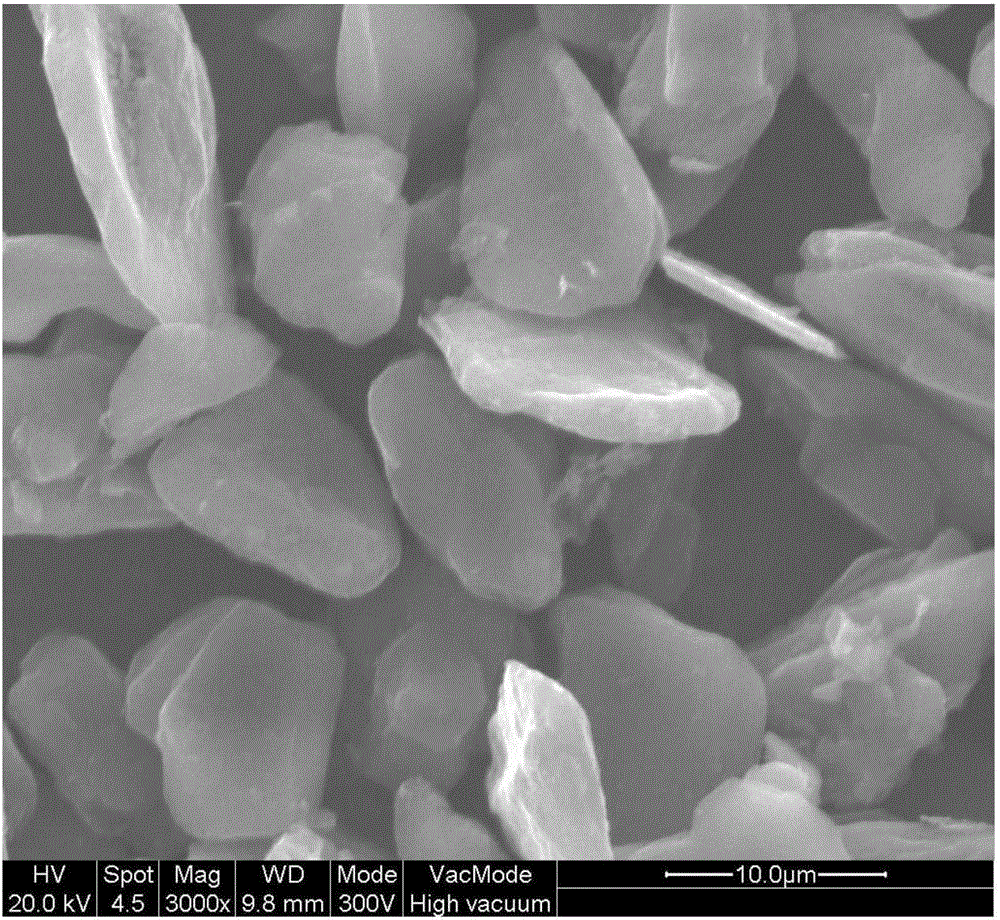

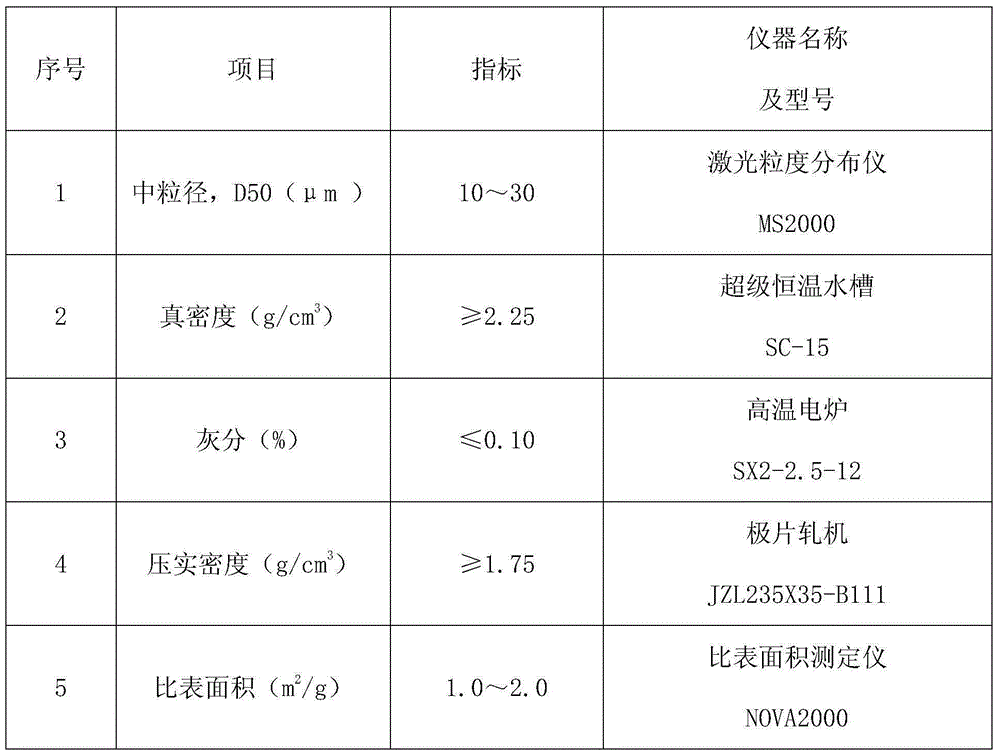

Embodiment 1

[0031] The petroleum asphalt is crushed to below 5 μm, and 200 kg of petroleum asphalt coke powder (D50 is 9.1 μm) and 60 kg of asphalt powder, graphitization catalyst (SiO 2 ) 16kg to mix in the mixing pot. Under the protection of nitrogen, heat treatment at a low temperature of 500°C for 16 hours, then cool the reaction product to room temperature, composite granulate, and then carry out a high-temperature catalytic graphitization treatment at 2800°C for 36 hours, mix and sieve, and obtain The lithium secondary battery composite graphite with a particle size D50 of 17.8 μm has a half-cell capacity of 367.5mAh / g and an initial efficiency of 95.8%.

Embodiment 2

[0033] The petroleum asphalt is crushed to below 5 μm, and under stirring, 200 kg of petroleum asphalt coke powder (D50 is 9.5 μm), 20 kg of asphalt powder, and 6 kg of graphitization catalyst (SiC) are alternately added to the mixing pot for mixing. Under the protection of nitrogen, heat treatment at a low temperature of 500°C for 16 hours, then cool the reaction product to room temperature, compound granulate, and carry out high-temperature treatment of catalytic graphitization at 3000°C for 48 hours, mixing and sieving to obtain The particle diameter D50 is 18.3 μm lithium secondary battery composite graphite, its half battery capacity is 368.1mAh / g, and the first efficiency is 96.2%.

Embodiment 3

[0035] Coal tar pitch is pulverized to less than 5 μm, and 200 kg of coal tar pitch coke powder (D50 is 5.1 μm) and 40 kg of pitch powder, graphitization catalyst (SiO 2 ) 10kg to mix in the mixing pot. Under the protection of nitrogen, heat treatment at a low temperature of 800°C for 10 hours, then cool the reaction product to room temperature, compound granulate, and carry out high-temperature treatment of catalytic graphitization at 3200°C for 48 hours, mixing and sieving to obtain The particle diameter D50 is 17.4 μm and the lithium secondary battery composite graphite has a half-cell capacity of 370.0mAh / g and an initial efficiency of 95.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com