Preparation method of stereocomplex polylactic acid porous membrane material

A composite polylactic acid membrane and composite polylactic acid technology, applied in the field of polymer materials, can solve the problems of unenvironmental protection, complex preparation process, uneven product pore size distribution, etc., and achieve controllable structure, environmentally friendly preparation process, and complete biodegradability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Weigh 10g of number average molecular weight to be 5×10 4 g / mol of PLLA and 0.8 g of stannous octoate were dissolved in 500 mL of anhydrous toluene. React at 80°C for 2h under nitrogen atmosphere. After the reaction is finished, the obtained product is centrifuged and vacuum-dried to obtain a high-activity prepolymer. The obtained product was mixed with 10 g D The type lactide is mixed and added to the polymerization tube, filled with nitrogen and evacuated with oxygen, vacuumized, and repeated three times. Control the vacuum in the polymerization tube to be below 150 Pa, and react at 140°C for 72 hours to obtain stereocomplex polylactic acid.

[0032] (2) Dissolve the stereocomplex polylactic acid prepared in step (1) in chloroform at a concentration of 5g / 150mL. After fully dissolving, pour the solution into a quartz vessel, pour and volatilize to form a film.

[0033] (3) Prepare 0.1mol / L Tris solution and 0.1mol / L HCl solution, then take 500mL of 0.1mol / L Tr...

Embodiment 2

[0038] (1) Weigh 8g of the number average molecular weight of 1 × 10 5 g / mol of PDLA and 0.6 g of stannous octoate were dissolved in 500 mL of anhydrous toluene. React at 80°C for 3h under nitrogen atmosphere. After the reaction is finished, the obtained product is centrifuged and vacuum-dried to obtain a high-activity prepolymer. The obtained product was mixed with 8 g L The type lactide is mixed and added to the polymerization tube, filled with nitrogen and evacuated with oxygen, vacuumized, and repeated three times. Control the vacuum in the polymerization tube to be below 75 Pa, and react at 140°C for 72 hours to obtain stereocomplex polylactic acid.

[0039] (2) Dissolve the stereocomplex polylactic acid prepared in step (1) in chloroform at a concentration of 3g / 150mL. After fully dissolving, pour the solution into a quartz vessel, pour and volatilize to form a film.

[0040](3) Prepare 0.1mol / L Tris solution and 0.1mol / L HCl solution with a concentration of 0.15mol / ...

Embodiment 3

[0043] (1) Weigh the number average molecular weight to be 5.0×10 4 3 g / mol of PLLA and 3 g of PDLA were added to 100 ml of chloroform, stirred for 2 h to dissolve completely. Then the two solutions are blended and stirred, and after blending and stirring evenly, the solution is poured into a film to prepare a stereocomposite polylactic acid film material.

[0044] (2) Prepare a Tris solution with a concentration of 0.1mol / L and a 0.1mol / L HCl solution, take 500mL of a 0.1mol / L Tris solution, add a 0.1mol / L HCl solution, and set the volume to 1L to form a pH value of 9.0 buffer solution. Then, 2.0 mg of proteinase K and 2.0 mg of sodium azide were dissolved in 10 mL of buffer solution to prepare a proteinase K solution.

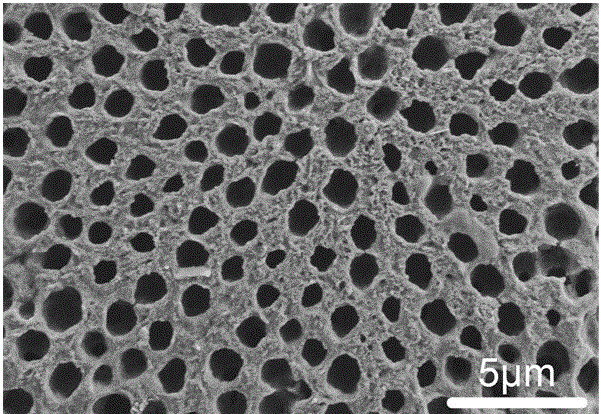

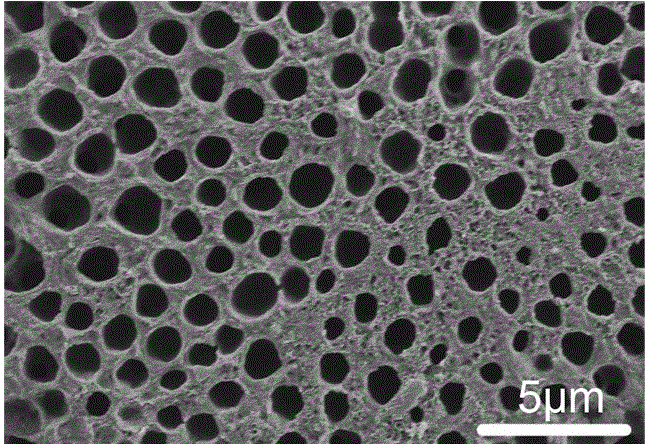

[0045] (3) Put the film prepared in step (1) into the proteinase K solution, degrade it in an oven at 37°C, take a sample after 72 hours, and dry it to obtain a stereocomposite polylactic acid porous film material. The obtained samples are as Figure 4 sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com