Preparation method of SrTiO3 and LaAlO3 dual-nanometer particle doping YBCO composite thin film

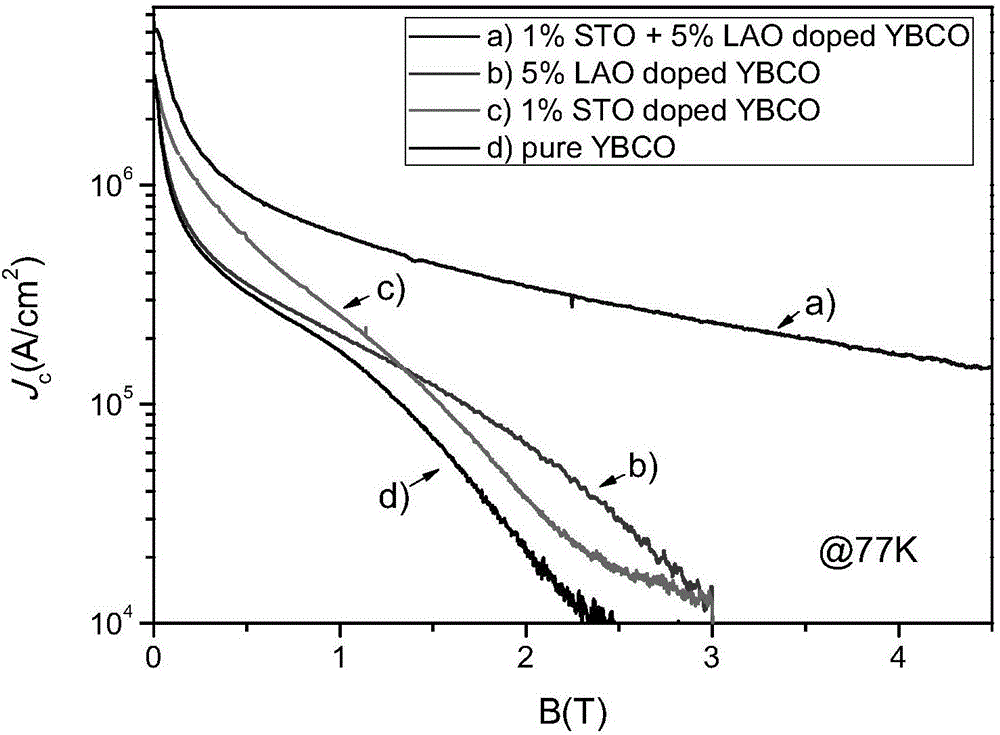

A nanoparticle and composite film technology, applied in cable/conductor manufacturing, usage of superconducting elements, superconducting/high-conducting conductors, etc. The effect of enhancing the bonding ability, improving the electrical conductivity, and improving the current carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025](1) Preparation of SrTiO 3 and LaAlO 3 Double nanoparticles doped YBCO composite precursor:

[0026] 1) Preparation of YBCO precursor solution: Dissolve 0.845g of yttrium acetate tetrahydrate and 1.275g of barium acetate tetrahydrate in deionized water, add 3.5ml of trifluoroacetic acid, stir in a water bath at 60°C for 3 hours, and place the resulting solution in a rotary evaporator Upward distillation, the distillation temperature is 60°C, the white powder obtained is added to anhydrous methanol to redissolve, and the precursor solution A of Y and Ba salt is obtained; 1.497g copper acetate tetrahydrate and 2.582g α-methacrylic acid are added to anhydrous methanol In , fully reflux reaction at 90°C for 3h, then carry out three distillations on a rotary evaporator, the distillation temperature is 40°C, evaporate to dryness and dissolve with anhydrous methanol to obtain Cu salt precursor solution B; mix precursor solutions A and B , distilled under low pressure at 40°C,...

Embodiment 2

[0034] (1) Preparation of SrTiO 3 and LaAlO 3 Double nanoparticles doped YBCO composite precursor:

[0035] 1) Preparation of YBCO precursor solution: Dissolve 0.845g of yttrium acetate tetrahydrate and 1.275g of barium acetate tetrahydrate in deionized water, add 3.5ml of trifluoroacetic acid, stir in a water bath at 60°C for 3 hours, and place the resulting solution in a rotary evaporator Upward distillation, the distillation temperature is 60°C, the white powder obtained is added to anhydrous methanol to redissolve, and the precursor solution A of Y and Ba salt is obtained; 1.497g copper acetate tetrahydrate and 2.582g α-methacrylic acid are added to anhydrous methanol In , fully reflux reaction at 90°C for 3h, then carry out three distillations on a rotary evaporator, the distillation temperature is 40°C, evaporate to dryness and dissolve with anhydrous methanol to obtain Cu salt precursor solution B; mix precursor solutions A and B , distilled under low pressure at 40°C...

Embodiment 3

[0043] (1) Preparation of SrTiO 3 and LaAlO 3 Double nanoparticles doped YBCO composite precursor:

[0044] 1) Preparation of YBCO precursor solution: Dissolve 0.845g of yttrium acetate tetrahydrate and 1.275g of barium acetate tetrahydrate in deionized water, add 3.5ml of trifluoroacetic acid, stir in a water bath at 60°C for 3 hours, and place the resulting solution in a rotary evaporator Upward distillation, the distillation temperature is 60°C, the white powder obtained is added to anhydrous methanol to redissolve, and the precursor solution A of Y and Ba salt is obtained; 1.497g copper acetate tetrahydrate and 2.582g α-methacrylic acid are added to anhydrous methanol In , fully reflux reaction at 90°C for 3h, then carry out three distillations on a rotary evaporator, the distillation temperature is 40°C, evaporate to dryness and dissolve with anhydrous methanol to obtain Cu salt precursor solution B; mix precursor solutions A and B , distilled under low pressure at 40°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com