Printing ink for advertising art design packing paper

A technology for printing ink and wrapping paper, applied in ink, household utensils, applications, etc., can solve the problem of single function of ink, achieve the effect of improving product performance and superior flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

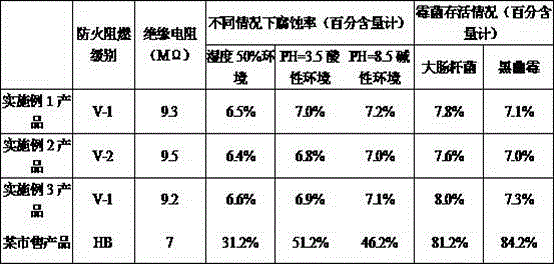

Examples

Embodiment 1

[0016] The advertising art design wrapping paper printing ink in this embodiment is composed of the following components in parts by mass: 16 parts of methylaniline, 14 parts of biguanide trioctylbenzenesulfonate, 14 parts of lead iodate powder, chlorothalonium 12 parts of clear water, 14 parts of dolomite powder, 14 parts of garlic oil, 12 parts of sodium phosphate, 14 parts of methyl isobutyl carbinol, 14 parts of methyl benzoylformate, 12 parts of polyether modified silicone oil, tert-butyl peroxide 12 parts of hydrogen oxide, 12 parts of sucrose, 14 parts of acrylonitrile-butadiene-styrene copolymer, 12 parts of nitrile rubber powder, 10 parts of dibasic lead stearate, 14 parts of hexabromocyclododecane, 12 parts of zinc borate hydrate, 10 parts of calcium hypochlorite, 12 parts of menthol, 10 parts of glass powder, 10 parts of diphenylmethane diisocyanate, 12 parts of molybdenum disilicide powder, 12 parts of beryllium oxide powder, paraffin oxide 12 parts, 12 parts of di...

Embodiment 2

[0022] The advertising art design wrapping paper printing ink in this embodiment is composed of the following components in parts by mass: 18 parts of methylaniline, 16 parts of biguanide trioctylbenzenesulfonate, 16 parts of lead iodate powder, chlorothalonium 14 parts of clear water, 16 parts of dolomite powder, 16 parts of garlic oil, 14 parts of sodium phosphate, 16 parts of methyl isobutyl carbinol, 16 parts of methyl benzoylformate, 14 parts of polyether modified silicone oil, tert-butyl peroxide 14 parts of hydrogen oxide, 14 parts of sucrose, 16 parts of acrylonitrile-butadiene-styrene copolymer, 14 parts of nitrile rubber powder, 12 parts of dibasic lead stearate, 16 parts of hexabromocyclododecane, 14 parts of zinc borate hydrate, 12 parts of calcium hypochlorite, 14 parts of menthol, 12 parts of glass powder, 12 parts of diphenylmethane diisocyanate, 14 parts of molybdenum disilicide powder, 14 parts of beryllium oxide powder, oxidized paraffin wax 14 parts, 14 part...

Embodiment 3

[0028] The advertising art design packaging paper printing ink in this embodiment is composed of the following components in parts by mass: 20 parts of methylaniline, 18 parts of biguanide trioctylbenzenesulfonate, 18 parts of lead iodate powder, 16 parts of clear water, 18 parts of dolomite powder, 18 parts of garlic oil, 16 parts of sodium phosphate, 18 parts of methyl isobutyl carbinol, 18 parts of methyl benzoylformate, 16 parts of polyether modified silicone oil, tert-butyl peroxide 16 parts of hydrogen peroxide, 16 parts of sucrose, 18 parts of acrylonitrile-butadiene-styrene copolymer, 16 parts of nitrile rubber powder, 14 parts of dibasic lead stearate, 18 parts of hexabromocyclododecane, 16 parts of zinc borate hydrate, 14 parts of calcium hypochlorite, 16 parts of menthol, 14 parts of glass powder, 14 parts of diphenylmethane diisocyanate, 16 parts of molybdenum disilicide powder, 16 parts of beryllium oxide powder, paraffin oxide 16 parts, 16 parts of dipropylene gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com