Anticorrosive electrolyte of lithium battery and obtained lithium primary battery

An electrolyte and lithium battery technology, applied in primary batteries, primary battery use/maintenance, electrolyte/electrode capacity ratio, etc., can solve problems such as battery failure, battery fire and explosion, battery life shortening, etc., to improve electrochemical performance. Performance, anti-corrosion effect, anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The positive electrode active material is made of iron disulfide, conductive agent acetylene black, graphite, and binder, and pure water is added to stir until uniform, and the dispersed positive electrode active material slurry is coated on the positive electrode aluminum foil current collector, and then cut into batteries after rolling the positive plate. After the positive electrode sheet is dried and completely removes the moisture in it, it is placed in an environment with a relative humidity below 1.0%, and a porous separator is inserted between the negative electrode (metal aluminum or lithium aluminum alloy) and the positive electrode sheet to separate the positive and negative electrodes. The membrane is wound into a cylindrical cell, and the wound cell is put into the battery casing (the casing is a steel casing, an aluminum casing or an aluminum-plastic film), and the battery is assembled by injecting liquid.

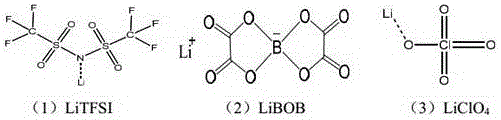

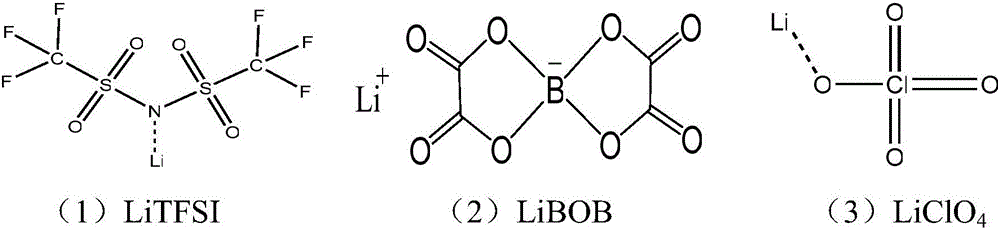

[0017] In the electrolyte part, lithium bistrifl...

Embodiment 2

[0019] In the same manner as in Example 1, carbon monofluoride is selected as the positive electrode material, lithium bistrifluoromethanesulfonimide LiTFSI, lithium bisoxalate borate LiBOB and lithium perchlorate are used as lithium salts, wherein bistrifluoromethanesulfonimide The mass proportion of lithium LiTFSI in the mixed lithium salt is 60%, the mass proportion of lithium bisoxalate borate LiBOB in the mixed lithium salt is 39%, the mass proportion of lithium perchlorate in the mixed lithium salt is 1%, the mixed lithium salt The concentration is 1.1M. Select ethylene carbonate EC, vinylene carbonate VC, dimethyl sulfite DMS and ethyl formate EF as electrolytes, wherein the volume percentage of ethylene carbonate EC is 30%, and the volume percentage of vinylene carbonate VC is 20% %, the volume percentage of dimethyl sulfite DMS is 20%, and the volume percentage of ethyl formate EF is 30%. The positive electrode, negative electrode, electrolyte and diaphragm of the pr...

Embodiment 3

[0021] In the same manner as in Example 1, manganese dioxide is selected as the positive electrode material, lithium bistrifluoromethanesulfonimide LiTFSI, lithium bisoxalate borate LiBOB and lithium perchlorate are used as lithium salts, wherein lithium bistrifluoromethanesulfonylimide The mass proportion of LiTFSI in the mixed lithium salt is 70%, the mass proportion of LiBOB in the mixed lithium salt is 29%, the mass proportion of lithium perchlorate in the mixed lithium salt is 1%, and the mass proportion of the mixed lithium salt The concentration is 1.2M. Select ethylene carbonate EC, dimethyl carbonate DMC, diethyl sulfite DES and ethyl acetate EA as the electrolyte, wherein the volume percentage of ethylene carbonate EC is 45%, and the volume percentage of dimethyl carbonate DMC is 5% %, the volume percentage of diethyl sulfite DES is 30%, and the volume percentage of ethyl acetate EA is 20%. The positive electrode, negative electrode, electrolyte and separator of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com